-

Strada Shunhua, città di Jinan, Shandong

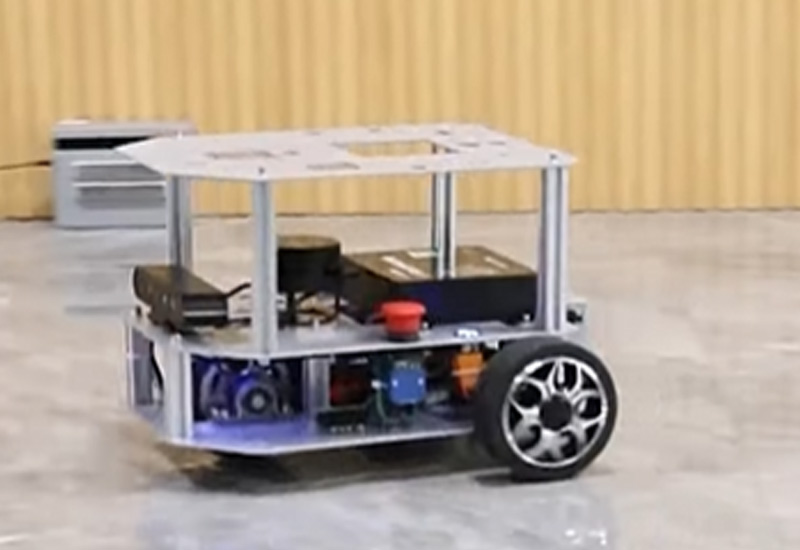

Factory-Direct Laser Cutting for Industrial Robot Chassis Components

Factory-direct laser for robot chassis: faster turnarounds, cleaner edges, lower waste. Work with a certified manufacturer to cut, bend, and weld smarter—globally.

Factory-direct laser reducing deals substantial benefits for making commercial robotic framework elements. This system delivers high preciseness, productivity, and also concept flexibility, enabling the production of complex, light in weight, and also heavy duty designs. Through dealing with the need for intermediators, producers can improve their supply establishment, minimize expenses, as well as speed up the development method.Let’s dive into why it makes sense and how BOGONG Laser’s lineup—direct from the factory—has got your back.

Why Factory‑Direct Matters

Shorter loops, fewer tickets. You talk to the Laser Cutting Machine Factory engineers, not a relay team. Faster DFM, real answers, fewer misreads.

Cleaner commercial path. One contract, one warranty path, less finger-pointing when something goes sideways.

Fewer translation losses. CAM tweaks, nesting rules, pierce strategy—change requests land straight in the team that touches the code.

OEM/ODM ready. When you need a jig, a tab-and-slot tweak, or special safety interlocks, you don’t wait on a reseller. It’s done by the people who build the machine.

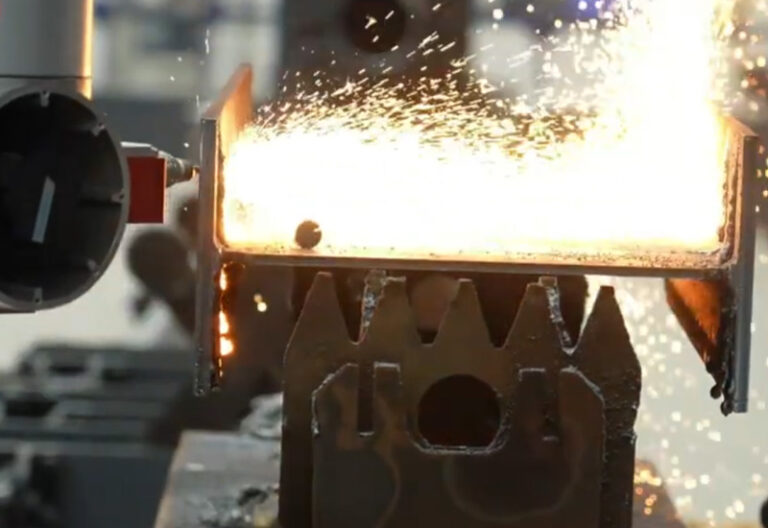

Why laser for robot chassis plate and frames

- Tight geometry without drama. Laser keeps the heat-affected zone small, so flatness stays sane after cutting. Holes, slots, datum features line up, and downstream bending hits spec more often.

- No hard tooling. Program, nest, run. That’s how you survive model churn and first-article builds.

- Mixed material, mixed thickness? Fiber laser eats thin-to-mid plate all day and toggles between carbon steel, stainless, and aluminum with minimal fuss.

Where laser fits vs. other processes (quick compare)

| Process | Edge / Precision | Thermal Impact | Throughput (thin–mid plate) | Typical Use in Chassis |

|---|---|---|---|---|

| Laser | Clean edge, fine detail | Basso | High, fast changeover | Base plates, brackets, gussets, rail panels |

| Plasma | Coarser edge | Alto | High on thick plate | Heavy frames where finish isn’t critical |

| Getto d'acqua | Very clean edge | Nessuno | Slower, higher run cost | Heat-sensitive parts, special laminates |

Tackling Pain Points

Customers often hit these snags on the shop floor:

Material Distortion: Thin sheets curl under heat.

Misaligned Cuts: Robot mounts mis‑register by a hair’s breadth.

Downtime for Tweaks: Every time you swap sheet types, someone has to re‑tune.

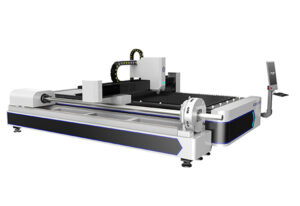

Selection guide

| Tipo di macchina | Best Scenario | Key Benefit |

|---|---|---|

Macchina per il taglio laser in fibra | Thin‑plate chassis skirts | Clean edges, low heat warp |

5050 Macchina per il taglio laser a fibra | Compact cell production | Space‑saving, easy integration |

Tagliatrice automatica del tubo del laser di caricamento | Round/rectangular frame tubes | Automated feed, hands‑free operation |

Macchina per il taglio laser della piastra e del tubo in fibra combinata | Mixed sheet + tube workflows | One‑stop cutting for parts + brackets |

How Industry‑Level Automation Boosts Throughput

Once you plug a robot into a factory‑direct Laser Cutting Machine Manufacturer’s control system, you unlock full‑line automation. Coil feeders, auto‑nesting software, and part‑stacking robots all talk to a single HMI. You’ll cut batch changeovers from hours down to minutes. That’s less babysitting and more running another job.

Case in Point: Chassis Bracket Batch Runs

If you’ve got 200 identical brackets to laser‑cut from stainless. Swapping plate thickness normally means re‑aligning focal height and edge purge pressure. With BOGONG Laser’s “smart head,” the machine auto‑senses material and locks in you’re golden. You drop a new bundle, hit “go,” and walk away.

Flexibility for Growth

Maybe today you cut simple flat plates; tomorrow you add bent tubes, or a thicker alloy. A Laser Cutting Machine Factory setup lets you scale: add a module, load a preset, or swap heads. You stay agile without ripping out hardware. And direct from BOGONG Laser, upgrades and spare parts are a phone call away—no “order back‑order” nightmares.

Nesting Optimization and Material Yield

Even the best laser won’t save you if your flats are wasted in the nest. That’s why top‑tier software comes standard—auto‑nesting that groups parts snug, minimizes kerf losses, and spits out real‑time scrap estimates. Less wasted steel means more chassis per coil, giving you a healthier margin every run.

Sealing the Deal with BOGONG Laser

BOGONG Laser isn’t just a Laser Cutting Machine Factory; we’re partners in your chassis‑making mission. From global B2B clients in automotive and electronics to bespoke OEM lines, we back every system with multilingual support, CE/ISO/SGS certifications, and 425+ proven project roll‑outs. When you buy direct, you get:

Full‑cycle support: commissioning, training, and remote tune‑ups.

Transparent R&D: input on the next‑gen auto‑focus heads and gas modulation algorithms.

Global parts reach: spares shipped to 160+ countries without extra markup.

Interested in upping your chassis game? Fill in the form to contact BOGONG Laser.