-

Shunhua Road, cidade de Jinan, Shandong

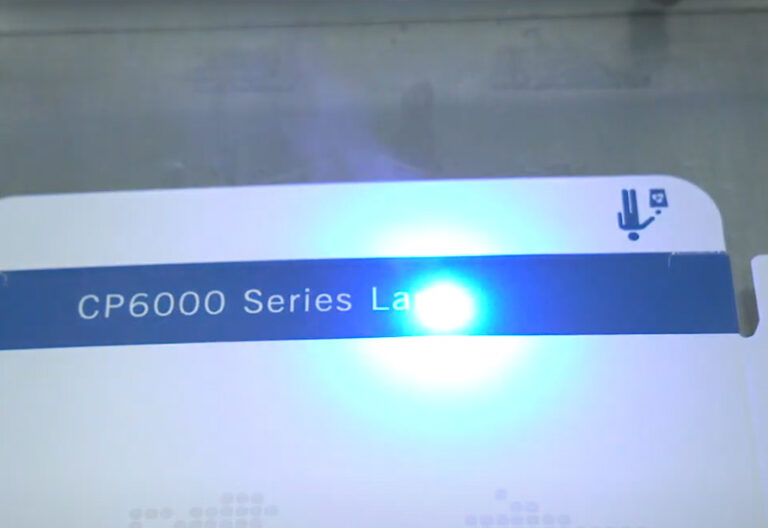

UV Laser Marking Machine for Cosmetic Glass Bottles

UV laser marks on cosmetic glass—clean edges, permanent codes, stable lines. Work with BOGONG LASER®: flexible UV/3D options from a global Laser Marking Machine Manufacturer.

Why brands shift from ink to UV laser

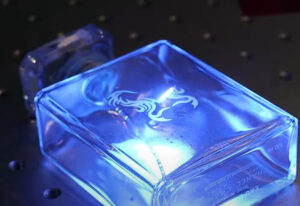

Ink means bottles that smell like solvents, date codes that rub off, and constant consumables. UV laser marking, by contrast, is non-contact, clean, and produces permanent, high-contrast marks on glass. That permanence is what QC, QA, and your compliance team want. And yes, the look—crisp edges, fine lines—sells the product at arm’s length.

Also: UV is “cold” compared to longer-wavelength lasers. Less heat affected zone (HAZ), fewer micro-cracks, fewer chip-outs at the edges. On premium flacons or frosted glass where defects scream, that’s gold.

What “cold” actually means here

Short wavelength. High absorption in glass surface. Energy couples near the skin of the material rather than dumping heat deep inside. In practice, it’s easier to hold edge quality and readability while keeping your bottle intact.

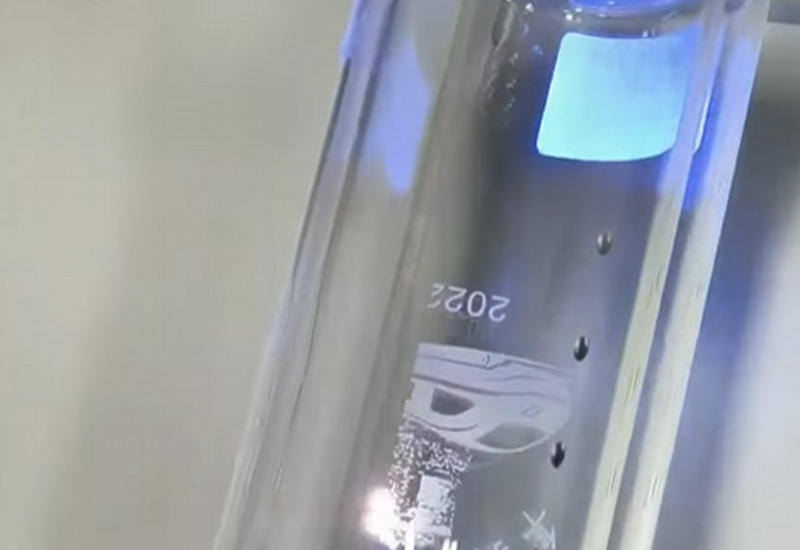

And here is a video demonstrates UV marking effects on glass, plastic, and metal.

Mark types that actually ship

Shelf-visible ID: lot/batch, MFG/EXP, trace codes that don’t fade after handling or transport.

2D codes: when you need compact data, internal tracking, or CRM join points.

Brand micro-details: tiny logos, fine serif text on the heel or the shoulder without turning chalky.

Light decorative effects: when you want a classy, matte touch without sandblasting the whole panel.

Where the pain shows up on the line (and how to kill it)

Glass variance: Different batches, different coatings, different anneal. Translation: inconsistent absorption and edge behavior.

Fix: run a quick DOE—map speed/shot density/frequency windows, lock a recipe per finish.Focus drift on curved bottles: Shoulders and tapers mess with depth of field.

Fix: go 3D scan head or Z-tracking if the SKU geometry demands; or add your simplest puck/fixture and set fiducials. Galvo likes stability.Micro-crack paranoia: Team sees sparkle under bright light and panics.

Fix: do a basic MSA for visual criteria, standardize illumination angle, use the same lint-free cloth rub test for everyone.Code contrast on frosted vs clear: Frosted glass gives easy contrast; clear needs tuned parameters and code placement.

Fix: avoid highlight zones; add a subtle brand cartouche panel if design allows. Mark where the bottle helps you.Upstream coating surprises: A “new eco coat” shows up and your mark goes flat.

Fix: leverage a formal change-control: incoming sample, quick capability check, approve or kick back. No stealth swaps.

Commercial value, not just marks

Brand trust at the shelf: high-contrast codes and tidy edges look expensive. That’s equity.

Traceability that actually works: permanent marks stick through cold chain, makeup smudges, cleaning cloths.

Lower running hassle: no ink, no makeup, no solvents. EHS smiles, purchasing relax.

Better OEE: fewer stoppages from nozzle drama, less cleanup, more stability run-to-run.

UV vs other Laser Marking Machine options

| Criterion | UV Laser on Glass | CO₂ Laser on Glass | Fiber/MOPA on Glass |

|---|---|---|---|

| Edge quality | Crisp, fine, “clean” | Grainier, sand-blast vibe | Not the first pick for bare glass |

| Heat impact | Lower, “cold-ish” | Higher at surface | Tends to over-heat glass |

| Look & feel | Premium, detail-friendly | Decorative matte possible | Usually for metals/plastics |

| Best use on cosmetics | Batch, 2D, micro-logo | Decorative texture panels | Caps, foils, metal parts |

What to ask from your Laser Marking Machine Manufacturer

You want a partner, not a box-pusher. A good Laser Marking Machine Factory will help you:

Qualify your glass set (clear, frosted, coated, tinted).

Run sample sets against your real bottle geometries, not just flat coupons.

Provide 3D marking options for shoulders, tapers, and emboss zones.

Offer fixtures & vision so operators aren’t playing darts with alignment.

Share a sane PM schedule (optics cleaning, airflow, basic checks).

Document your window (you own the recipe, not just the result).

Field-tested scenarios

Fragrance heel code: tiny alphanumeric tucked at the base. UV nails legibility without a chalk halo.

Serum bottle 2D code: square code on a slight curve. With 3D UV scanning, contrast stays even, and scanning success jumps.

Limited edition micro-logo: brand motif on shoulder—UV maps tight curves with a neat edge.

When real glass shows up, UV looks cleaner and keeps the peace between design and production.

Process control

Lock a DOE: quick grid of speed/shot density/frequency—not forever, just enough to bracket each finish.

Fix your focus: If SKU geometry varies a lot, don’t cheap out—go 3D or fixtures.

Standardize inspection: viewing distance, angle, and wipe test. Avoid lighting roulette.

Close the loop: tie a vision read (or handheld verifier) to your PLC. Bad code? Auto-reject.

Where BOGONG Laser slots in (and why it matters)

BOGONG Laser is a Laser Marking Machine Manufacturer with the full spread—UV, fiber, CO₂—so you’re not forced into one wavelength dogma. If your portfolio includes caps, foils, metal collars, and glass, a mixed toolkit beats a single hammer. You can browse the whole Máquina de marcação a laser lineup and narrow down quickly by substrate.

Máquina de marcação a laser UV – the baseline UV workhorse for crisp codes on cosmetic glass.

Máquina de marcação a laser UV 3D – when you have shoulders, curves, emboss areas, and still need uniform contrast.

Máquina de marcação a laser CO2 – if you’re planning decorative matte panels or frosted effects alongside codes.

Máquina de marcação a laser – sub-category view to compare UV options fast.

This way you can stage a small pilot on your top three SKUs, qualify recipes, then roll across the family. Less drama, more throughput.

PERGUNTAS FREQUENTES

Will UV slow my line?

Not if you match code size and density to reality. Do a pilot on your worst-case SKU. The line tells the truth.

Will marks scratch off?

Proper UV marks on glass hold up against normal handling and wiping. If yours don’t, recipe or focus is off. Fixable.

What about curved perfume bottles?

Use 3D UV or proper fixtures. Don’t force a flat recipe onto a dome.

Do I need vision?

If you ship millions, yes. It keeps humans from policing tiny codes under harsh lights.

Wrap-up

For cosmetic glass, UV laser marking is the clean, reliable path: premium look, stable edges, permanent codes, and fewer headaches on the floor. When you need matte decoration, bring CO₂ into the mix. When you need metal collars or caps, fiber/MOPA joins the party. Multi-tool beats one-tool.

If you’re ready to test with a seasoned Laser Marking Machine Manufacturer, BOGONG Laser can set up quick samples on your bottles and help you lock a recipe before scale. Start from the UV lineup, keep the process tight, and let the bottles sell themselves.

Please fill the contact form on bogong, We’ll reply fast.