-

Shunhua Road, cidade de Jinan, Shandong

Laser Cleaning Machine for Bridge Paint Removal

Bridge paint removal without chaos: laser cuts waste, containment, and downtime. Explore pulse/CW tools from BOGONG LASER. Ask for a fast pilot plan.

Why bridges care about laser, not only blasting

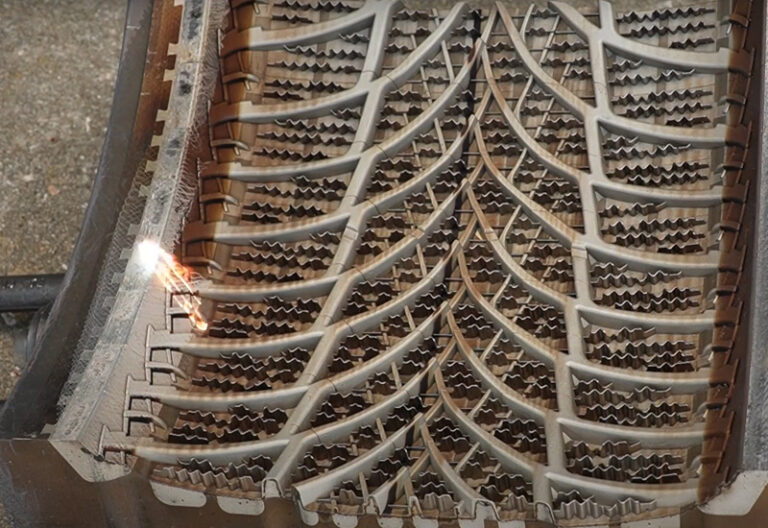

Old bridge paint is stubborn. It sticks around bearings, gusset plates, rivet lines, and weld toes. Blasting still has its place, sure. But it brings giant containment, lane closures, grit waste, and housekeeping that never ends. A Máquina de limpeza a laser attacks a different slice of the work: high-control removal with way less mess, minimal traffic disruption, and tidy flows.

Laser makes sense where waste, containment, and access hurt

Laser ablation vaporizes or ejects old coating inside a tiny footprint. Pair the handheld head with fume extraction and multi-stage filters. You’re not dumping bags of blast media; you capture particulates at the source. Crews like it on bearings, rivet fields, and those “nasty edges” where blasting overshoots and cleanup goes bananas. Fewer tarps. Often no big scaff tubes raining grit. Traffic keeps rolling.

For localized removal on steel bridges, laser is cleaner, quieter, and less disruptive than grit blasting.

For very large surfaces, laser alone is slower. Think hybrid.

Evidence and what it means

| Argumento | What crews actually see | So what for owners / GCs |

|---|---|---|

| Less waste to manage | No drums of spent grit; mostly filtered dust captured in the unit | Lower disposal hassle; easier compliance; fewer “oops” moments |

| Smaller containment | Often no full-tent; localized capture with the extractor hood | Shorter setup, faster move-ups, fewer lane closures |

| Edge control | Tight beam follows bolts, fillets, and weld toes | Cleaner substrate where coatings usually fail first |

| IH exposure managed | With proper extraction and PPE, airborne levels stay controlled | Safer windows; easier scheduling for overtime/night ops |

| Surface integrity | No mechanical peening; base steel stays calm | Good for sensitive details; less risk of collateral damage |

| Speed trade-off | Laser isn’t a productivity monster on huge flat fields | Use it as a scalpel: details, punch-list, pre-weld windows |

On-site pain points and quick fixes

“My bearing seats are a mess.”

Use laser to de-coat the footprint without sand everywhere. Keep a shroud tight to the work, run the extractor hot, and don’t chase shiny across the whole sole plate.“Rivets and gussets eat my schedule.”

A handheld head lets you walk around rivet heads, along the heat-affected zone, and into gusset corners. No grit ricochet drama. Go in passes; don’t park the beam—move it smooth, like welding.“Containment eats my budget.”

Laser cuts scaff and tarp scope on spot repairs. For bigger spans, you still need access, but you’re not bagging tons of media later. Fewer hose-downs, fewer night-shift cleanup marathons.“We can’t shut a lane, boss.”

Laser is compact and quiet-ish. With a proper traffic plan, you can work shoulders, abutments, and under-bridge bays without full closures. Be smart; don’t crowd the live edge.“Inspector wants clean steel.”

Laser tends to leave a uniform, clean substrate. If your spec needs a profile, do a light mechanical key afterward. Document pass sequence, keep before/after pics, keep QA simple and tidy.

Where laser fits in the bridge lifecycle

Spot remediation before overcoat—treat rust spots and failed edges without blasting an entire bay.

Pre-weld/window prep for studs, clip angles, or bracket installs where you need bare steel quick.

Lead-paint hot zones where you want lower airborne mess and high-confidence capture.

Safety and compliance

Treat the fume extractor as critical path gear; keep filters fresh and logs tight.

Run a laser safety perimeter; lens and beam discipline matter.

PPE stays on even when it “looks clean”. Hygiene wins audits.

Don’t chase perfect whiteness if the spec doesn’t ask for it. No over-clean flex.

If the spec calls for profile, confirm with the agreed method; laser leaves clean steel, not always an anchor pattern.

Which Laser Cleaning Machine to consider

Máquina de limpeza a laser de pulso de 1000 W — when you need headroom for stubborn coatings and pulse control on steel details.

Máquina de limpeza a laser de pulso de 500 W — lighter, handier for spot work and punch-list.

Máquina de limpeza a laser de pulso de 300 W — compact footprint for tight access and travel-light crews.

Máquina de limpeza a laser de fibra CW — continuous-wave option for certain oxide/rust jobs where dwell style differs.

Máquina de limpeza a laser tipo maleta com carrinho — roll-up mobility; good for scattered locations under the deck.

Quick comparison

| Product style | Typical bridge scenes | Crew comment |

|---|---|---|

| Pulse handheld (compact) | Bearings, rivet rings, flange edges, splices | “Easy to carry, no grit rain on my vest.” |

| Pulse higher-power class | Heavier build-ups, old stubborn systems | “Gives me margin. I ain’t pushing too hard.” |

| CW handheld | Oxide and scale in controlled scenes | “Different feel; set expectations on finish.” |

| Trolley case form | Under-bridge hop-scotch, night ops | “In and out before traffic plan blinks.” |

How to write the spec

Scope laser for small-area removal and detail prep. Don’t force it onto wide-open production.

Require extraction with multi-stage filtration and waste tracking.

Define acceptance: cleanliness for overcoat or weld prep; profile only if needed.

Keep QA light but real: photo logs, pass counts, simple wipe checks where relevant.

Traffic plan: show how laser lets you keep lanes open or closures short.

Hybrid allowance: let the contractor blend laser + bulk method.

Why BOGONG LASER shows up in this conversation

BOGONG LASER is a Laser Cleaning Machine Factory and Laser Cleaning Machine Manufacturer with a global B2B footprint—cutting, marking, cleaning, welding. Certifications include CE, ISO9001, SGS, FDA, France BV. For bridge owners and contractors, that means:

One supplier, many scenarios—pulse and CW cleaning options, plus cutting/marking/welding.

OEM/ODM capability—if you’re an integrator or need special nozzles, cable lengths, trolley tweaks.

Multilingual and shipping to lots of countries—handy when the asset manager sits in one place and the contractor in another.

Industry range—metalwork, auto, signage, wood, electronics.

Final stance

Laser won’t replace blasting on giant flats; don’t try to force it. But if you’re tired of tents for a palm-sized patch, laser is the grown-up move. It keeps work precise, keeps waste low, and keeps traffic cops off your back. Put it in your bridge toolbox for rivets, bearings, edges, and the never-ending punch-list. That’s where it pays for itself in sanity.

Welcome to fill out the BOGONG contact form, and we will reply you fast.