-

Shunhua Yolu, Jinan Şehri, Shandong

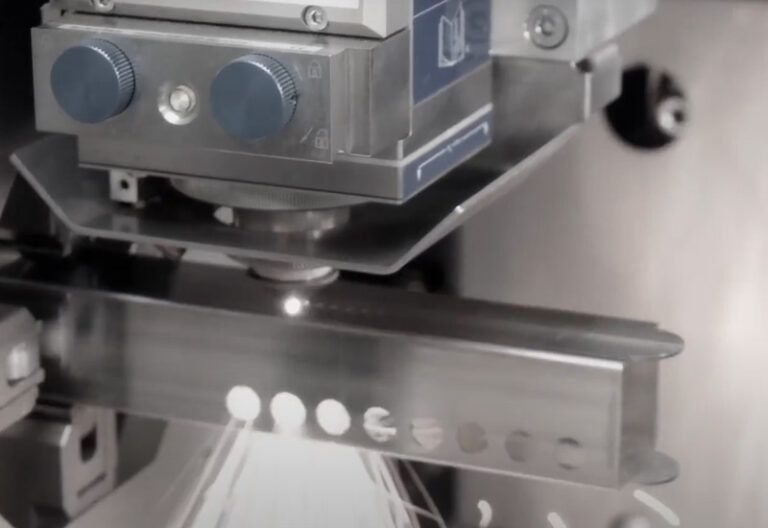

Fiber Laser Cutting Machine for Kitchenware Stainless Steel

Cut cleaner kitchenware stainless with a Fiber Laser Cutting Machine—bright edges, stable nests, less rework. Talk to BOGONG Laser, a trusted Laser Cutting Machine Manufacturer.

If you want clean edges and stable takt on food-grade stainless. This article will turly help you: what works, what bites, and how a Fiber Lazer Kesim Makinesi helps you push yield.

Why 304/316L stainless rules in kitchenware

Food contact needs corrosion resistance, hygiene, and easy wipe-down. That’s why kitchen sinks, hoods, panels, handles—most of them go stainless, most times 304, sometimes 316L for harsher cleaners or coastal installs. Clean surface, stable passivation, and consistent finish are the real goals.

What this means for cutting: protect the face, avoid heat tint, keep edges burr-free. If the edge looks brown or rainbow, users will call it “dirty,” even if it’s fine dimensionally.

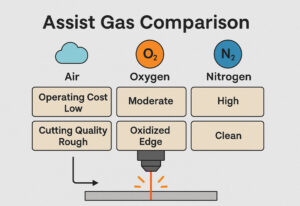

Assist gas choice: quality vs cost

You’ve got three common options: nitrogen, processed air, or oxygen. Kitchenware wants clean, bright, no oxide. Nitrogen’s the go-to for that bright edge; processed air can be good enough on many parts when you dial in, and the cost side looks nicer. Oxygen? Handy for certain steels, but you’ll fight oxide color—usually not what you want on visible panels.

Takeaway: when the part is visible or brushed, lean nitrogen. On inner parts or brackets, processed air might be okay—just watch dross and color. Don’t overthink; test a small nest and check wipe-off and Scotch-Brite behavior.

Quick table: assist gas vs appearance

| Assist gas | Edge look | Typical use in kitchenware | Notes you’ll care about |

|---|---|---|---|

| Nitrogen | Bright, clean, no oxide | Visible panels, brushed faces, mirror parts | Preferred for A-side aesthetics; great for wipe-clean finish |

| Processed air | Acceptable to clean, may need light touch-up | Inner brackets, non-visible frames | Lower running cost; test for burr/color before scaling |

| Oxygen | Oxide and color present | Select tasks (not common on A-side) | Use when you accept color or plan post-finish anyway |

Thin sheet reality check: speed is king, but stability wins

Kitchenware stainless is typically thin gauge. That screams for fast cycle, but chase speed too hard and you invite micro-burrs, “pepper” on the underside, or edges that snag during assembly. A smart Lazer Kesim Makinesi Üreticisi (such as BOGONG LAZER®) tunes for stable kerf evacuation and smooth lead-outs, not only fastest toolpath time. Speed that causes rework ain’t speed.

Shop talk: shorten pierce, use ramped lead-ins on tight geometry, and keep nozzle centering tight.

Protective film: cut it right, don’t melt the look

Brushed and mirror faces usually arrive with protective film. You can cut through film, no problem—if it’s laser-friendly and you pierce clean. Slow pierce or wrong duty and you’ll bubble the film, leave glue, or stamp a scar that shows after peel.

One rule: one-shot pierce, steady speed. If you see gummy residue, increase assist gas purity/pressure, verify nozzle condition, and check that lead-ins don’t sit on the cosmetic face.

Keep heat tint away: finish matters more than you think

Heat-affected discoloration might look “okay” under warehouse light, but customers spot it fast in a bright kitchen. Post-cut routine should include quick deburr, remove any tint on the visible side, and restore passivation—mechanical, chemical, or electro methods depending on your house rules. Overkill? Nope. It’s your brand on that panel.

When parts get long: coil-to-laser can save your back

Range hood bodies and long splash panels love coil feed. Decoiler + straightener + laser = fewer touches, less scratch risk, better material usage. Skeleton handling becomes predictable, and you keep fingerprints off the face. If you’re not ready for coil, at least run smart nesting with remnant tracking.

Claims, reasons, and what to do (with matching models)

| Claim (kitchenware stainless) | Why it matters | Shop-floor move | Suggested BOGONG model |

|---|---|---|---|

| Bright, oxide-free edges look premium and clean | Visible parts get judged by eyes, not calipers | Favor nitrogen on face-side parts; short pierce; tidy lead-outs | Fiber Lazer Metal Kesici |

| Film faces must survive cutting | Glue blisters = rework, scrap, angry QC | Laser-friendly film, one-shot pierce, no lead-ins on cosmetic areas | Konik Fiber Lazer Kesim Makinesi |

| Brackets and frames can balance cost/quality | Not every part needs the fanciest edge | Trial with processed air; inspect burr and color before scaling | 6000W-40KW fiber lazer kesim makinesi |

| Long panels hate extra handling | A scratch on brushed face is a return waiting to happen | Consider coil feed or at least larger blanks + stable stacking | Lazer Plaka ve Tüp Combo Fiber Lazer Kesim Makinesi |

| Tube rails and frames must fit first try | Burr inside tube = nightmare during assembly | Use tube-specific tooling, good purge, and microjoint strategy | Otomatik Yüklemeli Lazer Boru Kesme Makinesi |

Pain points we hear from kitchenware teams (and how to fix fast)

Film scorching on brushed faces

Usually a pierce + film issue. Try shorter pierce time, move lead-ins off the A-side, and confirm the film spec. If edges still sticky, inspect nozzle face and swap consumables. Don’t baby it—just swap.

Edge color on visible panels

You’re either starving gas or running too hot. Nudge parameters for cleaner evacuation and reduce dwell at turn points. Quick post clean (mechanical or electro) brings the shine back.

Tube cut mismatch at assembly

Use proper tube cut charts, align chuck grip to reduce push-pull marks, and use microjoints on short features so the part doesn’t jump. Small things, big win.

Why BOGONG Laser fits the kitchenware world

BOGONG LASER® is a Lazer Kesim Makinesi Üreticisi ve Lazer Kesim Makinesi Fabrikası serving global B2B users—metalwork, appliances, signage, electronics, crafts. We build cutters, engravers, cleaners, welders; we support OEM/ODM; and we back it with certifications (CE, ISO9001, SGS, FDA) for your compliance files. You want simple: stable machines, fast response, multilingual support, shipments to way more than a hundred countries.

Wrap-up

Kitchenware stainless needs a Fiber Laser Cutting Machine that respects the face. Keep edges bright, film intact, nests stable, and heat tint gone. Tune gas, mind the pierce, watch your nozzles, and don’t be shy with post-finish when the brand is on display. BOGONG Laser brings machines and support that play nice with stainless.

Want some help? Welcome to fill out the contact form to reach BOGONG—let’s talk your drawings, materials, and targets.