-

Strada Shunhua, città di Jinan, Shandong

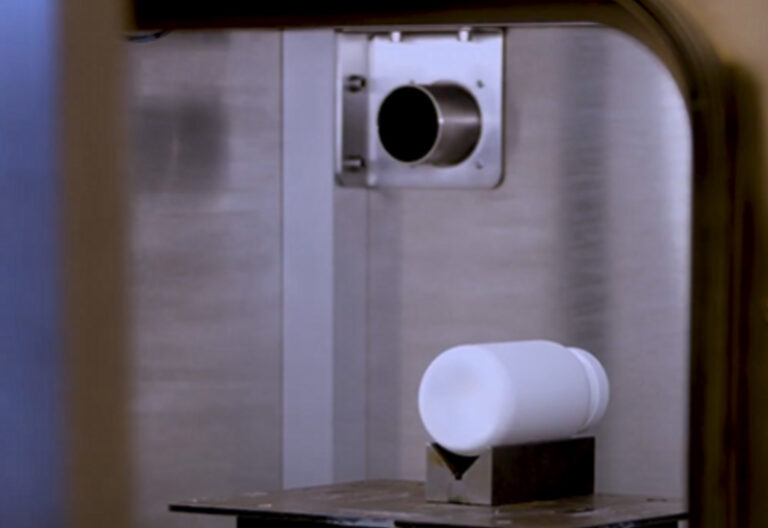

Macchina marcatrice laser UV per uova

La macchina marcatrice laser UV per uova di BOGONG offre una codifica pulita e senza inchiostro. Aumentate l'igiene, la tracciabilità e la fiducia nel marchio con soluzioni tecnologiche laser certificate.

Le uova sono fragili, in rapido movimento e di qualità alimentare. Marcarle senza che si rompano o si contaminino non è un'impresa da poco. È qui che il Macchina marcatrice laser UV entra in scena. Scopriamo cos'è, come funziona e perché l'industria delle uova lo sta adottando.

Che cos'è una macchina per marcatura laser UV?

A Macchina marcatrice laser UV è uno strumento di precisione che utilizza un raggio laser ultravioletto da 355 nm per incidere segni permanenti su materiali sensibili come gusci d'uovo, plastica, ceramica e altro. A differenza dei laser a fibra o a CO₂, i laser UV utilizzano un fascio di raggi ultravioletti. "marcatura a freddo" che si traduce in un calore minimo e in zero danni alla superficie.

Queste macchine sono progettate per i settori che necessitano di una codifica ad alta risoluzione e senza contatto, dove pulizia e chiarezza sono importanti. Pensate ai dispositivi medici, all'elettronica... e ora, imballaggio alimentare.

Come funziona la marcatura laser UV sulle uova?

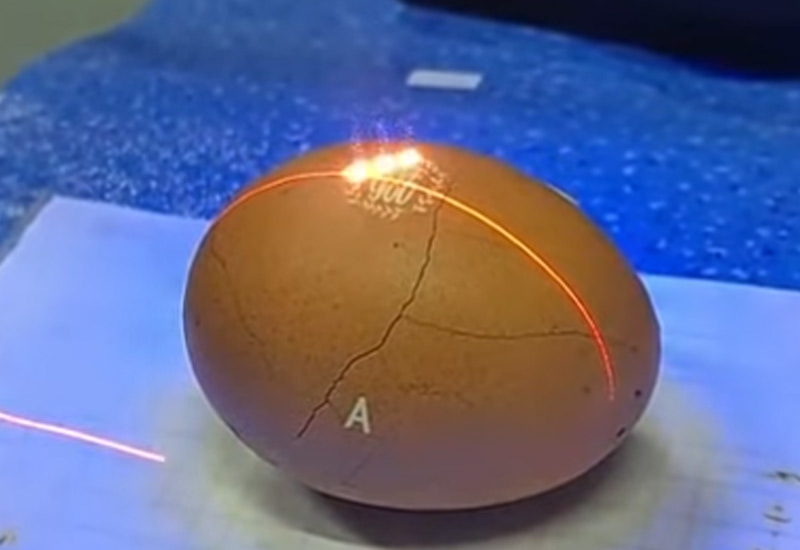

Il processo è sorprendentemente semplice ma estremamente preciso.

Quando un laser UV colpisce il guscio d'uovo, rompe lo strato superficiale a livello microscopico, senza incrinarlo. Poiché il fascio laser è ultra-fine e non termico, segna testo, loghi o codici puliti senza pressione, calore o inchiostro.

Ecco come funziona passo dopo passo:

Sistema di scansione punta ogni uovo sul nastro trasportatore

Laser UV impulsi ad alta frequenza (decine di migliaia al secondo)

Testa di marcatura scrive direttamente sul guscio: codice QR, data o codice azienda

Il sistema passa all'uovo successivo.funzionamento nonstop

Questo metodo "senza contatto" significa che non c'è trasferimento di inchiostro, non c'è rischio di contaminazione e non ci sono tempi morti per la pulizia.

Perché utilizzare la marcatura laser UV sulle uova?

Sistemi tradizionali a getto d'inchiostro? Disordinati. Pesanti dal punto di vista chimico. Alta manutenzione.

Laser UV? Pulito. Veloce. Sostenibile.

Analizziamo i principali vantaggi:

1. Guscio fragile? Nessun problema

I laser UV marcano senza pressione o accumulo di calore

Il guscio rimane intatto, senza microfratture e senza uova rotte.

2. Igiene e sicurezza alimentare

Niente inchiostro = niente sostanze chimiche

Pienamente conforme alle norme di sicurezza alimentare FDA/CE

Nessun rischio di contaminazione incrociata durante le corse ad alta velocità

3. Bassa manutenzione

Le stampanti a getto d'inchiostro si intasano e si rompono

I sistemi UV funzionano per migliaia di ore con una manutenzione minima.

Nessuna ricarica di inchiostro o ugelli sporchi

Confronto rapido delle funzioni

| Caratteristica | Stampante a getto d'inchiostro | Macchina marcatrice laser UV |

|---|---|---|

| Materiali di consumo | Inchiostro, solvente | Nessuno |

| Igiene | Medio (uso di sostanze chimiche) | Alto (senza contatto, pulito) |

| Compatibilità della superficie | Limitato | Ideale per superfici curve e fragili |

| Costo nel tempo | Alto (inchiostro, manutenzione) | Basso (solo manutenzione) |

| Marchio di qualità | Sbiadisce, si macchia | Permanente, ad alta risoluzione |

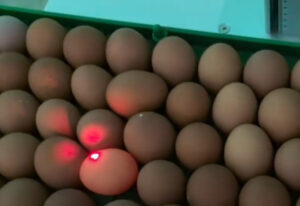

Casi d'uso reali del settore delle uova

Ora, dove viene utilizzato?

In tutti gli allevamenti di uova, gli impianti di lavorazione e le fabbriche di confezionamento, i sistemi laser UV stanno sostituendo le vecchie stampanti. Che si tratti di una piccola azienda biologica o di un distributore globale, le ragioni sono le stesse: tracciabilità, igiene e velocità.

Scenari di applicazione

| Ruolo nel settore | Uso del laser UV | Vantaggi |

|---|---|---|

| Produttori di uova | Marchio di origine, scadenza, stato biologico | Fiducia nel marchio, tracciabilità |

| Linee di imballaggio | Codice sullo spostamento delle uova tramite automazione | Velocità + qualità costante |

| Fattorie da esportazione | Etichettatura multilingue | Soddisfa le norme di importazione |

| Fornitori al dettaglio | Aggiungere codici QR per informazioni sui consumatori | Trasparenza + conformità |

I sistemi BOGONG LASER si integrano senza problemi in linee di trasporto, sistemi di alimentazione automatica e bracci robotici. Il nostro Macchina per la marcatura laser UV 3D anche le superfici irregolari come le uova di anatra o di quaglia.

Perché scegliere BOGONG LASER?

BOGONG non è solo un altro Macchina marcatrice laser UV fabbrica. Abbiamo spedito in oltre 160 paesi, servito più di 9.000 clienti e gestito più di 400 progetti di integrazione laser in diversi settori, dalla gioielleria all'agricoltura.

Quando si tratta di marcatura per uso alimentare, forniamo:

Certificazioni complete CE, FDA, ISO9001, SGS

Costruzioni personalizzate OEM/ODM

Assistenza rapida e formazione a distanza

Affidabilità comprovata in linee di produzione 24/7

Se siete alla ricerca di un Cina Macchina di marcatura laser UV produttore che si occupa sia di tecnologia che di sicurezza alimentare: ci avete appena trovato.

Conclusione

Nel settore delle uova, l'accuratezza è importante. I consumatori vogliono sapere da dove proviene il loro cibo. I governi chiedono la tracciabilità.

Una macchina per la marcatura laser UV consente di ottenere codici permanenti e ad alta risoluzione senza sprechi, senza inchiostro e senza congetture. Che si tratti di codici di data, etichette di origine o tag QR, questa macchina mantiene intatte le vostre uova e la vostra reputazione.

Siete pronti a rendere la vostra linea di produzione di uova a prova di futuro?

Lasciate che LASER BOGONG aiutarvi a spalancare la porta.