-

Shunhua Yolu, Jinan Şehri, Shandong

Customized 3D Fiber Laser Engraving Machine for Metal Crafts

Enhance your metal crafting with BOGONG's 3D Fiber Laser Engraving Machine. Achieve precise, deep, and versatile engravings on various metals with high-speed, low-cost solutions.

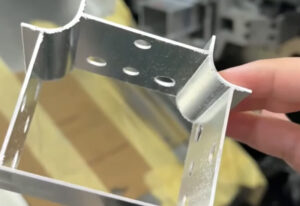

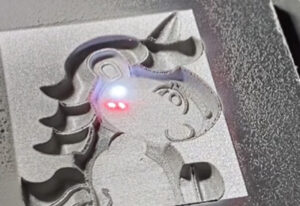

A Customized 3D Fiber Laser Engraving Machine for Metal Crafts is a specific piece of equipment that makes use of a high-intensity laser beam to inscribe three-dimensional designs onto different metal surface areas. It’s made for developing complex and distinctive patterns, reliefs, and variable depth inscriptions on curved and flat metal surfaces.

Why a 3D Fiber Laser Engraving Machine Rules

Laser engraving relocated from level, 2D marking to full-on 3D sculpting. You’re not simply scraping a surface– you’re shaping structures, sculpting depth, and also including anti-slip grip patterns. Right here’s why you’ll enjoy it:

Micron-level precision: Forget misaligned etchings on curved parts. A dynamic focus head lets you hit every contour, even on handles or rounded jewelry.

Versatile metal support: From aluminum signs to brass jewelry, fiber lasers handle it all—no swapping systems.

Temassız süreç: No tool wear, no mechanical stress. You get permanent marks without heat-buildup concerns or burrs.

Scalable throughput: Whether you run a single custom order or a 24/7 production line, beam quality and galvanometer speed keep cycle times tight.

Tailoring Your Machine with BOGONG Laser

BOGONG Laser fine-tune each engraving head, software package, and safety enclosure to match your shop’s quirks and throughput demands.

Deep vs Shallow Engraving: Pick Your Depth

Depending on your craft, you might need a delicate surface texture or a millimeter-deep mold. BOGONG’s deep-engraving module shifts the focal plane on the fly. You get:

Surface etch for branding or serial numbers.

Deep engraving for molds, dies, or tactile grips.

Materials Galore: From Aluminum to Steel

No more juggling CO₂ and fiber setups. A single BOGONG 3D fiber head adapts to:

Aluminum and alloys for signage and enclosures.

Paslanmaz çelik for tools and automotive parts.

- Brass and copper for decorative accents.

Machine Options

Want to dive into specific gear? Here are a few you might browse:

Tales from the Shop

A factory runs a small batch of custom knife handles. Each has a curved pommel and inlay grooves. They tried rotary attachments on a regular laser, but the depth varies and edges burn. With a Metal İçin 3D Fiber Lazer Gravür Makinesi, the five-axis galvo keeps the focal spot dead-on, delivering consistent cuts—even around tight corners.

And another factoery—a mold-making facility. They need crisp, deep textures inside tool cavities. Manual CNC slows throughput and wears bits fast. Swap in a fiber laser with dynamic focus, and you knock out micro-textures in minutes, no tool changes needed.

Picking the Right Laser Engraving Machine Factory

When you scout a Laser Engraving Machine Factory, watch for:

Accreditation credentials: CE, ISO9001, SGS—these show they follow global quality standards.

OEM/ODM yetenekleri: You want a partner who modifies optics, software, and enclosures for your precise specs.

Global support network: Quick spare-part delivery and multilingual tech docs maintain downtime marginal.

BOGONG Lazer ticks all these boxes. They’ve shipped to 160+ countries and powered over 9,000 projects—so their after-sales service is dialed-in.

Video Demo: High Speed 3D Laser Engraving Machine for Sale | Metal 3D Laser Engraver from China

And here’s a quick breakdown to help better understand:

| Senaryo | Meydan Okuma | BOGONG Feature | Fayda |

|---|---|---|---|

| Curved knife handles | Focus drift on rounded surfaces | 5-axis dynamic focus head | Uniform depth, zero rework |

| Textured mold cavities | Slow mechanical tooling | Deep-engraving focal shift | Faster cycles, no bit wear |

| Small serial numbers | Inconsistent mark legibility | High-resolution beam (DPI mode) | Sharp, permanent branding |

| Automotive trim parts | Heat-affected zones and discoloration | Low-heat pico-pulse control | Clean edges, no discoloration |

| Metal jewelry prototypes | Material switching complexity | Auto-tune wavelength & power | One-machine multi-metal flexibility |

Trick Attributes at a Glimpse

| Özellik | What It Means | Why You Care |

|---|---|---|

| Dynamic 5-Axis Scanning | Follows every curve | No more focus issues on complex parts |

| Deep-Engraving Mode | Adjustable etch depth | From surface logos to deep molds |

| Vector & Raster Dual-Mode | Switch on the fly | Ideal for mixed-style jobs |

| Galvo Speed & Beam Quality | High throughput, tight spots | Faster jobs, sharp details |

| User-Friendly Software Interface | Drag-and-drop layout tools | Lower training curve, fewer errors |

Overcoming Pain Points in Production

Even the best machine hits snags. Here’s how BOGONG helps you tackle them:

Alignment headaches: The built-in jig system docks parts in the exact same spot every cycle—no fudging.

Focus drift on polished surfaces: Auto-calibration routines reset focal distance before each run.

Maintenance downtime: Swappable laser modules get you back online without calling in a service tech.

Why you choose BOGONG?

Choose BOGONG means you will get:

Less rework: Consistent first-pass success means fewer wasted parts.

Higher throughput: Faster cycles let you take on more jobs without hired help.

Broader service offering: Offer deep engraving, fine marking, and multi-material work, all with one machine.

Lower operating cost: Fiber lasers run cooler and use less power than CO₂ at the exact same result.

Lasting reliability: Laser diodes rated for tens of thousands of hours maintain your line humming.

Toparlıyoruz

All in all, going custom with a 3D Fiber Lazer Gravür Makinesi from BOGONG Laser gives you the flexibility, precision, and uptime you crave.

Fill out the contact form on our site, and let’s chat about your next project.