-

Shunhua Road, cidade de Jinan, Shandong

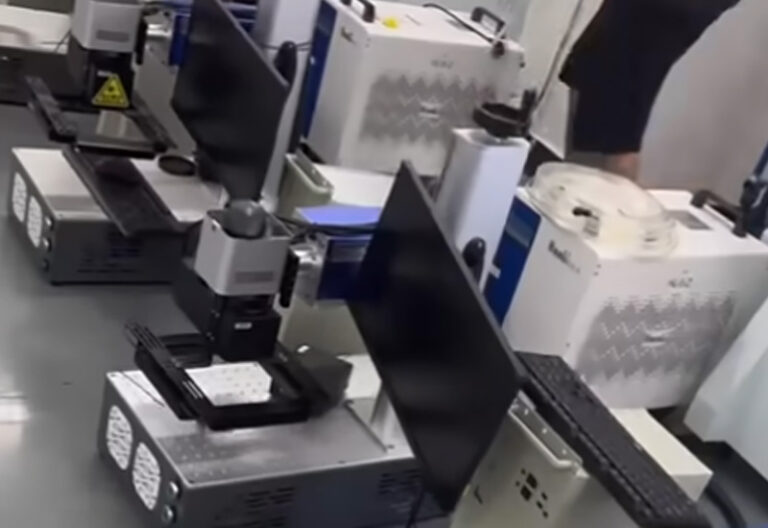

Fiber Laser Marking Machine for PCB Traceability Codes

PCB traceability with fiber/UV laser marking: real factory tips, code design, verification, and MES flow. Explore BOGONG LASER options and get a fast consult.

This piece walks through what works in a live SMT line, how fiber fits, where UV still wins, and how to lock better first-pass read rates without slowing the conveyor.

Why laser marking for PCB traceability?

Laser marking puts a permanent 2D code on the board. No labels peeling, no ink smearing after wash. Codes stay readable through reflow, cleaning, packing, RMA. That’s the whole point: a stable identity that your MES can follow from panel in to box out.

On trace data, think simple and robust: lot/serial, route step, time stamp, and any defect hooks you need for root-cause later. Put it into a Data Matrix or QR, place it where the camera can see after each key process, and you’re already ahead.

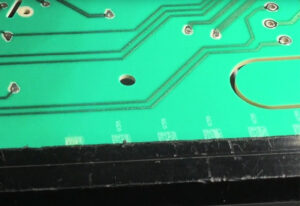

Pain point this solves: “Codes fail after conformal coat” or “can’t scan post-wash.” With the right recipe, laser marks read clean even on tricky masks and clear coats.

Fiber vs. UV vs. CO₂ — what’s actually practical?

You don’t pick a laser by vibe. You pick by substrate, contrast need, and takt reality.

| Laser type | Best fit on PCBs | Mark look & risk | When I’d choose it |

|---|---|---|---|

| Fiber (near-IR) | Bare copper features, metal parts, many solder masks | Fast cycles; can show more heat on sensitive areas; contrast depends on mask color | You want speed, low upkeep, compatible mask, and stable MES stats |

| UV (“cold” marking) | Solder mask, delicate coatings, small high-contrast codes | Crisp micro-marks with minimal surface impact | You need tiny modules, high contrast, or fragile surface |

| CO₂ | Organics/plastics, some mask colors | Good on specific polymers; less common for tiny PCB DPM | Niche stacks where CO₂ just pops better |

Mark quality, speed, and accuracy matter

Inline is everything. If the marker can’t meet the conveyor and the vision can’t find the window, you’ll back up the line.

What to expect from a good machine:

Placement: fiducial-based alignment so the code lands inside the mask window even if the panel drifts.

Verification: built-in camera to grade and reject before the board leaves the station.

MES handshake: pass/fail, code content, image receipt pushed into your system.

Protect first-pass read rate. Put “verify then pass” logic in the cell.

Code types and placement that won’t bite you later

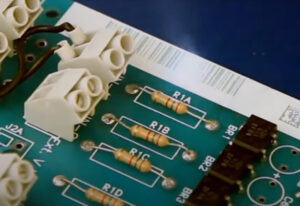

2D Data Matrix is the workhorse. Dense, tolerant, great for small windows. QR also fine if your enterprise standard says so.

Quiet zone matters. Leave a neat border around the code. No copper pours crashing the edge.

Mask windows placed where all your downstream cameras can see (AOI, ICT, final).

Content discipline: serial, lot, route, and one or two fields your QA actually uses. Keep payload tight so modules stay large enough to scan.

Mini-cases

Conformal Coat, Keep the Contrast

Clear coat turned codes milky, so the team moved the mark into a small mask window and graded it in-station; the inline cell used the Máquina de marcação a laser de fibra multifuncional to print, verify, and hand data to MES—no unreadables leaking downstream. That’s a clean fix a Factory can live with from a Manufacturer who knows takt.

High-Mix Colors, One Machine That Adapts

Masks kept changing (green, blue, matte black), so operators can run a two-recipe playbook: fiber for friendly masks, fine recipe for tricky coats; the base unit—Máquina de marcação a laser de fibra de 30W—handled most lots while the rest routed to models in the Marcador a laser de fibra family, and MES logged which recipe/source made each code. Simple flow, less arguing at pack-out.

Warped Panels, Accurate Placement

A slight bow nudged codes off the keep-out, so vision locked on local fiducials and a stable Z kept focus true; an inline verify blocked escapes right there, using a Laser Marking Machine with 3D motion like the 3D Fiber Laser Engraver for Metal, and for fast re-marks on carriers the tech just grabbed a Máquina de marcação a laser de fibra portátil de 20W, 30W, 50W. It do matter to check early.

Practical table: from “we think it’s fine” to “it scans every time”

| What to check | Why it matters | What good looks like |

|---|---|---|

| Mask color & chemistry | Drives contrast; some masks darken differently | Stable, high-contrast mark visible at inspection |

| Focus & power window | Too hot = halo; too soft = low contrast | Clean edges, no charring, repeatable look |

| Fiducial strategy | Compensates panel drift/warp | Marker locks to board, not to hope |

| Quiet zone & size | Tiny modules die first | Camera decodes fast, no retries |

| Verification step | Protects downstream | Graded in-cell, bad codes stopped early |

| MES fields | Garbage in, garbage out | Short, consistent payload your team actually uses |

Cost/quality trade-offs

Single-source cell (fiber only): simplest to own; great when your mask and design cooperate.

Dual-source cell (fiber + UV): more flexible for high-mix; pay a bit more in integration, earn it back in fewer rescans and less rework.

Verification camera quality: don’t cheap out. A clean, consistent grade avoids line debates.

MES integration once, use everywhere: one structured payload lets Production, QA, and after-sales all look at the same truth. No screenshots in chat groups, please.

Quick comparison table you can use

| Decision point | Fiber answer | UV answer | What your team notes down |

|---|---|---|---|

| Substrate sensitivity | Good on copper & many masks | Best on delicate coats | UV for fragile, fiber for robust |

| Contrast on dark mask | Can vary by recipe | Usually high | Try UV first if contrast is king |

| Takt pressure | Comfortable | Also fine with right setup | Both ok when configured well |

| Ownership/maintenance | Simple | Slightly more involved | Plan PM slots, keep spares |

| Future-proofing | Add UV later if needed | Start UV if you know it’s tricky | Leave space for second source |

Troubleshooting cheat sheet

| Symptom | Likely cause | Try this first |

|---|---|---|

| Low contrast after wash | Detergent or dwell too hot | Tweak wash recipe; mild power bump or slower speed |

| Halo or charring | Too much energy density | Step down power; re-focus; tighten passes |

| Random unreadables | Panel drift, shaky fixture | Add/support fiducials; check clamp vibration |

| Glare in verify image | Lighting angle wrong | Diffuse or polarize; nudge camera angle |

| Great at AOI, fails at final | Code blocked post-assembly | Move code window; add second code on keep-out |

Wrap-up

Fiber is excellent for many PCB traceability cases—fast, stable, easy to own. UV is your friend when the surface is touchy or you need tiny, crisp codes. The winning recipe is less about the logo on the cabinet and more about fiducials, verification, and a payload your MES can love. If you keep those tight, your boards scan first time, every time. That’s how you keep the line moving and audits calm.

BOGONG LASER can help you pick the right source, vision, and workflow. We’re a Manufacturer that ships globally and supports real Fábrica constraints—MES handshakes, safety, and service that shows up.

Welcome to fill the BOGONG contact form, we will always at your service if you have any questions.