-

Strada Shunhua, città di Jinan, Shandong

Taglio laser in fibra di opere d'arte e insegne metalliche personalizzate

Scoprite come il taglio laser in fibra aumenta la precisione, la velocità e il ROI per le opere d'arte e le insegne metalliche personalizzate: casi di studio reali e soluzioni BOGONG Laser.

Nel mondo della metal-fabbrica di oggi, macchine per il taglio laser in fibra vi offrono tagli affilati come rasoi, velocità di taglio impressionanti e la flessibilità necessaria per realizzare progetti che i tecnici più vecchi non possono affrontare. Sia che stiate realizzando lavori da parete pronti per la galleria o insegne per negozi di grande impatto, un laser a fibra trasforma lastre piatte in pochi minuti in oggetti che attirano l'attenzione. Esamineremo cinque punti fondamentali: precisione, produttività, libertà di progettazione, portata dei materiali e convenienza economica, con il supporto di dati reali, casi di studio e Laser BOGONGe i test condotti da noi stessi. Vedrete come questi cavalli di battaglia del CNC affrontano punti dolenti come l'accumulo di scorie, le zone colpite dal calore e le lunghe configurazioni, il tutto incrementando i vostri profitti.

Precisione con il taglio laser a fibra nelle opere d'arte in metallo

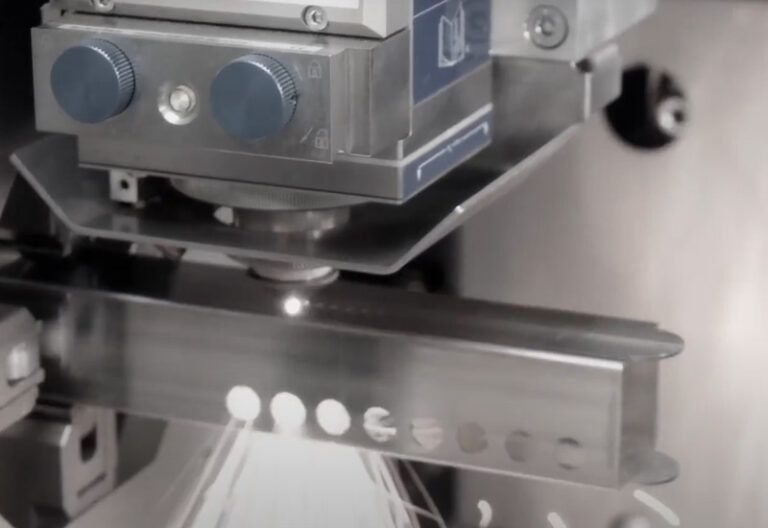

Quando servono dettagli di livello micro - testi sottili, filigrane o sovrapposizioni simili a pizzi - i laser in fibra consentono di ottenere tolleranze fino a ±0,1 mm. Il taglio ultra-sottile (spesso inferiore a 0,2 mm) mantiene i bordi nitidi ed evita l'aspetto ingombrante e ruvido dei tagli a ossitaglio o a CO₂. Nelle prove in officina, il sistema BOGONG 5050 Macchina per il taglio laser a fibra inchiodati motivi floreali in acciaio inox da 1 mm in meno di 2 minuti ciascuno, pronti per il montaggio senza alcuna rifinitura manuale. Modificando il ritardo di foratura e le strategie di nesting nel software CAM, è possibile ridurre le scorie e le microsaldature, riducendo i tempi di pulizia fino a 30%.

For high‑contrast gallery pieces, less heat‑affected zone (HAZ) means no discoloration or warping. With beam powers up to 500 W focused through a nano‑head, you carve swirl patterns into backlit panels without compromise. And if you’re doing silver or gold jewelry blanks, check this 1000 W demo—no extra tooling, just drop in your file and watch pins and bezels come out flawless:[/vc_column_text][vc_column_text css=””]

Tagliatrice del laser della fibra 1000W per il taglio dei gioielli dell'argento dell'oro | Taglierina del laser della fibra 1000W di BOGONG

Velocità e produttività del taglio laser in fibra per la segnaletica

Le scadenze strette si incontrano con la fibra. Un sistema a CO₂ da 5 kW può funzionare in modo inossidabile a 2 m/min, ma un laser a fibra da 2 kW fa saltare la stessa lastra da 2 mm a 6 m/min, triplicando la produzione (rapporto Accurl). Ecco un rapido confronto:

| Tipo di macchina | Potenza | Materiale | Spessore | Velocità (m/min) |

|---|---|---|---|---|

| CO₂ Laser | 5 kW | Acciaio inox | 2 mm | 2.0 |

| Laser a fibra | 2 kW | Acciaio inox | 2 mm | 6.0 |

| Laser a fibra | 6 kW | Acciaio dolce | 6 mm | 2.5 |

In un negozio di insegne che produce pannelli di 20 × 30 cm, questo salto di velocità riduce il tempo di lavorazione da 30 minuti a soli 10 minuti. Aggiungete il 6000W-40KW macchina di taglio laser a fibra e sarete pronti a lavorare su grandi volumi di acciaio dolce fino a 25 mm. Abbinatela al Tagliatrice automatica del tubo del laser di caricamento e la vostra officina lavora giorno e notte, autoalimentando lamiere e tubi senza l'intervento di un operatore.

Versatilità del materiale in tutti gli scenari

I laser a fibra non fanno preferenze. Pannelli in acciaio inox, acciaio dolce, alluminio, ottone e persino zincati vengono tagliati con tolleranze costanti. Consultate la scheda tecnica di BOGONG:

| Materiale | Spessore massimo (mm) | Velocità (m/min) | Tolleranza (mm) |

|---|---|---|---|

| Acciaio inox | 16 | 3.5 | ±0.1 |

| Acciaio dolce | 25 | 6.0 | ±0.15 |

| Alluminio | 10 | 4.0 | ±0.1 |

| Ottone / Rame | 6 | 2.0 | ±0.12 |

Questo mix apre le porte ai gioiellieri che un giorno tagliano pezzi intricati e il giorno dopo targhe automobilistiche. Se vi destreggiate tra telai tubolari e pannelli piatti, la macchina combinata in grado di Tagliatrice automatica del tubo del laser di caricamento cambia modalità in pochi secondi: nessun riallineamento, nessun problema. Per i piccoli lotti di produzione artigianale, il compatto 3020 Macchina per il taglio laser a fibra si adatta perfettamente a qualsiasi studio, pur mantenendo la stessa precisione di ±0,1 mm.

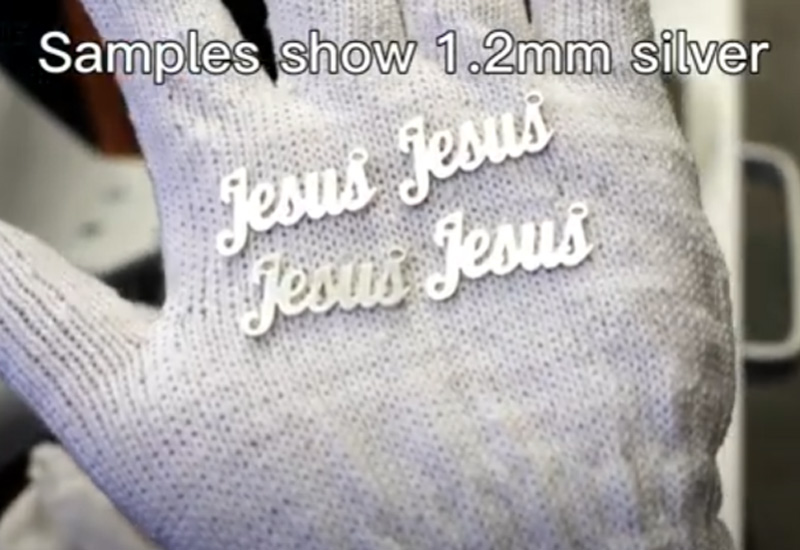

Vedetelo in azione su sottili fogli d'argento qui:

Libertà di progettazione nella segnaletica personalizzata

I tagli dritti fanno parte del passato. Oggi è possibile scolpire curve, creare strati interconnessi e persino aggiungere smussi 3D, il tutto in una sola passata. Per le microinsegne o le piccole targhe decorative, il modello La più piccola macchina per il taglio laser in fibra gestisce l'argento da 1,2 mm alla velocità della luce. È sufficiente inserire il DXF per vedere spuntare loghi intricati, pronti per l'anodizzazione o la verniciatura a polvere.

Le aziende produttrici di marchi sovrappongono lettere in alluminio da 2 mm a supporti acrilici colorati, senza lasciare spazi vuoti. Le teste BOGONG con capacità di smussatura tagliano smussi a 45° senza dover mai sostituire gli utensili. Ciò significa finiture dei bordi di livello professionale per le insegne dell'ospitalità, le esposizioni museali o le indicazioni stradali in ufficio, direttamente dalla macchina.

Con la gamma di macchine laser BOGONG, dalle agili 3020 e le più piccole macchine per il taglio laser in fibra alle pesanti serie 6000W-40KW e ai sistemi combinati tubo-piastra, avete uno strumento per ogni scenario. Meno scorie, HAZ più piccole, cicli più veloci e progetti che stupiscono. Se siete pronti ad aumentare il vostro livello di lavorazione del metallo, BOGONG Laser ha l'attrezzatura e l'esperienza per farlo.