-

Calle Shunhua, ciudad de Jinan, Shandong

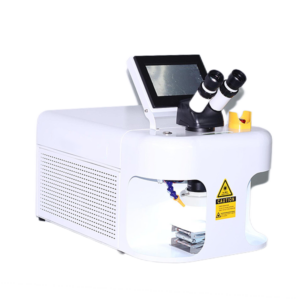

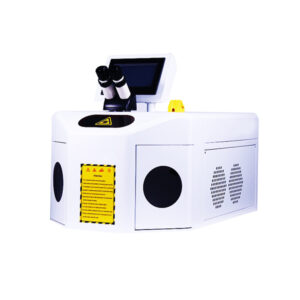

Soldador láser para joyería

venta de soldadora láser para joyería

For welding metals like aluminum, steel, copper, and various alloys, laser welding machines are the perfect choice with high speed and precision. Whether you’re looking for a manual or automated solution, our team of laser experts is ready to assist you in seamlessly integrating it into your production line.

Además, nuestras soluciones son valiosas para la investigación y el desarrollo, ya que contribuyen tanto a la mejora de procesos como al desarrollo de productos.

For welding metals like aluminum, steel, copper, and various alloys, laser welding machines are the perfect choice with high speed and precision. Whether you’re looking for a manual or automated solution, our team of laser experts is ready to assist you in seamlessly integrating it into your production line.

Además, nuestras soluciones son valiosas para la investigación y el desarrollo, ya que contribuyen tanto a la mejora de procesos como al desarrollo de productos.

Jewelry Laser Welding Machine jewelry laser welder for sale

YAG de sobremesa Máquina de soldadura láser para Joyería: Anillos y collares de oro, plata, titanio y metal

Las máquinas de soldadura láser YAG para joyería son populares en varias industrias, especialmente en la fabricación y reparación de joyas. Estas máquinas ofrecen varios beneficios, haciéndolas ideales para tareas como soldadura de reparación, soldadura por puntos, empalme e inserción en diferentes metales y aleaciones. Invertir en una soldadora láser para joyería puede mejorar significativamente la precisión, productividad y rentabilidad de su joyería.

Diseño compacto: Estas máquinas son pequeñas y portátiles, lo que facilita a los joyeros colocarlas en un banco de trabajo o escritorio sin ocupar demasiado espacio.

Micro Welding: YAG laser welders excel at “micro welding,” which allows for extremely precise welding on small components such as prongs, settings, and delicate chains without harming adjacent areas.

Mínima zona afectada por el calor: La soldadura láser produce un calor mínimo, lo que reduce el riesgo de distorsión, decoloración o daños en los materiales circundantes. Esto es especialmente importante cuando se trabaja con metales preciosos y piedras preciosas sensibles al calor.

Ajustes regulables: La máquina suele disponer de ajustes de potencia y tamaños de haz regulables, lo que permite a los operarios personalizar los parámetros de soldadura para cada tarea específica.

Facilidad de uso: A pesar de su avanzada tecnología, estas máquinas están diseñadas para ser fáciles de usar, haciéndolas accesibles a joyeros de todos los niveles de habilidad.

Rentables: Estas máquinas son adecuadas para joyerías más pequeñas, ya que ofrecen una solución de bajo coste para una soldadura de alta calidad.

Aplicaciones: Máquinas de soldadura láser para joyería puede utilizarse para diversas tareas, como reparar piezas rotas, cambiar el tamaño de los anillos, colocar cierres o fornituras, fijar garras y mucho más.

Venta caliente: Soldador láser de joyería 200W Máquina de soldadura láser para joyería con CCD para reparaciones de joyería Oro Plata Platino

Las máquinas de soldadura láser YAG para joyería son populares en varias industrias, especialmente en la fabricación y reparación de joyas. Estas máquinas ofrecen varios beneficios, haciéndolas ideales para tareas como soldadura de reparación, soldadura por puntos, empalme e inserción en diferentes metales y aleaciones. Invertir en una soldadora láser para joyería puede mejorar significativamente la precisión, productividad y rentabilidad de su joyería.

Diseño compacto: Estas máquinas son pequeñas y portátiles, lo que facilita a los joyeros colocarlas en un banco de trabajo o escritorio sin ocupar demasiado espacio.

Micro Welding: YAG laser welders excel at “micro welding,” which allows for extremely precise welding on small components such as prongs, settings, and delicate chains without harming adjacent areas.

Mínima zona afectada por el calor: La soldadura láser produce un calor mínimo, lo que reduce el riesgo de distorsión, decoloración o daños en los materiales circundantes. Esto es especialmente importante cuando se trabaja con metales preciosos y piedras preciosas sensibles al calor.

Ajustes regulables: La máquina suele disponer de ajustes de potencia y tamaños de haz regulables, lo que permite a los operarios personalizar los parámetros de soldadura para cada tarea específica.

Facilidad de uso: A pesar de su avanzada tecnología, estas máquinas están diseñadas para ser fáciles de usar, haciéndolas accesibles a joyeros de todos los niveles de habilidad.

Rentables: Estas máquinas son adecuadas para joyerías más pequeñas, ya que ofrecen una solución de bajo coste para una soldadura de alta calidad.

Aplicaciones: Máquinas de soldadura láser para joyería puede utilizarse para diversas tareas, como reparar piezas rotas, cambiar el tamaño de los anillos, colocar cierres o fornituras, fijar garras y mucho más.

Venta caliente: Soldador láser de joyería 200W Máquina de soldadura láser para joyería con CCD para reparaciones de joyería Oro Plata Platino

Máquina de soldadura láser para joyería BOGONG

ALTO RENDIMIENTO

La soldadora de joyas funciona con una fuente láser YAG de alta calidad, lo que permite realizar soldaduras rápidas con una deformación mínima, juntas de soldadura pequeñas y una zona afectada por el calor reducida. Cuenta con un sistema de observación CCD que proporciona una visión clara de la pieza de trabajo de soldadura y las juntas, mejorando su capacidad para realizar un procesamiento preciso de micro-tamaño y mejorar tanto la precisión como la eficiencia.

FÁCIL DE USAR

Este soldador láser para joyería viene con una pantalla táctil en color que simplifica el manejo, y está equipado con ruedas universales para facilitar su movilidad. Con múltiples modos de soldadura para elegir, puede ajustar fácilmente varios parámetros para satisfacer sus necesidades específicas. Además, esta soldadora láser es una opción rentable, ya que requiere menos consumibles. Su diseño ergonómico también ayuda a reducir la fatiga durante las largas horas de trabajo.

AMPLIAS APLICACIONES

Esta máquina de soldadura láser es versátil y muy utilizada en muchos campos, como piezas pequeñas, anillos, colgantes, pulseras, dentaduras postizas, interfaces de cargadores de teléfonos móviles, hardware, relojes, artículos deportivos, palos de golf y equipos médicos. Es especialmente eficaz para tareas como parchear agujeros, soldar agujeros de grano por puntos, reparar costuras y unir piezas incrustadas en joyería de oro y plata.

La soldadora de joyas funciona con una fuente láser YAG de alta calidad, lo que permite realizar soldaduras rápidas con una deformación mínima, juntas de soldadura pequeñas y una zona afectada por el calor reducida. Cuenta con un sistema de observación CCD que proporciona una visión clara de la pieza de trabajo de soldadura y las juntas, mejorando su capacidad para realizar un procesamiento preciso de micro-tamaño y mejorar tanto la precisión como la eficiencia.

FÁCIL DE USAR

Este soldador láser para joyería viene con una pantalla táctil en color que simplifica el manejo, y está equipado con ruedas universales para facilitar su movilidad. Con múltiples modos de soldadura para elegir, puede ajustar fácilmente varios parámetros para satisfacer sus necesidades específicas. Además, esta soldadora láser es una opción rentable, ya que requiere menos consumibles. Su diseño ergonómico también ayuda a reducir la fatiga durante las largas horas de trabajo.

AMPLIAS APLICACIONES

Esta máquina de soldadura láser es versátil y muy utilizada en muchos campos, como piezas pequeñas, anillos, colgantes, pulseras, dentaduras postizas, interfaces de cargadores de teléfonos móviles, hardware, relojes, artículos deportivos, palos de golf y equipos médicos. Es especialmente eficaz para tareas como parchear agujeros, soldar agujeros de grano por puntos, reparar costuras y unir piezas incrustadas en joyería de oro y plata.

Application of Jewelry Laser Welder

• Join small seams on gold, silver, platinum, and palladium

• Repair porosity and pinholes

• Re-tip and rebuild prongs

• Attach jump rings and bails

• Solder chains without removing stones

• Fix cracks on shanks and bands

• Add metal for resizing

• Tack components before full assembly

• Solder near heat sensitive stones

• Rebuild gallery sections

• Reattach settings and heads

• Fill gaps and pits on cast pieces

• Attach findings on earrings and pendants

• Repair bracelets without weakening nearby links

• Work on thin metal without overheating it

• Add decorative elements or small components

• Clean up and reshape small details with precision

• Repair porosity and pinholes

• Re-tip and rebuild prongs

• Attach jump rings and bails

• Solder chains without removing stones

• Fix cracks on shanks and bands

• Add metal for resizing

• Tack components before full assembly

• Solder near heat sensitive stones

• Rebuild gallery sections

• Reattach settings and heads

• Fill gaps and pits on cast pieces

• Attach findings on earrings and pendants

• Repair bracelets without weakening nearby links

• Work on thin metal without overheating it

• Add decorative elements or small components

• Clean up and reshape small details with precision

¿Partes principales de la máquina de soldadura láser para joyería?

Microscopio y sistema de cámara

El microscopio binocular cuenta con una pantalla síncrona CCD, que proporciona una forma cómoda de observar el efecto de soldadura de su muestra en tiempo real.

Interfaz

La pantalla táctil en color ofrece una interfaz fácil de usar que permite ajustar los parámetros de forma sencilla y manejarla con facilidad.

Tubo de soplado de aire

El ángulo del tubo de soplado es ajustable y su diseño compacto ahorra un valioso espacio en el estudio. Al soplar gas nitrógeno o argón, ayuda a evitar la oxidación y el ennegrecimiento de la pieza de trabajo.

Interruptor de pedal

Un pedal externo controla la emisión láser: basta con pulsarlo una vez para activar la luz, lo que facilita el uso y el cambio entre controles.

El microscopio binocular cuenta con una pantalla síncrona CCD, que proporciona una forma cómoda de observar el efecto de soldadura de su muestra en tiempo real.

Interfaz

La pantalla táctil en color ofrece una interfaz fácil de usar que permite ajustar los parámetros de forma sencilla y manejarla con facilidad.

Tubo de soplado de aire

El ángulo del tubo de soplado es ajustable y su diseño compacto ahorra un valioso espacio en el estudio. Al soplar gas nitrógeno o argón, ayuda a evitar la oxidación y el ennegrecimiento de la pieza de trabajo.

Interruptor de pedal

Un pedal externo controla la emisión láser: basta con pulsarlo una vez para activar la luz, lo que facilita el uso y el cambio entre controles.

BOGONG tipo Mini Joyería Soldador Láser Mostrar

Hay varios tipos de Mini Soldador Láser para su elección, se puede ver en el video de la izquierda. elegir el adecuado para su uso.

Minisoldadora láser más popular

El coste de BOGONG‘s jewelry laser welder is competitively priced, offering exceptional value for its advanced features and high-quality performance, making it an ideal investment for jewelers looking to enhance precision and efficiency in their work, ensuring quick returns while maintaining affordability for both small and large jewelry businesses.

Soldador Láser para Joyería Pro de 200W con CCD en su interior.

Soldador láser para joyería 200 pro con piezas láser especiales en su interior, soldador láser de alto rendimiento.

Soldadora láser portátil refrigerada por aire

Soldador láser para joyería Bogong 150W

PONERSE EN CONTACTO

CONTACTO BOGONG

Whether you are interested in our Fiber Laser Cutting Machine our team at Bogong Laser is here to provide professional consultation and tailored solutions. Get in touch today to discuss your specific laser machine requirements and receive expert support from Bogong Laser.