-

Strada Shunhua, città di Jinan, Shandong

Laser Engraving Solutions for Medical Device Marking

Meet FDA UDI standards with durable, precision laser engraving for medical devices. Fiber, UV, CO₂ systems from BOGONG Laser boost efficiency and traceability.

The Rise of Laser Engraving in Medical Device Marking

From Ink to Laser: A Marking Evolution

Wet-ink printers and chemical etching came with headaches: fading codes, solvent exposure, constant consumables. Laser-etched marks become part of the substrate. You get ultra-fine lines, no consumables, and low maintenance.

Why You Can’t Ignore UDI Compliance

The FDA’s Unique Device Identification (UDI) rule demands permanent, legible codes on most devices by now. Non-compliance can trigger hefty fines or worse—product holds. With laser engraving, you can produce high-contrast UDI codes that survive acid baths, gamma radiation, and thousands of steam cycles.

Core Advantages of Laser Engraving Solutions for Medical Devices

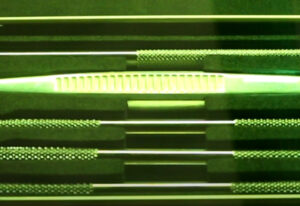

Precision & Durability

Extremely fine line widths let you pack more data into tight spaces—think Data Matrix codes on micro hardware. The result stands up to handling, shipping, and cleaning without fading.

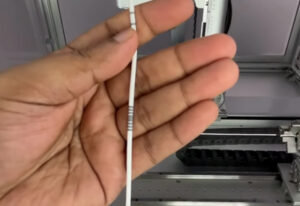

Non-Contact Versatility

Because nothing touches the part, you avoid micro-abrasions and protect coatings. That’s essential for sensor housings or polymer catheters where smooth surfaces matter.

Velocità e produttività

Modern laser sources deliver rapid marking with quick recipe changes. Switching from stainless forceps to polymer hubs is seamless, so takt time stays tight.

Matching Laser Type to Material and Use

| Tipo di laser | Material Scenario | Relative Speed | Typical Use-Case |

|---|---|---|---|

| Fiber (MOPA) | Stainless steel, titanium | Veloce | UDI codes on implants and surgical tools |

| UV | Polymers, glass | Moderato | Catheter tubing, electrical connectors |

| CO₂ | Ceramics, composites | Moderate-fast | Labware, instrument housings |

| 3D Fiber Engraving | Curved metal surfaces | Veloce | Plates, housings, complex geometries |

BOGONG Laser Line-Up for Medical Marking

Macchine per la marcatura laser in fibra

When you need robust, permanent marks on metals, BOGONG’s Macchina di marcatura laser a fibra 30W shines. It uses MOPA technology for annealed marks that resist corrosion, essential for orthopedic implants.

Key Benefits: Sub-micron precision; auto-focus for curved tools; low running costs.

Actual situation: Engraving on the stethoscope’s listening head—the chestpiece (diaphragm/bell). The system produces clean, high-contrast annealed marks on the metal ring or housing with no burrs or surface roughening, and the marks withstand hospital disinfectants and repeated sterilization.

Macchina di marcatura laser all-in-one

If you want plug-and-play compliance, the Macchina di marcatura laser in fibra all-in-one bundles a laser head, vision sensor, and touchscreen HMI in a neat cell.

Key Benefits: Integrated mark-and-read; batch-link software; auto-report generation.

Actual situation: A surgical tool shop slashed audit prep from days to hours, using its built-in IQ/OQ/PQ validation protocols.

UV Laser Marking Systems

For polymers and delicate electronics, check out the UV Laser Marking Machine / UV Laser Engraver, high-contrast marks with a minimal heat-affected zone.

Highlights: clean results on plastics, excellent edge definition, gentle on sensitive

In practice: a catheter line lifted throughput after replacing chemical etching—no more stoppages for acid handling.

CO₂ Laser Marking Units

For ceramics and some composites, BOGONG’s Macchina per la marcatura laser CO₂ delivers crisp white marks that stand out on dark substrates.

Key Benefits: High absorption on glass and ceramics; uniform depth; low maintenance.

Use Case: A labware OEM switched from sandblasting to CO₂ marking, cutting cleaning-validation steps in half.

3D Fiber Laser Engraver for Metal

Need to tackle curved or irregular surfaces? The Incisore laser a fibra 3D per metallo uses multi-axis motion for consistent engraving across complex geometries.

Key Benefits: True 3D path control; recipe library for dozens of device types; remote monitoring.

Customer Story: An endoscope component maker doubled output—no more manual fixturing—to hit 120 pcs/hour.

Case Studies in Device Marking

Enhancing Spinal Implant Traceability

A device OEM needed tiny, permanent codes on compact screw heads. A fiber system delivered crisp Data Matrix marks that passed relevant ISO audits without non-conformances.

Speeding Up Surgical Tool Production

A scissors workshop hit limits with chemical etching. After installing the all-in-one fiber cell, cycle time dropped substantially and ventilation demands eased—no acid handling, fewer interruptions.

Choosing Your Laser Engraving Machines Factory & Manufacturer

Factory-Direct Partnership

When you deal direct with a Laser Engraving Machines Factory like BOGONG Laser, you skip middle-man markups and get faster R&D feedback.

Certifications & Global Support

BOGONG Laser carries CE, FDA, ISO 9001, SGS, and France BV certifications. With over 9,000 systems in 160+ countries, you get multilingual manuals, 24/7 tech support, and pre-installation IQ/OQ/PQ kits.

Conclusione

Switching to laser engraving for medical device marking isn’t just about clean codes—it’s about protecting patients, clearing audits, and keeping production flowing. Whether you need fiber for metals, UV for polymers, or an all-in-one mark-and-read cell, BOGONG Laser can match your materials, workflow, and compliance needs. Ready to tighten traceability and simplify validation? Let’s talk.