-

Strada Shunhua, città di Jinan, Shandong

Macchine da taglio laser per prodotti in acrilico e plastica

BOGONG Laser offre macchine di taglio laser di altissimo livello per acrilico e plastica, aumentando la precisione, la produttività e il ROI della vostra fabbrica. OEM/ODM, CE E ISO9001.

Finitura lucidata a fiamma con minimi ritocchi

Avete mai preso un'insegna in acrilico e vi siete chiesti come abbia fatto a ottenere quei bordi lucidi e senza scheggiature? Questa è la magia del laser. Un buon Tagliatrice laser per acrilico offre un taglio lucidato alla fiamma che non richiede quasi nessuna levigatura o lucidatura successiva. In questo modo si evita il lavoro di post-elaborazione e si possono consegnare più lavori alla porta.

Per esempio, un negozio di insegne di medie dimensioni è passato dal taglio con la fresa a una CO₂ Taglierina laser. I tempi di finitura sono stati ridotti di 70%, senza più polvere di levigatura che riempiva l'aria. Questo ha permesso loro di partecipare a gare d'appalto per lavori con tempi di esecuzione più rapidi, senza aggiungere personale.

Un consiglio da professionista: Cercare una qualità del fascio migliore di M²=1,1. Ciò significa un punto più stretto e un taglio più regolare. I numeri M² più bassi si traducono in una minore pulizia e in angoli più netti, un fattore critico quando si devono tagliare lettere in acrilico fuso da 3 mm per un cliente di fascia alta.

Macchina da taglio laser per acrilico: Bordi cristallini

Tagliatrice laser per plastica: precisione inferiore a 0,1 mm

Precisione costante nei tagli complessi

Quando si tagliano forme intricate - si pensi alle staffe per pannelli a nido d'ape o alle griglie di ventilazione per l'elettronica - la precisione è irrinunciabile. Moderno Macchine per il taglio laser della plastica tolleranze inferiori a 0,1 mm. È un valore sufficiente per i componenti a incastro e per gli involucri a tolleranza ristretta.

Prendiamo un piccolo produttore di elettronica che aveva bisogno di pannelli in policarbonato con distanziatori incorporati. Hanno provato una configurazione laser in fibra di un'azienda locale. Macchina da taglio laser Fornitore. La ripetibilità era così stretta che la loro linea di assemblaggio ha smesso di scartare i pezzi per disallineamento. La produzione è aumentata di 30%, semplicemente perché ogni taglio era perfetto.

| Spessore del materiale | Potenza (W) | Velocità (mm/s) | PPI (per CO₂) |

|---|---|---|---|

| Acrilico 3 mm | 100 W | 2 mm/s | 500 |

| 5 mm PETG | 120 W | 1,5 mm/s | 600 |

| Policarbonato da 2 mm | 80 W | 3 mm/s | 450 |

Le impostazioni sopra riportate sono indicative. Effettuare sempre un taglio di prova per regolare la messa a fuoco del fascio e la densità del nido.

Produttore di macchine per il taglio laser: Gamma versatile di scenari

Dalla segnaletica ai componenti elettronici

Una delle più grandi flessioni di un prodotto di alto livello Fabbrica di macchine per il taglio laser è il numero di scenari che può gestire. Non ci si limita alle lamiere piatte, ma si parla di taglio di tubi, smussatura e persino di attrezzature combinate per lamiere e tubi.

Segnaletica e premi: Bordi puliti su trofei in acrilico, in-gradienti e costruzioni a strati.

Modelli architettonici: Tagli di precisione su plastiche sottili per i costruttori di modelli in scala.

Alloggiamenti per elettronica: Staffe scanalate, schemi di ventilazione e distanziatori nei PCB.

Artigianato e hobby: Stencil personalizzati per gioielli, pannelli per light-box, finiture decorative.

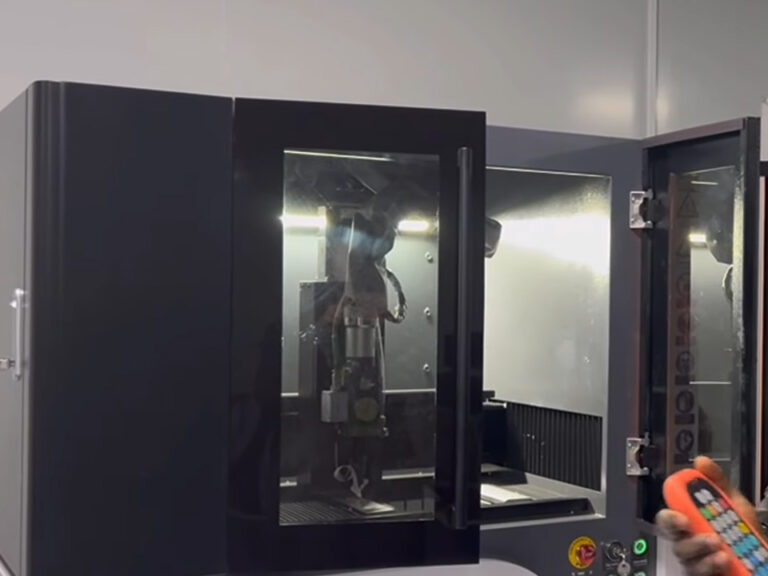

Caratteristiche di sicurezza delle macchine per il taglio laser

Gestione dei processi e dei fumi senza contatto

La sicurezza non è solo una casella di controllo: è un fattore di produttività. Il taglio senza contatto significa che non ci sono morsetti che rovinano le plastiche delicate. Inoltre, riduce i problemi di usura degli utensili che si possono verificare con una fresatrice. Cosa rimane? Un percorso ottico sigillato e un buon sistema di ventilazione per eliminare i vapori acrilici.

Cercate caratteristiche come:

Area di lavoro chiusa con interblocchi.

Filtri per fumi di grado HEPA o scrubber esterni.

Teste di messa a fuoco automatica che impediscono di regolare manualmente l'altezza (e di rompere gli ugelli!).

In un'officina, un team è passato da una taglierina CO₂ a letto aperto a un sistema Fiber chiuso. In un anno hanno riportato zero incidenti alla vista e hanno ridotto i tempi di inattività di 25%, poiché non dovevano riallineare gli specchi dopo ogni turno.

Sono un blocco di testo. Fare clic sul pulsante di modifica per cambiare il testo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

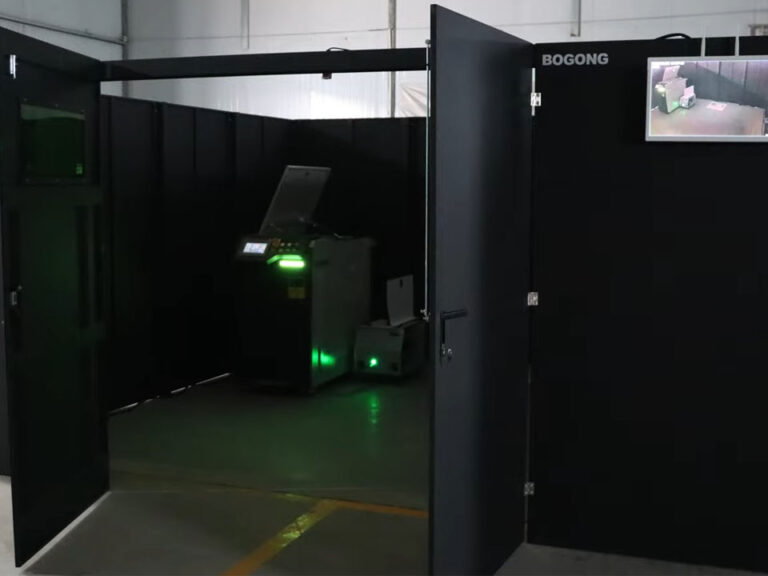

Perché il laser BOGONG è leader nel settore

Noi di BOGONG Laser conosciamo i punti dolenti: ritardi di produzione, budget per gli scarti, timori per la sicurezza, e costruiamo macchine che rispondono a queste esigenze. Il nostro Fabbrica di macchine per il taglio laser in Cina produce impianti a CO₂ e a fibra, tutti certificati CE, ISO9001, SGS e FDA. È possibile ottenere la flessibilità OEM/ODM per modificare le ottiche, gli algoritmi di nesting e persino le dimensioni del letto.

Il vantaggio del mondo reale: Oltre 9.000 clienti in più di 160 paesi si affidano a noi per gestire qualsiasi cosa, dalla pulizia dalla muffa alla decorazione in acrilico da 3 mm. Abbiamo anche aggiunto il supporto multilingue all'interfaccia utente del nostro controller, in modo che i vostri operatori si sentano a casa, senza gergo inglese.

Scopri l'elenco completo Categoria macchine per il taglio laser per le specifiche e i casi di studio.

Vedi il nostro Macchina per il taglio laser in fibra per ottone, argento e altro ancora.

Focus B2B e certificazioni

Il BOGONG Laser® non è solo un altro Macchina da taglio laser Fornitore-Siamo certificati CE, ISO9001, SGS e FDA, per cui sapete di ottenere sempre un'affidabilità di livello industriale. Inoltre, l'interfaccia utente del nostro controller supporta più lingue, in modo che il vostro team si attivi più rapidamente, indipendentemente da dove vi troviate.

Ottica personalizzata OEM/ODM e software di nesting

Avete bisogno di una lente focale speciale per l'acrilico ultrasottile o di un tavolo di dimensioni personalizzate? Realizziamo internamente le modifiche OEM/ODM. Il nostro algoritmo di nesting consente di ottenere più pezzi per foglio, riducendo gli sprechi di materiale e i tempi di esecuzione.

ConclusioneSe avete bisogno di una soluzione ad alta precisione, a basso spreco, sicura e versatile, una macchina da taglio laser BOGONG per acrilico o plastica è quello che fa per voi. Sia che si tratti di un piccolo laboratorio artigianale o di una linea di produzione ad alto numero di pezzi, queste macchine offrono la qualità di finitura, l'accuratezza e i tempi di attività che desiderate, senza spendere troppo in materiali di consumo o manutenzione.