-

Strada Shunhua, città di Jinan, Shandong

Qual è la differenza tra le macchine di marcatura laser 2D, 3D e 2.5D?

In primo luogo, il mondo del laser è grande, in base alla diversa lunghezza d'onda del laser, il laser si divide in laser CO2, laser a fibra, laser UV, laser verde e così via. Diversi tipi di laser, diverse applicazioni. Oggi parliamo della macchina per l'incisione laser in fibra.

Dall'applicazione:

Il laser a fibra è utilizzato principalmente per materiali metallici e alcuni materiali plastici, come SS, CS, ottone, AL, similpelle, ardesia e plastica ABS, PU ecc.

Dalla potenza del laser:

Il laser a fibra si divide in macchina di marcatura laser a fibra (da 20w a 300w) e macchina di taglio laser a fibra (da 1,5kw a 40kw).

Dalla sorgente laser:

La sorgente laser si divide in sorgente laser di tipo pulsato e sorgente laser di tipo CW. La potenza laser da 20w a 300w appartiene alla sorgente laser pulsata e da 1,5kw a 40kw appartiene alla sorgente laser CW.

Dalla testa di Galvo:

Che si tratti di laser a CO2 o di laser a fibre o di altri tipi di laser, ci sono laser 2D e laser 3D.

Laser a fibra 2D:

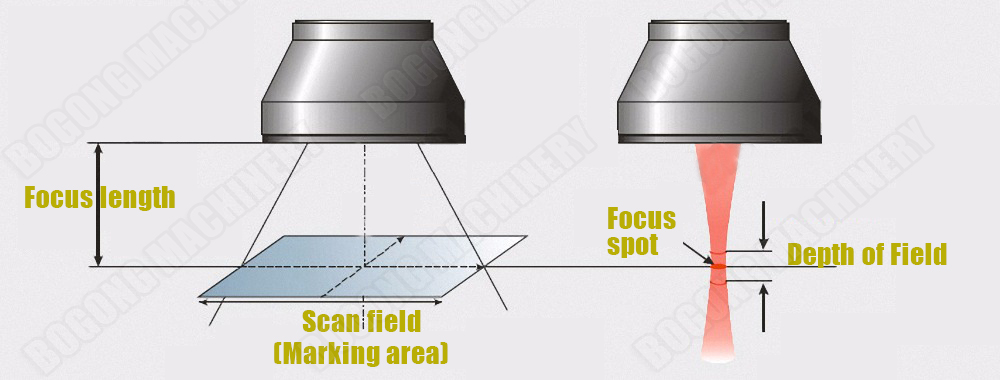

L'area di lavoro del laser a fibra 2D è opzionale, come: 100x100 mm, 150x150 mm, 175x175 mm, 200x200 mm, 300x300 mm. In generale, 300x300 mm è l'area di lavoro più grande. Perché l'area di lavoro è opzionale?

Come abbiamo detto, a parità di potenza, un'area di lavoro più grande comporta un raggio laser più debole. Questo è il motivo per cui è necessario scegliere un'area di lavoro di 100x100 mm se si ha bisogno di incisioni profonde o di tagliare materiali sottili. Tuttavia, se necessario, è possibile scegliere 2 lenti. Quando si ha bisogno di marcare solo la superficie, si scelgono 200x200 mm o 300x300 mm. Quando si necessita di un'incisione profonda, si sceglie un'area di lavoro di 100x100 mm. Cambiare l'obiettivo da soli non è difficile.

Applicazione del laser a fibra 2D:

Il laser 2D ha solo l'asse X Y, non c'è l'asse Z. Questo è il motivo per cui può tagliare o incidere al massimo 1,5-2 mm, perché la profondità di messa a fuoco del laser 2D è di circa 2 mm quando si utilizza un obiettivo di 100x100 mm. Durante la profondità di messa a fuoco, la potenza del raggio laser è quasi la stessa. Al di sopra o al di sotto del fuoco, la potenza del laser cambia. Quando si va più in profondità, il punto di messa a fuoco cambia, ed è per questo che non può andare più in profondità.

Così ha fatto un riassunto dell'applicazione del laser a fibra 2D

1. Marcatura su superficie, area di lavoro 300x300mm

2. Incisione profonda, non risultato in rilievo, solo incisione profonda. Area di lavoro migliore 100x100mm, max. 150x150 mm

3. Taglio di materiale metallico morbido e sottile, come argento, oro, ottone, AL. Area di lavoro max. 100x100 mm, principalmente taglio di 2 mm e inferiore.

Applicazione laser 3D:

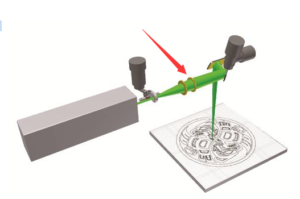

Il laser 3D ha 3 assi X Y Z e, all'interno della testa del laser, è presente uno specchio che può spostarsi in base alle variazioni del punto di messa a fuoco. In questo modo può mantenere la messa a fuoco sempre sulla superficie del materiale. Questo è il motivo per cui può incidere più in profondità rispetto al laser 2D.

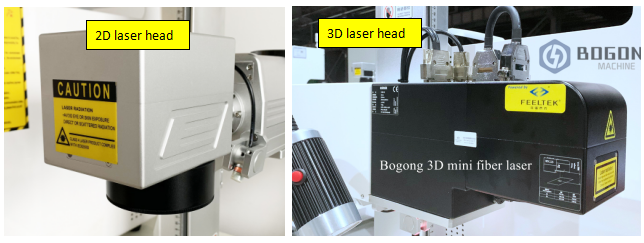

Anche dal punto di vista della testa Galvo si può notare la differenza. La testa del laser 2D è piccola e ha solo 2 specchi, uno per la direzione dell'asse X e l'altro per quella dell'asse Y.

La testa del laser 3D è più grande perché ha 3 specchi e lo specchio dell'asse Z può muoversi, quindi la testa 3D è più grande.

Fare una sintesi di Applicazione laser 3D

Il laser 3D è di 2 tipi: Incisione 3D a rilievo e area di lavoro 3D di grandi dimensioni

Abbiamo menzionato il laser 2d max. Area di lavoro è 300x300mm. Quindi la grande area di lavoro 3d può raggiungere 600x600mm o più grande.

E poiché una grande area di lavoro è sempre caratterizzata da una sorgente laser più debole. Quindi anche il laser 3d, se ha una grande area di lavoro, non può fare incisioni profonde, ma solo marcature superficiali.

1.Incisione a rilievo

2. Incisione

3. Grande area di lavoro per l'incisione

La testa del laser 2D e del laser 3D è diversa, quindi anche il software e il funzionamento sono diversi.

Applicazione del laser a fibra 2.5D:

Il laser 2.5D è in grado di completare tutti i lavori laser 2D e di eseguire incisioni laser 3D su lastre piane. Il 2.5D NON può eseguire incisioni 3D su parti curve.

Dal punto di vista tecnico, l'abbiamo chiamata 2.5D perché la testa laser è ancora una testa laser 2D, ma 2.5D con pilastro di sollevamento motorizzato. Il software può controllare il movimento della testa del laser durante il funzionamento della macchina, in modo da ottenere un'incisione 3D.

significa laser 3D, specchio dell'asse Z all'interno della testa del laser per muoversi avanti e indietro; 2,5D, asse Z sta per il terzo specchio per muoversi automaticamente

Laser 3D, il pilastro può essere di tipo manuale perché lo specchio dell'asse Z si trova all'interno della testa galvanica. (Ma può anche essere di tipo motorizzato, come nell'immagine precedente).

2.5D, montante deve essere tipo motorizzato. Poiché la testa del laser deve regolare nuovamente la messa a fuoco durante l'incisione, controllare l'immagine sopra.

Per ulteriori informazioni, potete consultare i nostri video su YouTube.

Spero che tutto sia chiaro per voi.

Grazie

Sherry from BOGONG team.