-

Shunhua Road, cidade de Jinan, Shandong

Customized Tube Laser Cutting Machine for Bicycle Components

Build cleaner bike frames with customized tube laser cutting—bevels, tabs/slots, routing holes, less jig time. BOGONG Laser specs, OEM/ODM, global support.

A customized tube laser cutting machine for bike elements makes use of a high-powered, computer-controlled laser to precisely reduce and shape metal tubes for bicycle frames, forks, and other get rid of high precision and rate. These machines make it possible for the creation of intricate styles and customized features that are hard or impossible with standard approaches, causing more effective manufacturing, decreased waste, and the capability to fulfill specific customer demands for individualized bikes.

Why tube laser on bike parts

One-pass bevel + mitre + holes = fewer setups, fewer chances to mess it.

Tab-and-slot joints act like “self-jigs”—parts snap in, tacks go fast.

Thin HAZ and consistent kerf mean nicer weld puddles and less distortion.

Real nesting on round/square/oval tubes saves stock and keeps remnant tidy.

Scenarios from the bike bench

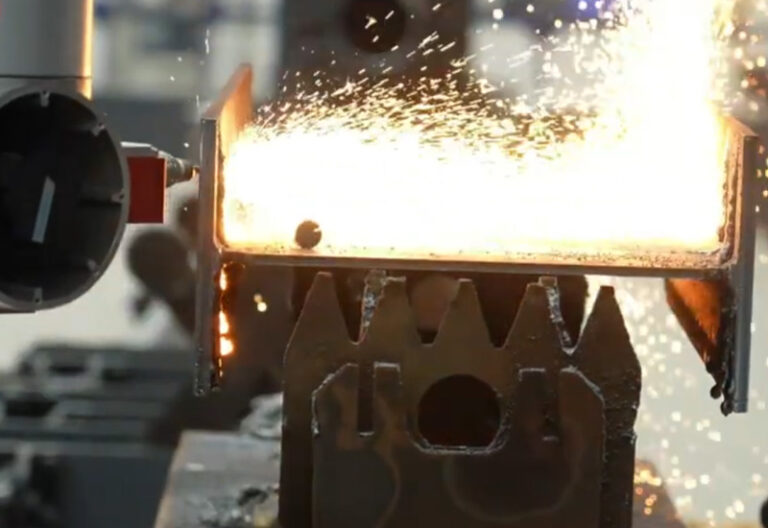

Bevel + mitre in one go

You want seat-tube to top-tube fit-up to sit flush without noon-till-night filing. A tube laser lets you cut the mitre e the weld-prep bevel in the same cycle. Lead-in/lead-out, pierce timing, nozzle centering—dial those and you get clean edges that weld sweet.

And here is a video shows how BOGONG laser cutting machine working.

CORTE DE BEVEL por máquina de corte a laser de fibra | Corte de ranhuras, chanfro por cortador a laser de fibra

Tabs & slots = jig-lite assembly

Put small tabs on one tube, slots on the mate. Now the joint self-locates. You dry-fit on the bench, hit two tacks, and it stays put. This is how you cut fixture time without cutting corners. Shops call this “joining aids.”

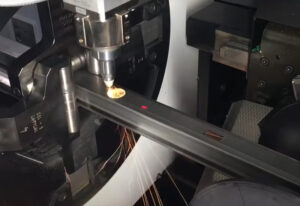

Hidden ports: routing holes done right

Brake hose ports, Di2/UCK wire, bottle bosses, internal stuff—make those holes/clips in the same hit as the mitre. Use tiny micro-joints if the cutouts would otherwise fall inside the tube during cutting, so you don’t play “shake the tube” later.

Thin-wall materials without tears

Stainless, Ti, aluminum—thin wall wants low heat input and sharp focus. Keep assist gas clean and coaxial, run conservative pierce, and watch edge taper. You’ll see less blueing, less edge crumble, less post-op. Back-purge for stainless as usual; laser doesn’t remove weld discipline.

Offcuts, tails, and remnant control

Bike tubes are short compared to structural pipe. You don’t want a pile of awkward tails. Use remnant management in the CAM so you leave usable pieces, not expensive scrap art.

Bend-then-cut or cut-then-bend?

For straight tubes, cut first. For pre-bent chainstays/seatstays, probe the contour or fixture to a repeatable zero, then trim to length/angle. Either way, aim for “zero-clamp regrip”—handle the tube once.

What problems it actually solves

| Bike part / purpose | Tube-laser move | Shop pain removed | Notes from the floor |

|---|---|---|---|

| Head tube ↔ top/down tube mitres | One-pass mitre + bevel | Hand filing, angle creep | Put small land on bevel so weld toes live happy |

| BB shell mates | Precise saddle cuts | Gap chasing | Short lead-in, minimal spatter = nicer root |

| Internal routing | Slotted/round ports | Drill wander, burr city | Use micro-joints to keep cutouts from dropping inside |

| Dropout bridges & gussets | Tabs & slots | Jig time, skew | Self-locating—tack, flip, finish |

| Rack/fender mounts | Perimeter holes | Alignment headache | Mark hole centers laser-true; tapping later is chill |

| Ti/SS thin wall | Low HAZ cut | Edge burn, distortion | Keep nozzle centered; assist gas matters a lot |

Choosing the right laser cutting machine for bike work

Bevel capability for weld-prep

If you do weld-ready mitres daily, a bevel-capable head saves hours of hand prep. See Máquina de corte a laser de fibra chanfrada for that use case.

Plate + tube combo for brackets + frames under one roof

Most bike shops laser little tabs, yokes, and gussets from sheet too. A combo platform covers both with one controller. Look at Laser Plate & Tube Combo Fiber Laer Cutting Machine.

Compact footprint for studio builders

Tight shop? A smaller table still eats 90% of bike parts just fine. The Máquina de corte a laser de fibra 5050 is a neat fit.

Process setup that saves your hours

CAM & modeling

Design joints with tabs/slots where it helps assembly. Keep slot clearance practical, not tight-tight. Add small lead-ins so the cut starts clean, away from the show face.

Fixturing smart, not heavy

Simple V-blocks or 3D-printed nests get you repeatable zero.

Parameter sanity

Don’t chase speed only. Target stable pierce, proper focus position, straight kerf. If edge looks melty, you’re too hot or too slow. If dross sticks, bump assist gas or clean the nozzle. Easy words, but yes—takes a few runs to dial. No big deal.

Quality loop

Dry-fit, measure angles with a quick gauge, tack, then weld. If a joint keeps gapping, check tube ovality and CAM compensation. Sometimes the tube isn’t round; the laser didn’t “miss,” it followed your geometry. We adjust, it behaves.

A simple framework to justify the buy

| Cost bucket | Old way | Tube-laser way | What really changes |

|---|---|---|---|

| Prep & fit | Saw + drill + file + jig | One-pass cut with bevel & holes | Fewer hand ops; fit-up gets predictable |

| Fixtures | Big custom jigs | Tab-and-slot, light fixtures | Less design/build time; faster changeover |

| Rework | Grind, re-cut, swear | Consistent edges & angles | First-pass yield climbs; welder less grumpy |

| Taxa de transferência | Stop-start | Stable cycle | You ship on time more often |

You can run the same before/after logic on a small shop or a volume OEM. The shape of the graph changes, the direction doesn’t.

Materials and welding: keeping it clean

Stainless: Low heat input cuts keep colors light; still back-purge for inside cleanliness.

Alumínio: Watch burrs and edge smear; good nozzle alignment and fresh gas help.

Titânio: Keep everything clean-clean; prepare for post-cut handling with gloves. Edge quality from laser saves you from heavy bevel grinding.

Common questions (and quick answers)

Can I ditch jigs completely?

Not always. But tabs/slots + simple locators will erase a lot of heavy fixturing. You’ll feel it in changeover time.

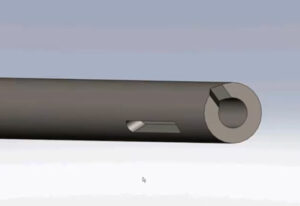

Do I need 5-axis everything?

If bevelled mitres are daily bread, yes, go for bevel capability. If you only square-cut stays and drill later, a simpler head might do. Right tool, right purpose.

What about cut color and HAZ?

Tune parameters; use clean assist gas; keep focus true. You’ll see clean edges that weld fine. No need to invent a number to prove it.

Tiny batches—worth it or no?

Yes. The real win is fewer setups and fewer mistakes. Prototypes stop breaking your schedule.

Where BOGONG Laser fits in

BOGONG LASER is a Laser Cutting Machine Manufacturer and Laser Cutting Machine Factory with a full line—cutting, marking, cleaning, welding—plus OEM/ODM. We keep things practical: CE, ISO9001, SGS, FDA, and France BV certifications give your QA team less to worry about; our multilingual team makes specing and support not painful. If you need a tube laser tuned for bicycle components—bevel cuts, tab-and-slot, routing ports—we’ll spec the head, software, and handling so your shop can actually run it day one.

Conclusão

A customized tube Máquina de corte a laser cuts bevels, mitres, and routing holes in one pass, so parts drop in and weld steady. Tabs-and-slots guide the fit, so alignment feels natural and rework stays low. Keep the recipe simple: model smart, set clean lead-ins, dry-fit, tack, then weld.

If you’re interested in working with BOGONG, please fill out the contact BOGONG form below.