-

Shunhua Road, cidade de Jinan, Shandong

Laser Welding in 5G Telecom Equipment Manufacturing

Laser welding for 5G: tighter seals, cooler joints, faster lines. See BOGONG LASER® solutions for RF lids, Cu–Al busbars, and outdoor housings—practical, scalable.

How laser welding earns its keep in 5G builds

Hermetic sealing for RF/optics

Small HAZ means you can weld a perimeter seam near filters, LNAs, or ferrules without cooking them. The seam becomes the barrier—no creeping adhesives, fewer leak paths, easy helium leak-test thinking.Cu–Al electrical joints without drama

5G power trains still love copper; housings and heatspreaders often go aluminum. That interface is tricky. Laser lets you modulate the puddle and keep brittle IMC layers in check. Wobble (oscillation), angle-in, sometimes an interlayer—doable stuff on the line.

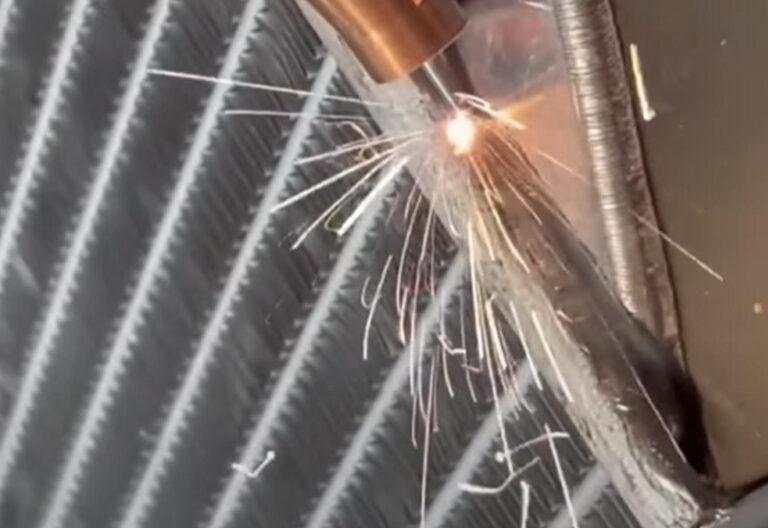

Check out this short video — BOGONG’s laser welder moves smoothly between copper, stainless steel, and aluminum, switching from welding to cleaning to cutting in one setup. It proves what we just talked about: laser welding doesn’t really care what alloy you feed it. If you control energy and focus, you can handle mixed metals with the same machine. That’s a real plus for 5G assemblies using copper busbars, aluminum housings, and stainless frames.

Outdoor enclosures that work well in a storm

Welded seams remove the “capillary highway” that screws + oversize gaskets sometimes leave. Tie that seam to breathers and surface finish, and you’ve got an high mindset without over-torquing hardware.Automation and inline control

Depth monitoring, stable keyhole, decent fixturing—this is how you go from lab to thousands of parts.

What trips people up (and how to untrip it)

Porosity & spatter — Clean the joint. Lower the puddle violence. A tiny preheat helps. Wobble helps. Also: don’t overdrive on high-reflective alloys; try angle-in or a different coupling trick.

Warped lids — Too much heat input, uneven clamping, or long uninterrupted bead. Break the seam into segments, use jump welding, add heat sinks.

Back-reflection panic — Use proper fiber delivery, protective windows, and angle tilt. Keep optics clean; swap consumables on schedule.

IMC creep at Cu–Al — Control mixing. Lap geometry with right overlap, mild oscillation, interlayer where appropriate, verify with cross-sections before you scale.

Inconsistent depth — Z-tracking and focus control. Build a quick laser-depth correlation curve and lock it with inline monitors.

A simple, shop-floor table

| Pain point (5G shop) | Why it happens | No-BS fix on the line | Where a Laser Welding Machine helps | Nice fit from BOGONG |

|---|---|---|---|---|

| RF lid keeps leaking after humidity/thermal | Discontinuous seam, contamination, warped cover | Degrease, flat clamp, segment the bead, short dwell between legs, helium check | Stable, narrow HAZ seam that stays sealed | Máquina de solda a laser portátil for flexible jigs; CCD models for small cans |

| Cu–Al busbar joint runs hot | Brittle IMC layer, poor mixing control | Wobble oscillation, smaller overlap, consider Ni interlayer, angle-in to boost coupling | Tunable energy and spot size; parameter recipes are repeatable | Soldador a laser portátil 3 em 1 lets teams clean → weld → post-polish in one gun |

| Spatter painting the optics | Violent keyhole, dirty surface, wrong focus | Shorter pulse or QCW-style approach, clean parts, tweak focus to calm the pool | Cleaner bead with less rework and fewer rejects | Máquina de solda a laser portátil com resfriamento a ar for light cells without chiller sprawl |

| Tight geometry, tiny window | Big torch can’t reach, heat bleeds | CCD assist, micro-torch, minimal heat input passes | Benchtop, small-field welds near sensitive parts | Mini máquina de solda a laser 200W Pro com CCD for delicate benches |

Some cases we have fixed before

Outdoor unit re-seal, quick save

Field crew spotted a tiny weep on a perimeter seam after a storm. They cleaned, clamped flat, and ran a light pass with a Máquina de solda a laser portátil. Short dwell, quick polish, done. Unit went back up same day. This is where a portable Laser Welding Machine earns its keep—fast touch-ups without dragging a chiller across the yard. In a Fábrica context, the same handheld keeps rework from blocking the main cell.

RF can that hated heat drift

A small lid sat too close to filters; long beads warped it. Switching to segmented arcs on a bench rig with vision control fixed it. The Mini máquina de solda a laser 200W Pro com CCD let the team track the seam through a tiny window and keep HAZ tight. Result: alignment stayed stable, leak checks stopped failing. That’s the precision side you expect from a serious Manufacturer toolset.

Cu–Al busbar joint running warm

The interface was stiff and a bit brittle. They added a light oscillation and cleaned oxides first using the cleaner head on the Soldador a laser portátil 3 em 1, then welded, then quick polish—same gun, no station swap. Wetting improved, fracture faces stopped looking sandy, and current path ran cooler under load. One operator, one Laser Welding Machine, fewer handoffs.

- Tight space, no floor chiller

Maintenance bay had limited power and zero water loop. An Máquina de solda a laser portátil com resfriamento a ar handled bracket seams and enclosure tabs without the usual hose jungle. Angle-in approach calmed spatter, and the lighter body made awkward reaches less painful. Handy for small electronics corners where carts just don’t fit.

Why handheld + mini-CCD is a strong combo in telecom plants

A small checklist before you press the pedal

Clean metal (really clean).

Clamp flat. Keep heat paths short.

Start with a coupon; lock the focus and the bead shape.

Run short segments; watch color, watch plume.

Check one: cross-section or leak, whichever matters most for that joint.

Save the recipe. Don’t rely on “I remember”.

Where BOGONG helps

BOGONG LASER® keeps it simple: give your team tools that work, then get out of the way. In a Factory, you’ve got two tempos—flexible rework and steady line build. A handheld Laser Welding Machine covers brackets, door seams, odd angles, field fixes. The mini CCD bench unit handles small RF lids and optical cans where the window is tiny and the risk is big. Same idea, different scale.

The point isn’t flashy specs. It’s repeatable joints, fewer leaks, and fewer NCMRs. BOGONG, as a Manufacturer, ships practical options that slot into your existing fixtures and SOPs.

Wrap it up

Laser welding wins in 5G not because it’s trendy, but because it controls heat, closes leak paths, and keeps resistance honest. Pair sane geometry with steady parameters, clamp right, and verify inline. Do that, and the weld becomes the least dramatic part of your build. Which is kinda the goal.

Fill out the contact form to talk with BOGONG, we will reply fast.