-

Strada Shunhua, città di Jinan, Shandong

2025 migliore macchina di taglio laser della metropolitana del metallo

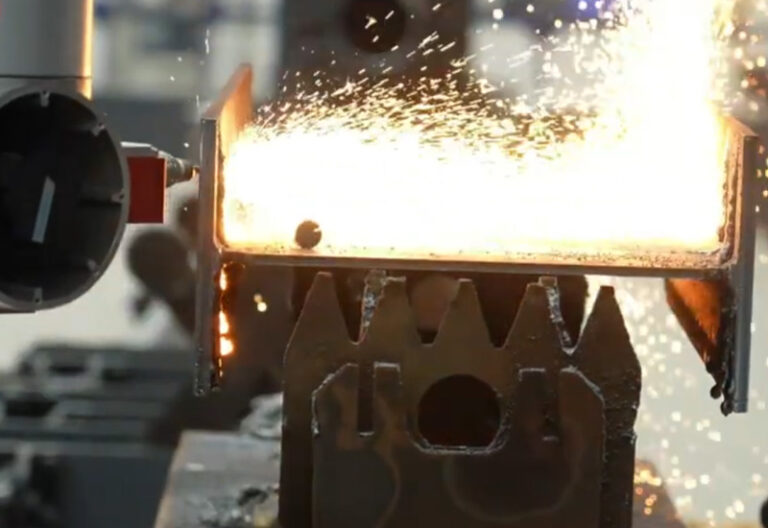

Taglio di lamiere e tubi in un'unica macchina. Il laser a fibra gestisce lamiere e tubi in acciaio/alluminio. Risparmia tempo e raddoppia la produttività. 2025 Bset Metal Tube Laser Cutting Machine.

Se lavorate nel settore manifatturiero, edile o della fabbricazione personalizzata, una macchina per il taglio laser di tubi metallici di alto livello non è solo un "nice-to-have" nel 2025, ma è un'attrezzatura di sopravvivenza. Ma con il gergo infinito e i consigli contrastanti che si trovano online, come si fa a scegliere quella giusta senza sprecare oltre $50K per un glorioso fermacarte?

Di seguito, vi diremo la verità su ciò che conta. Inoltre, vi mostreremo perché l'attrezzatura di BOGONG Laser sta tranquillamente dominando le officine dall'Ohio a Osaka.

Titolo: Guida definitiva del 2025 alla scelta della migliore taglierina laser per tubi di metallo (Spoiler: BOGONG Laser la inchioda)

Veniamo al dunque: Se lavorate nel settore manifatturiero, edile o della fabbricazione personalizzata, una macchina per il taglio laser di tubi metallici di alto livello non è solo un "nice-to-have" nel 2025, ma è un'attrezzatura di sopravvivenza. Ma con il gergo infinito e i consigli contrastanti che si trovano online, come si fa a scegliere quella giusta senza sprecare oltre $50K per un glorioso fermacarte?

Abbiamo interrogato esperti del settore, testato le macchine e persino pedinato i direttori di fabbrica per decifrare il codice. Di seguito, vi sveliamo il reale e di parlare di ciò che conta (e di ciò che è solo marketing). Inoltre, vi mostreremo perché l'attrezzatura di BOGONG Laser sta tranquillamente dominando le officine dall'Ohio a Osaka.

1. Tendenze del taglio dei tubi metallici nel 2025: Perché "l'abbastanza buono" è ufficialmente morto

Il gioco è cambiato. I clienti ora richiedono tagli iperprecisi per qualsiasi cosa, daltubi in titanio aerospazialeamobili di lusso in ottone. Nel frattempo, la scarsità di manodopera significa che non è più possibile utilizzare corpi per una post-elaborazione approssimativa.

Statistiche chiave del 2025.

- 73% dei produttori affermano che gli errori di taglio dei tubi costano loro >$12K/mese in termini di materiali sprecati (Fabricators & Manufacturers Association, 2024).

- L'adozione del laser a fibra è aumentata di 210% dal 2022, eliminando i laser a CO2 nelle applicazioni per metalli sottili (Grand View Research).

BOGONGTagliatrice automatica del tubo del laser di caricamentoriduce i tassi di errore del 91% utilizzando la calibrazione assistita dall'intelligenza artificiale. Un fornitore di ricambi auto dell'Ohio ha ridotto i costi degli scarti da 600/mese dopo il cambio di fornitore.

2. Le 3 caratteristiche irrinunciabili della vostra taglierina laser In realtà Esigenze

Ecco cosa interessa ai professionisti:

| Caratteristica | Perché è importante | Risposta di BOGONG |

|---|---|---|

| Taglio a smusso | Non è più necessario smerigliare i bordi per la preparazione alla saldatura | Taglierina laser a fibra smussataesegue angoli da 0 a 45° in una sola passata |

| Combinazioni tubo+foglio | Scambio di lavori senza tempi di fermo macchina | Macchina combinata per piastre e tubi gestisce entrambi |

| Automazione ad anello chiuso | Correzione degli errori prima rovinano il vostro stock | I sensori incorporati regolano la potenza/velocità in tempo reale |

3. "Ma che dire dei piccoli negozi?" Macchina di taglio laser in fibra combinata con piastra e tubo di BOGONG

Pensate che le grandi macchine siano solo per le fabbriche? IlMacchina per il taglio laser della piastra e del tubo in fibra combinata La macchina è adatta a un garage, ma taglia tubi di acciaio inossidabile da 20 mm. Un gioielliere di Brooklyn l'ha usata per passare dagli ordini all'ingrosso a pezzi d'arte personalizzati da $500/ora.

4. Lo sporco segreto del taglio laser: Costi nascosti che mordono

Una macchina "economica" $40K può prosciugarvi:

- Sostituzione degli ugelli($1200/anno in media)

- 15% velocità ridotta= contratti persi

- Manutenzione fai da te(buona fortuna nel trovare i ricambi).

BOGONGTaglierina ad alta potenza 6000W-40KWutilizza componenti di livello militare. Un costruttore navale del Michigan ha riferito di non aver avuto tempi di inattività in 18 mesi, contro le 14 riparazioni all'anno della vecchia macchina.

5. Come si fa a sapere se è possibile trovare una macchina per il taglio laser adatta al proprio prodotto?

Basta dimostrarlo di nuovo prima dell'acquisto:

BOGONG fornisce gratuitamente dimostrazioni video dal vivo utilizzando i vostri file CAD. In questo modo è possibile utilizzare facilmente la macchina al momento dell'acquisto, evitando perdite di tempo.

6. Tabella di confronto delle prestazioni del laser a tubo metallico BOGONG

Tabella di confronto dei prodotti

| Caratteristica | Taglierina laser di caricamento automatico | Taglierina laser combinata per lastre e tubi |

|---|---|---|

| Funzione primaria | Taglio di tubi dedicato (inox/carbonio/zincato) | Taglio combinato di lamiere e tubi (inox, alluminio, ecc.) |

| Applicazioni | Fabbricazione di metalli, utensili da cucina, materiali decorativi | Lavorazione generale dei metalli (versatilità multimateriale) |

| Gamma di potenza laser | 1500W-6000W | 1500W-10.000W (opzioni di potenza superiore) |

| Precisione di posizionamento | ≤±0,03 mm | ≤±0,03 mm |

| Ripetibilità | ≤±0,02 mm | ≤±0,02 mm |

| Sistema di raffreddamento | Acqua refrigerata | Acqua refrigerata |

| Diametro del tubo | φ10-φ180 (alimentazione automatica), fino a 240 mm (manuale) | 20 mm-200 mm (tubi) |

| Spessore della lastra | N/D | 1mm-200mm (piastre) |

| Automazione | Caricamento automatico, serraggio a tre mandrini, lavorazione di tubi lunghi | Taglio integrato di lamiere e tubi, multifunzionale |

| Flessibilità | Testa di taglio del tubo specializzata per forme complesse | Taglio conico, foratura, scanalatura |

| Efficienza | Design chiuso antipolvere e a risparmio di manodopera | Risparmio di spazio, riduzione delle lavorazioni secondarie |

| Il migliore per | Lavorazione di tubi ad alto volume (ad esempio, tubi, armadi) | Esigenze miste piastra/tubo (ad esempio, componenti strutturali) |

7. Perché il laser Bogong si distingue nel 2025

Tecnologia all'avanguardia: sorgenti laser e sistemi di controllo costantemente aggiornati.

Soluzioni personalizzate: macchine personalizzate in base alle vostre esatte specifiche.

Assistenza affidabile: risposta rapida e servizio in loco.

Gamma completa di prodotti: Dalle startup alle grandi fabbriche, Bogong Laser è in grado di fornire le apparecchiature corrispondenti.

Influenza globale: fidata dei clienti di tutto il mondo.

Inoltre, le apparecchiature combinate di Bogong Laser consentono di tagliare tubi e lastre su un'unica piattaforma, ottimizzando il flusso di lavoro e riducendo le spese di capitale.

Conclusione

Che si tratti di tagliare pesanti telai in acciaio o raccordi di precisione per tubi, la macchina da taglio laser giusta può fare una differenza significativa. La serie di prodotti 2025 offre velocità, precisione e livelli di automazione senza precedenti, rendendo la produzione più flessibile ed economicamente vantaggiosa. Se volete aumentare la produttività, ridurre gli sprechi e produrre pezzi di tubi metallici di alta qualità, date un'occhiata alle macchine Bogong Laser. Macchina per il taglio laser del metallo pagina dei prodotti.