-

Shunhua Road, Jinan City, Shandong

Faserlaser-Metallschneidemaschine Hersteller

Worauf sollten Sie wirklich achten, wenn Sie sich einen Hersteller von Faserlaser-Metallschneidemaschinen ansehen? Es kommt auf die Eigenschaften an, die sich direkt darauf auswirken, wie viel Arbeit Sie erledigen können, wie hervorragend diese Arbeit ist und wie viel sie Sie kostet.

Die Metallverarbeitung hat ihre schwierigen Seiten. Der Umgang mit einer langsamen Produktion, die zu Engpässen führt, das Wegwerfen teurer Produkte aufgrund ungenauer Schnitte oder das häufige Ausbessern von Bauteilen, weil sie nicht ganz passend sind - diese Punkte kosten Zeit und Geld. Eine gute Faserlaserschneidmaschine? Sie ist darauf ausgelegt, genau diese Art von Frustrationen zu bewältigen.

Worauf sollten Sie also wirklich achten, wenn Sie sich einen Hersteller von Faserlaser-Metallschneidemaschinen ansehen? Es kommt auf die Eigenschaften an, die sich direkt darauf auswirken, wie viel Arbeit Sie erledigen können, wie hervorragend diese Arbeit ist und wie viel sie Sie kostet. Lassen Sie uns die entscheidenden Dinge aufschlüsseln.

Tempo: Kurbel die Produktion hoch!

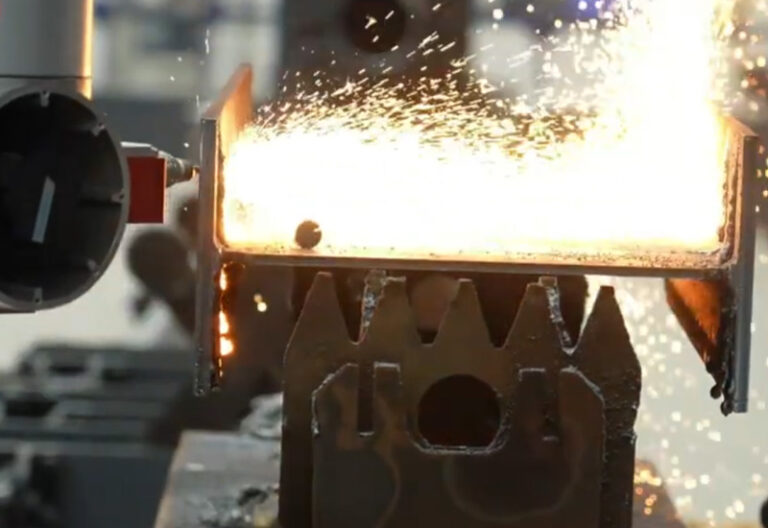

Zunächst einmal die Geschwindigkeit. Faserlaser sind sehr schnell, wenn es um die Reduzierung von Stahl geht.

Warum so viel Wert auf die Geschwindigkeit legen? Ganz einfach: Geschwindigkeit bedeutet mehr Komponenten, viel schneller. Mehr Bauteile bedeuten, dass Sie größere Aufträge annehmen, die knappen Fristen Ihrer Kunden einhalten und generell mehr Geld verdienen können. Wenn Ihre Ausrüstung schneller schneidet, läuft Ihr gesamter Betrieb schneller. Das hilft Ihnen, Produktionsengpässe zu beseitigen und Ihr Geschäft in Schwung zu bringen. Denken Sie daran, die Arbeit schneller umzukehren - das freut die Kunden und hält Ihre Geräte in Schwung.

Präzision: Kosten senken, nicht Ecken

Niemand hat die Absicht, ein nützliches Produkt zu zerstören. Präzision beim Schneiden von Stahl ist eine große Sache. Faserlaser-Maschinen sind für ihre unglaubliche Präzision bekannt. Wir sprechen hier von engen Widerständen, manchmal mit einer Positionierungsgenauigkeit von kleinen Millimeterteilen, wie pm0,03 mm.

Warum ist diese Genauigkeit so wichtig? Zunächst einmal, weil weniger Abfall anfällt. Wenn Ihre Schnitte exakt sind, müssen Sie keine teuren Metallrohlinge wegwerfen. Das spart schon mal Geld. Außerdem passen exakte Teile perfekt zusammen, was die Montage reibungsloser und viel schneller macht. Sie müssen sich nicht mehr mit Teilen herumschlagen, die nicht ganz zueinander passen! Hohe Genauigkeit bedeutet viel weniger Nacharbeit und ein saubereres Endprodukt, was Ihre Kunden sicher zu schätzen wissen werden.

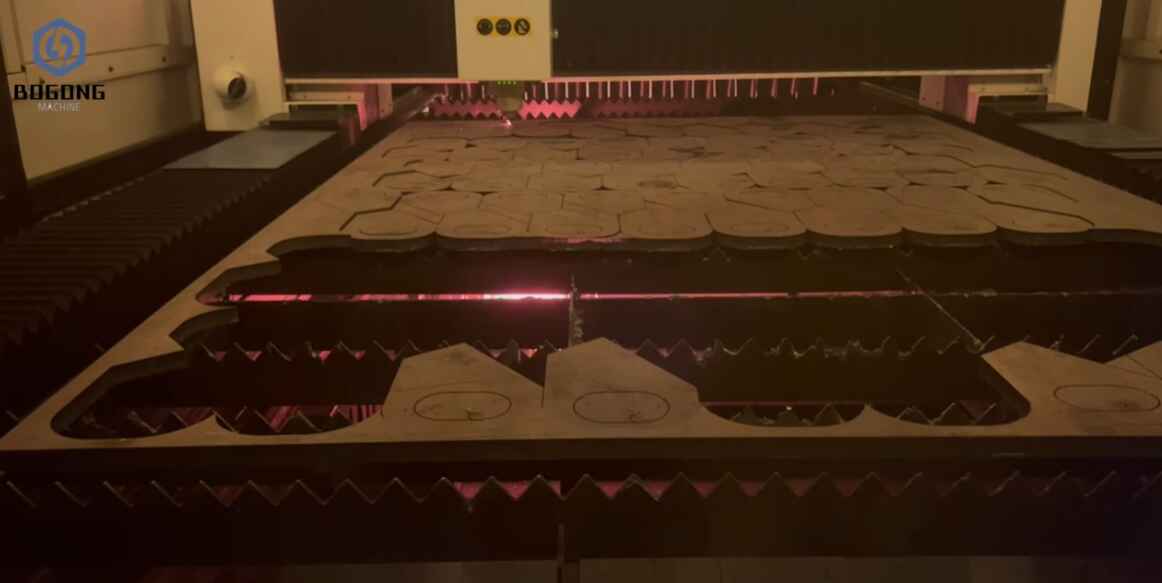

Vielseitigkeit: Schneidet fast alles

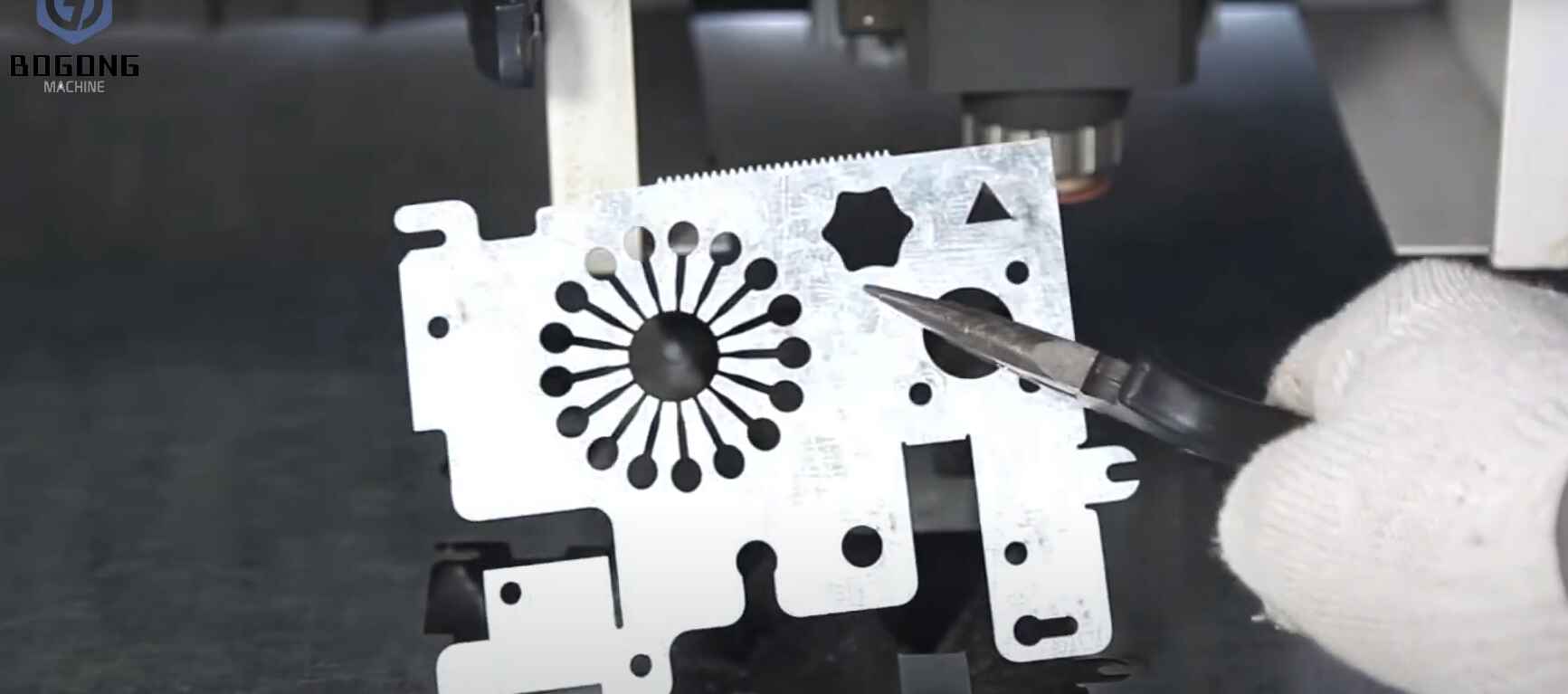

Einer der coolsten Aspekte des Faserlaserschneidens ist seine Fähigkeit, viele verschiedene Metalle zu schneiden - Kohlenstoffstahl, Edelstahl, leichtes Aluminium, Kupfer, Messing, was immer Sie wollen. Wenn Ihr Unternehmen mit zahlreichen Metallen zu tun hat, ist diese Flexibilität ein entscheidender Vorteil.

Mit einem einzigen Gerät, das verschiedene Stähle bearbeiten kann, brauchen Sie nicht eine ganze Armee verschiedener Schneidwerkzeuge. Es vereinfacht Ihre Konfiguration und ermöglicht Ihnen einen einfachen Wechsel zwischen den Aufgaben. Diese Flexibilität bedeutet, dass Sie ein breiteres Spektrum an Aufgaben bewältigen können, wodurch sich Ihre Möglichkeiten erweitern und möglicherweise neue Arten von Aufgaben hinzukommen, die Sie vorher nicht erledigen konnten. Zum Beispiel diese Beliebteste Faserlaser-Metallschneider können die Schneidanforderungen für fast alle Materialien erfüllen.

Dickenmanagement: Von papierdünn bis plattendick

Stahl gibt es in allen Dichten, richtig? Von superdünnem Material bis hin zu stabilen Platten. Ein großer Faserlaserhersteller verwendet Geräte mit verschiedenen Leistungsstufen (von einigen Kilowatt bis zu 40 kW oder sogar mehr), um diese Anordnung zu verwalten. Höhere Leistung schlägt in der Regel können Sie dickeres Produkt zu reduzieren.

Ein Gerät, das z. B. 30 mm dicken Kohlenstoffstahl mit ausreichender Leistung schneiden kann, ist wichtig, wenn Sie schwere Arbeiten ausführen. Wenn Sie hauptsächlich mit dünnen Blechen arbeiten, könnte ein Gerät mit geringerer Leistung perfekt sein. Das Wichtigste ist, dass Sie ein Gerät mit der idealen Leistung für die Produkte finden, die Sie häufig bearbeiten. Diese Fähigkeit garantiert, dass Sie nicht durch die Produktdichte eines Auftrags eingeschränkt sind.

Qualität schneidet: Der letzte Schliff

Raue Seiten, Schlacke und Wärmeverzug? Nein, vielen Dank. Faserlaser sind dafür bekannt, dass sie einen wirklich sauberen Schnitt liefern. Wir sprechen von glatten Seiten, die in der Regel viel weniger Aufräumarbeiten erfordern.

Hervorragende Schnittqualität spart Ihnen Zeit und Arbeit beim Schleifen und Nachbearbeiten. Die Teile sehen nach der Bearbeitung gut aus und sind bereit für die nächste Aktion. Für alles, was ein ordentliches Aussehen oder eine gute Passform haben muss, ist dies entscheidend. Die Lieferanten konzentrieren sich auf Dinge wie die Spitzenqualität des Lichtstrahls und die Schneidkopftechnologie, um sicherzustellen, dass Sie jederzeit eine hervorragende Oberfläche erhalten.

Seriöse Ausrüstungen, verlässliche Organisation

Machen wir uns nichts vor: Wenn Ihr Gerät ausfällt, verlieren Sie Geld. Punkt. Deshalb sind Langlebigkeit und Verlässlichkeit so wichtig. Sie wollen ein Gerät, das aus hochwertigen Elementen besteht und den täglichen Anforderungen in einem geschäftigen Betrieb gewachsen ist.

Suchen Sie nach Herstellern, die hervorragende Komponenten verwenden und ein solides Gebäude haben. Integrität bedeutet regelmäßige Leistung, nicht nur das Vermeiden von Pannen. Ausfallzeiten sind teuer, daher ist es klug, in einen Maker zu investieren, der so konstruiert ist, dass er lange hält und jeden Tag funktioniert. Das bedeutet weniger Migräne und mehr Zeit zum Schneiden.

Die Ortung Ihres Begleiters: Schauen Sie in BOGONG Laser

Okay, Sie wissen also, was einen Faserlaserschneider auszeichnet. Aber wo finden Sie jetzt einen? Das ist der Punkt, an dem die Auswahl des idealen Herstellers ins Spiel kommt. Sie benötigen einen Partner, der die Art von Geräten verwendet, über die wir gesprochen haben - Maschinen, die schnell, genau, vielseitig und robust gebaut sind.

Bogong Laser ist ein Hersteller, der Maschinen zum Schneiden von Stahl mit Faserlasern anbietet, die mit Blick auf diese wesentlichen Vorteile entwickelt wurden. Das Unternehmen kennt die Schwierigkeiten, mit denen Metallbauer täglich konfrontiert sind - die Anforderung an Geschwindigkeit, Präzision und die Fähigkeit, verschiedene Aufträge zu bewältigen.

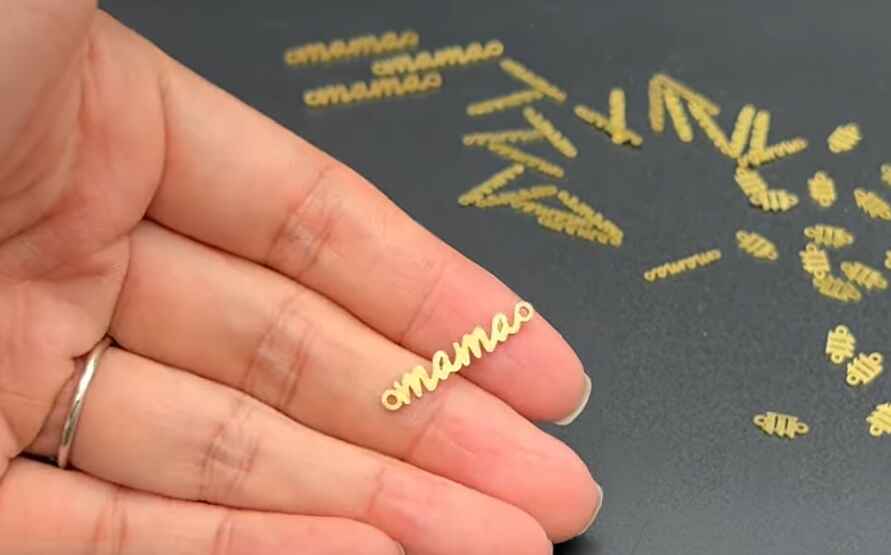

Sie bieten eine Reihe von Geräten für unterschiedliche Anforderungen. Wenn Sie sowohl mit Stahlblechen als auch mit Rohren zu tun haben, ist so etwas wie ihre Laserplatte & Rohr Combo Faserlaser-Reduziermaschine könnte genau das sein, was Sie brauchen. Wenn Sie sich um große Mengen an dicken Produkten kümmern, sind ihre 6000W-40KW Faserlaserschneidmaschine könnte der Muskel sein, den Sie brauchen. Für kleinere, tiefer gehende Arbeiten oder bestimmte Anwendungen wie die Bearbeitung von Messing, Gold oder Silber gibt es Alternativen wie die Kleinste Faserlaserschneidmaschine. Sie können ihr komplettes Angebot entdecken, einschließlich ihrer wichtigsten Faserlaser-Metallschneider Auf der Website können Sie die Spezifikationen einsehen und herausfinden, welches Gerät am besten zu Ihrem Verfahren passt.

Bei der Auswahl des besten Anbieters geht es nicht nur um die Geräte selbst. Es geht auch darum, dass Sie wissen, dass der Hersteller sein Produkt unterstützt und Ihnen hilft, wenn Sie es brauchen. Ein guter Hersteller ist ein Partner für Ihr Unternehmen.

Allzeit-Tiefststand

Erlangung eines Faserlaser-Metallschneider ist ein großer Schritt, aber einer, der sich wirklich auszahlen kann. Es geht darum, die Produktionsrate zu erhöhen, um mehr Teile herstellen zu können, die Genauigkeit zu verbessern, um den Ausschuss zu verringern und die Qualität zu steigern, und die Vielseitigkeit zu gewinnen, um mehr Arten von Aufgaben zu bewältigen. All dies führt zu niedrigeren Preisen, höheren Einnahmen und einem erschwinglichen Unternehmen.

Die Entdeckung eines Herstellers wie Bogong Laser der Maschinen mit diesen Fähigkeiten einsetzt und weiß, was Sie brauchen, ist entscheidend. Es handelt sich um eine Investition in Technologie, die Ihr Unternehmen voranbringen kann, indem sie Ihnen hilft, Ihre Probleme zu lösen und ganz neue Chancen zu eröffnen. Es geht darum, das beste Gerät für die jeweilige Aufgabe zu bekommen, damit Sie Metall schneller, besser und rentabler schneiden können.