-

Strada Shunhua, città di Jinan, Shandong

Purchase of Automobile Body Frame Laser Welding Machine

Laser welding machines for automotive body frames: improve strength, precision & speed. Discover BOGONG's pro-grade systems built for real production needs.

Purchasing an automobile body frame laser welding machine involves considering budget, functional capabilities, and future-proofing for evolving vehicle materials and repair needs.

Why Auto Makers Are Ditching Traditional Welding

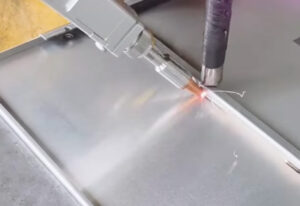

As car bodies get lighter, stronger, and more complex, old-school MIG and TIG methods just can’t keep up. You’ve got heat distortion, messy seams, low precision, and way too much post-processing. That’s where a modern Macchina per saldatura laser comes in.

If you’re building or repairing automobile body frames, you already know the pressure—tight deadlines, tough materials, and zero tolerance for visible weld marks. Laser welding solves a lot of that pain with cleaner joints, faster output, and smoother automation.

From Sheet Metal to Full Body Frame—Laser’s Taking Over

Laser welding is critical. And here’s why it’s blowing up in the body frame industry:

| Automotive Challenge | Laser Welding Advantage |

|---|---|

| Thin high-strength steel | Low heat input = less warping |

| Tight manufacturing tolerance | Spot-on precision with fiber lasers |

| High production demand | High-speed automation-ready systems |

| Clean finish required | Minimal splatter, no grinding needed |

| Difficult-to-reach corners | Handheld and robotic nozzles go anywhere |

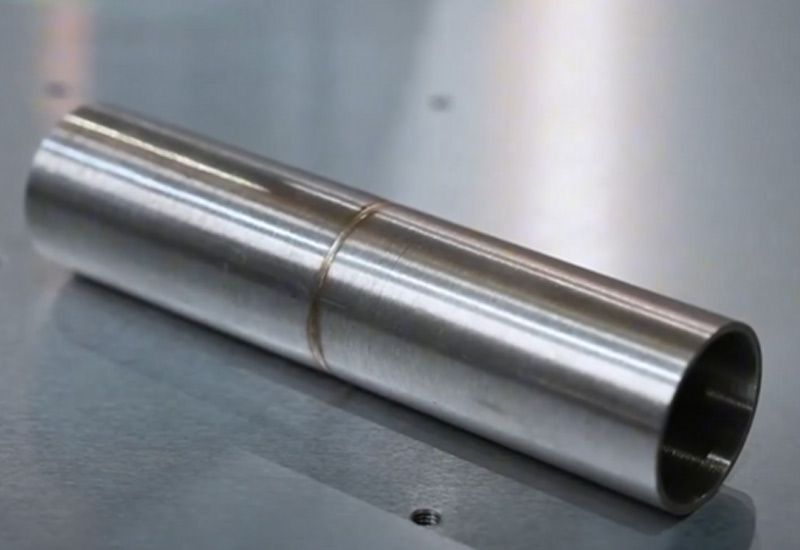

In body frame production—think rocker panels, pillars, and roof frames—laser welds are now often stronger than the base metal. You’re not melting metal. You’re microscopically fusing it.

Common Welding Problems Laser Fixes Instantly

Warping around door frames? That’s heat creep from arc welding.

Spatter clean-up eating into your man-hours? Laser gives you spotless seams.

Rework due to poor penetration? Fiber lasers control depth like a scalpel.

We’re talking major efficiency wins. Teams using laser welding for automotive frames have cut rework rates drastically. And for anyone doing spot or continuous seam welds, it’s a night-and-day upgrade.

Where It Works Best in Auto Body Repair & Manufacturing

Some use cases:

Door panels and crash beams—complex contours, zero heat distortion

Roof and floor reinforcements—long seams with clean aesthetics

Aluminum structures—fiber laser nails it without filler wire

- Tailored blanks—variable thickness? No problem

It even works wonders on high-tensile materials where traditional welding would crack or weaken the metal.

Laser vs Arc Welding: No Contest for Body Frames

You’re probably wondering: how much better is laser compared to TIG/MIG for body frames?

| Caratteristica | MIG/TIG Welding | Saldatura laser |

|---|---|---|

| Heat input | Alto | Very low |

| Deformation risk | Medium to high | Extremely low |

| Aesthetic finish | Requires grinding | Clean, mirror-like finish |

| Automazione | Limitato | Full robotic integration |

| Material support | Basic metals | Steel, aluminum, alloys |

| Weld speed | Lento | Veloce |

Laser welding eats arc welding for breakfast when it comes to precision and repeatability. And if you’re trying to meet stricter safety and aesthetic standards—especially for EVs—laser wins every time.

How to Choose the Right Machine for Auto Body Work

Not all laser welding machines are built for auto-grade tasks. Some key things to look for:

High-stability fiber source—less maintenance, tighter control

Portable handheld units for flexible repair zones

Seam tracking and CCD cameras for fine control on thin sheet

Compatibility with auto robotics for frame lines

For instance, if you’re handling trim-level welds or tight-access jobs, a Saldatrice laser portatile gives you mobility with serious power.

If your team needs flexibility across multiple joints and angles, check out the Saldatore laser portatile 3 in 1. It fuses cutting, cleaning, and welding in one go—ideal for rapid cycle shops or mobile repair units.

Use Cases: What the Industry’s Doing Right Now

Around the globe, manufacturers are using laser welding to speed up frame builds without losing strength. Here’s what’s happening on the ground:

Modular EV platforms now rely on laser-welded tailored blanks to minimize weight and maximize crash performance.

OEM part suppliers are switching to compact systems like the Macchina per saldatura laser portatile con raffreddamento ad aria to keep small repair stations lean and efficient.

Custom car fabricators are replacing arc welders with Handheld Laser Welder Welding Machines to get smoother, more visible seams on exposed body parts.

What Makes BOGONG Laser a Smart Partner?

BOGONG Laser isn’t just a Saldatrice laser Produttore—we’re in 160+ countries with over 9,000 clients and counting. Our Fabbrica di macchine per la saldatura laser produces CE, ISO9001, SGS, and FDA-certified machines that are OEM/ODM-ready. You get:

Global tech support that speaks your language

Custom configurations for automotive lines

Fast delivery and full documentation

Real integration advice—because no two body shops are the same

Summing it up

If you’re in auto body frame production or repair, laser isn’t a luxury anymore—it’s the standard. Lower downtime. Stronger welds. Clean aesthetics. Laser gets you ahead, especially when paired with scalable automation or mobile repair setups.

BOGONG Laser makes the transition simple. Whether you’re a large OEM or a lean custom shop, we’ve got a solution that fits.

Fill out our contact form and let’s talk. We’ll help you choose the best fit based on your materials, workspace, and production flow.