-

Strada Shunhua, città di Jinan, Shandong

Laser Cutting for Container Manufacturing Bulk Procurement and Customization

Discover how laser cutting boosts container manufacturing: cut lead times, ensure ISO-grade precision, and scale custom bulk runs with BOGONG Laser.

Laser cutting in container manufacturing supplies both bulk procurement advantages and personalization alternatives. It allows for precise and efficient cutting of materials, enabling the development of personalized styles, ventilation, gain access to factors, and other adjustments to common shipping containers, while keeping their structural integrity.

Why Laser Fits Bulk Container Work

Laser lines thrive on repeatability. Programs—not manual setups—drive the cut. Once your toolpaths, pierce strategy, and lead-ins/lead-outs are locked, you run part after part with the same edge quality and hole accuracy. Nesting squeezes more value from every sheet. Kerf compensation keeps final sizes honest, so tabs, slots, and hinge windows land where they should.

In practice:

Nesting: Packs parts tight by rotating and spacing intelligently; boosts yield and reduces scrap handling.

Kerf compensation: Offsets beam width so fit-ups stay consistent across lots.

Common-line cutting: Shares cut edges between parts to cut cycle time and heat input.

Micro-joints (tabbing): Stabilizes small features so nothing tips and mars the cut face.

Laser Cutting Machine Factory: Throughput with Control

A true laser cutting machine factory doesn’t just cut—it orchestrates. Nest-cut software and live sheet tracking load the queue, match materials, and slash idle time between batches. With high-power fiber systems, both plate and tube come off the table with tight, repeatable precision. Parts head straight to welding and assembly—no extra filing, hand-fit, or jig tweaking.

Shop-floor realities that help you hit dates:

Offline programming feeds the line while the current job runs.

Automated load/unload keeps the machine cutting, not waiting.

Remnant management tags leftover sheets for the next nest.

Barcode/lot tracking ties every part to heat numbers and revisions.

Bulk Doesn’t Mean “One Size Fits All”

Digital setups make revision control simple. You can tweak features per batch—extra drain holes, revised hinge slots, updated nameplates—without retooling.

Typical Container Mods Enabled by Laser Cutting

| Feature (Container Use) | What the Laser Delivers | Downstream Win |

|---|---|---|

Side-door and window cutouts  | Clean corners, tight radii, low dross | Fast fit-up, cleaner seals |

Ventilation slots/grilles | Repeatable patterns, burr-light edges | Better airflow, fewer re-punches |

Floor/drain holes | True-to-size, consistent locations | Quicker plumbing installs |

Hinge/lock keepers | Accurate slot-to-tab relationships | Doors align, no bind |

| Nameplates/labels | On-sheet engraving or cut text | Traceability that doesn’t peel |

| Cable/pipe penetrations | Notched profiles on tube/angle | Neater MEP routing |

Standards-Ready Container Parts

Container frames, panels, and corner posts need consistent fit. Laser-cut edges help frames bolt up square and door gaps seal cleanly. Keeping cuts aligned with relevant ISO flatness and dimensional rules reduces shimming and grind-backs. You spend time welding and assembling, not rescuing parts.

Quality gates that matter:

First Article Inspection (FAI) on new or revised parts.

SPC checks on critical holes/slots.

Fixture verification so sub-frames stay square through weld.

Material cert capture (MTRs) tied to lot IDs for traceability.

Control Heat, Beat Warpage

Thick profiles and long seams can stack heat fast. Smart path planning, pulse control, and bidirectional scanning shrink the heat-affected zone (HAZ). Sequencing spreads heat across the sheet to keep plates flatter and minimize camber.

Process levers your team can call out in the RFQ:

Limit pierce count where possible; prefer continuous paths.

Ask for heat-map sequencing on wide panels.

Specify an edge-quality class e weld-prep readiness (e.g., oxide removal, wipe).

Define slot-to-tab clearance classes by joint type instead of hard numbers when early.

Proof in Practice

| Batch Size | Lead Time Trend | Material Yield | Dimensional Stability | Downstream Impact |

|---|---|---|---|---|

| Prototype-to-Pilot | Shortens via digital setups | Improves with tight nesting | Consistent from first article | Faster feedback loops |

| Mid-Volume | Compresses with automated loading | Rises as remnants are reused | Holds steady across shifts | Smoother weld prep |

| Full-Scale | Levels out with continuous runs | Optimized via common-line cuts | Stays uniform across lots | Fewer fit-up fixes |

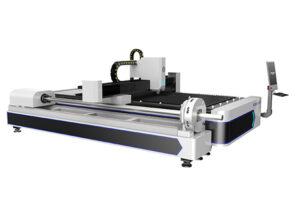

Suggested Machines from BOGONG Laser

Tagliatrice automatica del tubo del laser di caricamento — True plug-and-play automation for tube and profile, from kitting to full pallets.

5050 Macchina per il taglio laser a fibra — Compact footprint that scales from prototypes to steady production.

Macchina per il taglio laser a fibra conica — Handles complex bevels on corner posts and structural members in one pass.

Macchina per il taglio laser della piastra e del tubo in fibra combinata — Swap between plate and pipe without a line change.

Why BOGONG Laser for Bulk Container Work

A Laser BOGONG, we blend factory-scale capacity with the flexibility of a job shop. Our CE, ISO9001, SGS e FDA certifications back every run. You get one point of contact for fiber or CO₂ cutting, bulk order management, and global shipping to 160+ paesi. Over 9,000 clients trust our CNC systems for mission-critical containers.

What that means for you:

Throughput you can plan around: automated cells, live queueing, and remnant reuse.

Consistent parts: controlled kerf, stable edge quality, and documented checks.

Change-friendly: digital revisions flow straight to the cut list without retooling.

Logistics handled: consolidated kitting, clear labels, and export-ready packing.

Summarize

Laser cutting streamlines container builds at scale while enabling customization. Programmed toolpaths, nesting, kerf comp, common-line cuts, micro-joints boost yield and repeatability. Automated loading, tracking, QC cut lead time. Clean cutouts, vents, slots fit fast, with less heat and warp. Choosing the right cutting machine from BOGONG will help you get twice the result with half the effort.

Fill the form and feel free to talk with us!