-

Calle Shunhua, ciudad de Jinan, Shandong

Máquina de corte láser de fibra más pequeña para latón, oro, plata

Máquina de corte por láser de fibra más pequeña

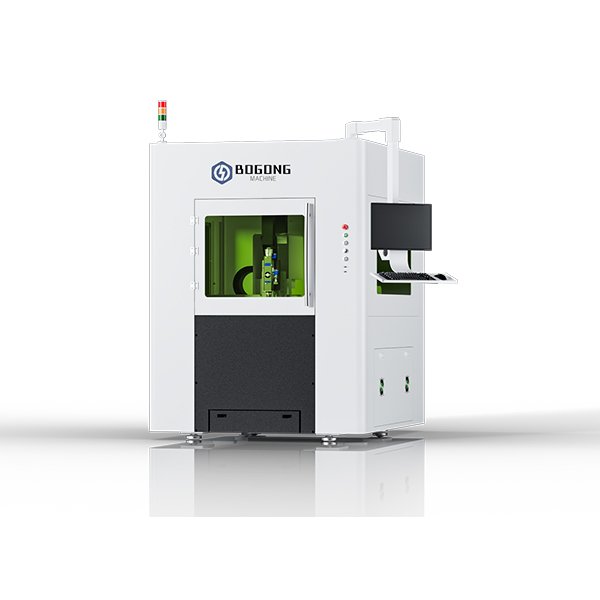

BOGONG 3030 máquina de corte por láser de fibra es el más pequeño de corte por láser para el metal, es fantástica manera de crear piezas únicas y personalizadas de forma rápida y sencilla. el tamaño de corte es de 300 * 300 mm, gabinete completo con diseño de seguridad, produce cortes limpios y suaves, por lo que es una opción eficaz para la artesanía. Sin embargo, hacer hermosas joyas de metal también requiere precisión y un toque de arte. Ahí es donde la pequeña cortadora láser de joyas BOGONG entra en juego. Esta máquina produce detalles excepcionales y resultados que a menudo superan las expectativas. También es versátil, capaz de cortar no sólo oro y plata, sino también materiales como cobre y acero inoxidable.

Si está interesado en crear joyas de metal únicas, la BOGONG 3030 de BOGONG LASER es todo lo que necesita. Su diseño compacto ahorra espacio, y viene con un controlador CNC automático y un software fácil de usar que lo hace accesible para todos, tanto si está empezando como si tiene años de experiencia. Es perfecta tanto para aficionados como para propietarios de pequeñas empresas.

- 200 Sets / Month Waiting for Sale En stock

- 2 años de garantía limitada para toda la máquina

- En línea (PayPal) y fuera de línea (T/T, tarjetas de débito y crédito)

- Asistencia técnica gratuita de por vida para usuarios finales y distribuidores

¿Está buscando la mejor máquina de corte por láser de precisión (1500W , 2000W o 3000W) para crear joyas de metal personalizadas como anillos, pendientes, colgantes, pulseras, gemelos, collares, broches y otros adornos personalizados de plata, oro, cobre o acero inoxidable? Eche un vistazo a las mini cortadoras de joyas por láser de fibra compactas más vendidas a precio de coste.

Rendimiento

- Medio láser - Láser de fibra óptica de estado sólido CW 1070 nm

- Potencia láser - Opciones de fuente de fibra de 1000 W a 3000 W

- Alimentación - 220v monofásico/ 380 V trifásico

- Precisión de posicionamiento - ≤±0,03 mm

- Precisión de repetibilidad - ≤±0,02mm

Sistema

- Sistema de accionamiento - Servo de bucle cerrado

- Modo de refrigeración - Agua refrigerada

El corte por láser de joyería metálica de diversas formas es una forma sencilla y eficaz de crear piezas personalizadas. Ofrece cortes rápidos, limpios y suaves. Sin embargo, la elaboración de hermosas joyas de metal requiere precisión y un toque delicado. Ahí es donde la cortadora láser pequeña BOGONG 3030. Ofrece detalles increíbles y resultados que superan las expectativas. Además, no sólo puede cortar oro y plata, sino también materiales como cobre y acero inoxidable.

Si está buscando hacer joyas de metal únicas, todo lo que necesita es la cortadora láser de fibra 3030 de BOGONG LASER. Es compacta, ahorrando espacio de trabajo precioso, y viene equipada con un controlador CNC automático junto con un software intuitivo que es fácil de usar, tanto si eres un principiante o un profesional experimentado. Es perfecta tanto para artesanos como para pequeños empresarios.

¿Qué es la joyería de metal?

La joyería metálica incluye una amplia gama de artículos como anillos, pendientes, collares, pulseras, broches, colgantes y gemelos, fabricados normalmente con materiales como oro, plata, cobre y acero inoxidable de color, entre otros metales preciosos.

La mayor parte de esta joyería se compone de piezas pequeñas, lo que exige un alto nivel de precisión de corte y un desperdicio mínimo. Los métodos de corte mecánicos tradicionales sencillamente no satisfacen las exigencias modernas de la fabricación de joyas. El corte por láser es la mejor solución, ya que ofrece velocidad, precisión, alta calidad y procesos no destructivos y respetuosos con el medio ambiente. Dado que los distintos metales tienen diferentes grados de blandura, dureza y reflectividad, los láseres de fibra son especialmente adecuados para conseguir cortes precisos en joyería metálica.

Máquina de corte por láser de fibra Industrias aplicables

Equipos mecánicos y eléctricos, fabricación de chapas metálicas, armarios, productos de acero inoxidable, accesorios de iluminación, piezas de automóvil, herramientas de ferretería, carteles publicitarios, artículos de decoración y otras industrias.

¿Cómo funciona?

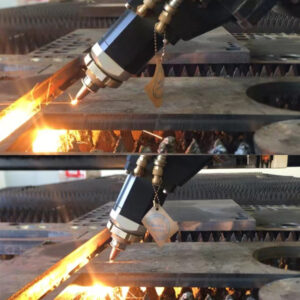

Las cortadoras láser de joyas de metal utilizan tecnología láser avanzada, y la forma en que los materiales interactúan con el láser es clave para el proceso. Aquí tienes un sencillo desglose paso a paso de cómo funciona:

1. Introducción del diseño: En primer lugar, se crea el diseño mediante software CAD. A continuación, este diseño se transforma en un formato legible por máquina mediante software CAM.

2. Generación láser: La cortadora utiliza un láser de CO2 o de fibra para producir un haz concentrado de luz de alta temperatura.

3. Enfoque del haz: El sistema óptico dirige este potente rayo láser a un punto específico de la superficie metálica para cortarla o grabarla.

4. Interacción con el material: El calor del láser afecta a diferentes metales de diversas maneras, por lo que los ajustes pueden cambiar dependiendo del material.

5. Movimiento controlado: El láser sigue el patrón de diseño que usted ha creado, moviéndose con precisión según las instrucciones del software.

6. Refrigeración: Un sistema de refrigeración eficaz es crucial para garantizar que el producto acabado conserve su forma y calidad originales.

7. Eliminación de residuos: Tras el proceso de corte, se limpian los restos de material para dar a la pieza un acabado pulido.

¿Por qué elegir una cortadora láser de precisión para cortar joyas de plata, oro y cobre? - Pros y Ventajas

✔ Diseño compacto y seguro: El cortador cuenta con vidrio anti-radiación estándar CE, por lo que es más seguro de operar.

✔ Corte de alta precisión: Utiliza un sistema de servoaccionamiento AC japonés importado para cortes rápidos y precisos.

✔ Movimiento preciso: El eje Y está diseñado con una transmisión de husillo de bolas de alta precisión, lo que garantiza cortes rectos incluso a altas velocidades.

✔ Construcción duradera: La máquina está construida para durar y es resistente a la deformación.

✔ Posicionamiento eficaz: Las pinzas neumáticas sujetan firmemente los materiales más finos, mientras que una mesa de cuchillas móvil acomoda las piezas más gruesas, garantizando la precisión.

✔ Blindaje protector: El diseño totalmente cerrado evita que se escape cualquier resto metálico durante el corte.

✔ Fácil recogida de residuos: Una bandeja de recogida debajo de la mesa de corte facilita la recogida y eliminación rápida del material sobrante.

**¿Por qué elegir el láser BOGONG?

BOGONG famoso por su calidad de los equipos láser y el servicio de servicio post-venta, Nuestras máquinas son versátiles y fáciles de usar, diseñado con todos los niveles de habilidad en mente. Por encima de todo, damos prioridad a la satisfacción del cliente. Ya sea un experto o un principiante, LÁSER BOGONG está aquí para apoyarle en cada paso del camino. Confíe en nosotros y en nuestro servicio, donde la excelencia y la innovación se unen para su éxito.

|