-

Strada Shunhua, città di Jinan, Shandong

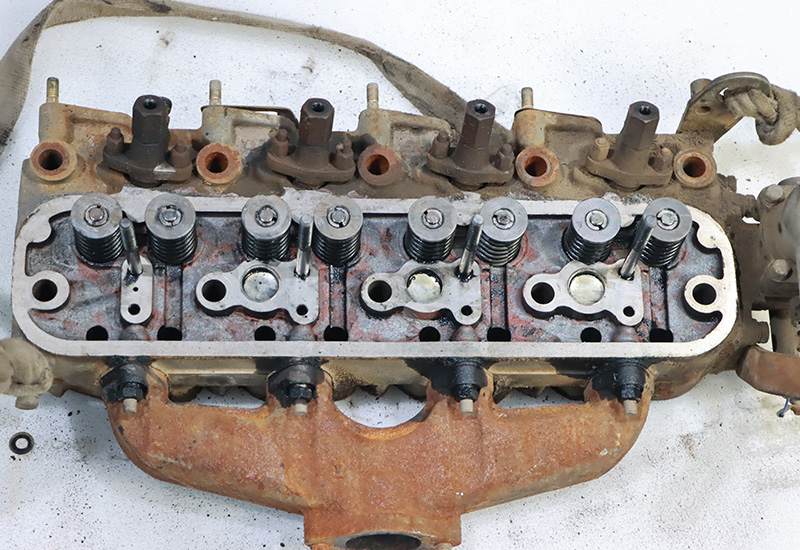

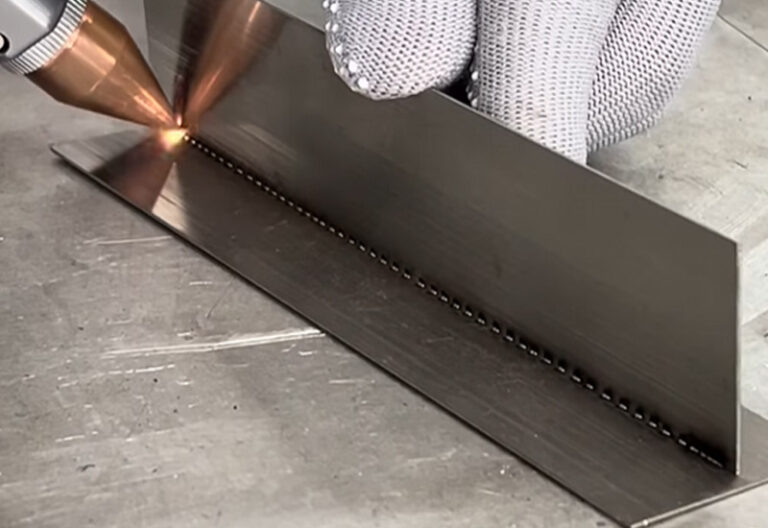

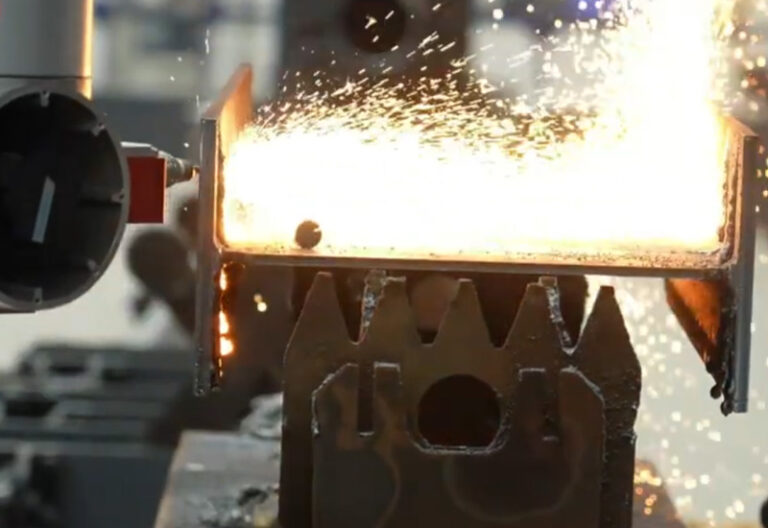

Applicazione della macchina di pulizia laser

Applicazione della macchina di pulizia laser

Dal 2009, le nostre macchine per la pulizia laser sono state esportate in oltre 180 Paesi, servendo più di 9.000 clienti. Le nostre apparecchiature possiedono le certificazioni CE, FDA, ISO9001 e SGS, a garanzia della massima qualità e sicurezza. La tecnologia di pulizia di Bogong Laser offre una pulizia ecologica, senza contatto, senza sostanze chimiche e con scarti minimi, aiutando le industrie a migliorare l'efficienza e la qualità della preparazione delle superfici.

Panoramica delle categorie di applicazione delle macchine per la pulizia laser

Raccomandazione sui prodotti per la pulizia laser

Macchine per la pulizia con laser pulsato: Impulsi ad alta energia per lavori di pulizia intensivi come la rimozione di ruggine e vernice.

Macchine per la pulizia laser a onda continua (CW): Ideale per la pulizia di superfici delicate e la rimozione di residui fini.

Tutti i modelli offrono un controllo preciso, bassi costi operativi e una pulizia ecologica senza scarti secondari.

Migliore macchina per la pulizia del laser a impulsi da 300W

Macchina per la pulizia del laser CW

Macchina di pulizia laser a impulsi 1000W

Macchina di pulizia laser di tipo trolley

Migliore macchina per la pulizia del laser a impulsi da 200W

Macchina di pulizia laser a impulsi da 500W

Macchina di pulizia laser a impulsi con laser Raycus Max JPT

Domande frequenti sulle macchine per la pulizia laser

Contattateci per aiutarvi a scegliere la macchina di pulizia laser più adatta a voi:

Blog di BOGONG LASER® - Applicazione della macchina di pulizia laser e informazioni sull'industria

CO2 Laser Cutting Machine for Foam Tool Inserts

CO2 laser cutting for foam tool inserts: improve tool control, reduce waste, and upgrade your workshop look with BOGONG Laser CNC solutions for global industrial users.

Handheld Laser Welder for Display Sign Frames

Handheld Laser Welding Machine for display sign frames: cut grinding, reduce distortion and boost finish quality with BOGONG LASER® welding solutions for signage.

Laser Metal Cutting Machine for Construction Formwork

Laser Metal Cutting Machine for construction formwork. Cut cleaner panels, reduce scrap, speed delivery. BOGONG LASER helps factories upgrade cutting for real site demands.

Fiber Laser Cutting Machine for Kitchen Exhaust Hoods

Fiber Laser Cutting Machine for kitchen exhaust hoods: improve cut quality, airflow parts and lead time with BOGONG LASER, a global laser cutting machine manufacturer.

Fiber Laser Marking Machine for Bearing Batch Codes

Fiber laser marking for bearing batch codes. Learn how BOGONG Laser machines boost traceability, fight counterfeits and cut rework for global bearing makers.

Laser Engraving Machine for Tumbler Customization

Looking for stable tumbler branding? Discover how BOGONG Laser Engraving Machine solutions help factories customize cups in-house and grow B2B orders.