-

Shunhua Road, Jinan City, Shandong

Beste 3 in 1 Laserschweiß-, Reinigungs- und Schneidmaschine Hersteller

BOGONG Laser ist der vertrauenswürdige Hersteller von 3D-UV-Lasermarkierungs- und 3-in-1-Laserschweißmaschinen und bietet präzise, vielseitige Lösungen mit Großhandelsoptionen.

Gut, lassen Sie uns über das Geschäft sprechen. Wenn Sie in der Stahlbaubranche tätig sind, wissen Sie, dass Zeit bares Geld ist und dass Spitzenqualität das A und O ist. Zwischen Schweißern, Fräsern und Schneidegeräten hin- und herwechseln? Das ist mühsam. Was wäre, wenn Sie all das in einem einzigen Gerät unterbringen könnten? Das ist der Punkt, an dem die Rede von 3-in-1-Laserschweiß-, Reinigungs- und Schneidgeräten ist. Und wenn Sie auf der Suche nach einem Top-Lieferanten sind, müssen Sie genau wissen, wie diese Maschinen Ihren Prozess völlig umkrempeln können.

Was hat es also mit dem "Besten 3 in 1 Laserschweiß-, Reinigungs- und Schneidmaschinenhersteller" auf sich?

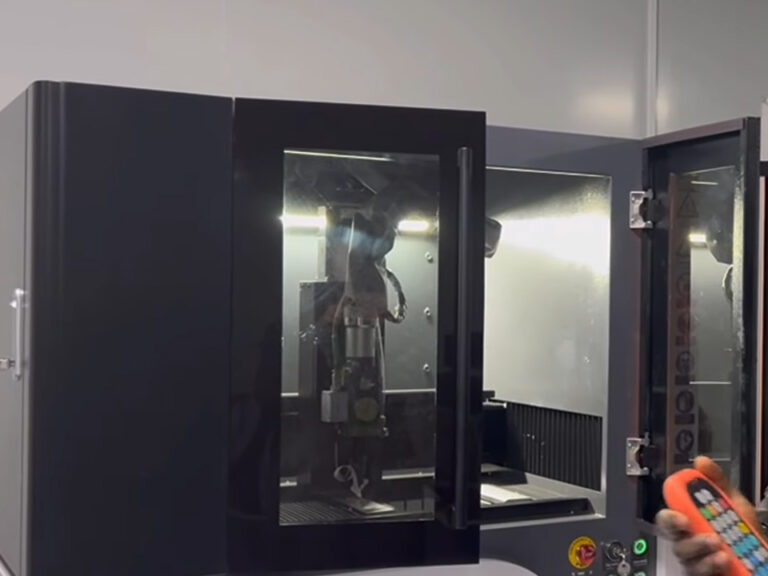

Denken Sie darüber nach: eine Stromquelle, ein Kontrollsystem, ein tragbares Gerät, das die Aufgabe von drei Geräten erfüllt. Diese Kombination ist der Schlüssel. Wir sprechen hier nicht einfach von drei Herstellern, die miteinander verschraubt werden. Die besten Spieler, wie BOGONG Laser, entwickeln diese Systeme von Grund auf neu.

Warum Sie sich einen 3-in-1-Lasermacher in Ihrem Team wünschen

Lassen Sie uns aufschlüsseln, warum diese Geräte ein so heißes Thema sind und wie genau ein Qualitätshersteller den Unterschied macht.

1. Ultimative Bequemlichkeit: Eine Maschine, viele Hüte

Die alte Methode: Sie haben Ihr WIG-Schweißgerät für exakte Aufgaben, möglicherweise ein MIG-Gerät für die Geschwindigkeit, eine Winkelfräse für die Reinigung und ein Plasmaschneidgerät oder eine Schere zum Schneiden. Das ist eine Menge Ausrüstung, eine Menge Platz und eine Menge Zeit, die Sie in das Umschalten von Aufgaben investieren müssen.

Die 3-in-1-Lösung: Sie erhalten ein Gerät, das alles kann. Sie müssen eine Verbindung aus rostfreiem Stahl verkleben? Erledigt. Sie haben etwas Rost oder alte Farbe zu entfernen, bevor Sie beginnen? Wechseln Sie zum Reinigungsgerät. Müssen Sie eine Kante schneiden oder eine maßgeschneiderte Form aus einem dünnen Blech schneiden?

Wechseln Sie zum Schneiden. Dies ist ein bedeutender Vorteil für maßgeschneiderte Fab-Läden, Reparaturservice-Lösungen oder jede Art von Geschäft, in dem Sie ständig mit verschiedenen Aufgaben konfrontiert sind. Zum Beispiel, BOGONG Laser's 3-in-1-Handlaserschweißgerät ist genau für diese Art von Anpassungsfähigkeit gemacht und bietet verschiedene Leistungsoptionen (von 1000W bis 3000W), um Ihren Anforderungen gerecht zu werden.

Effizienz steigern und einfach halten

Schmerzpunkt: Ausfallzeiten, die durch den Materialtransport zwischen den Stationen oder das Einrichten verschiedener Maschinen entstehen, beeinträchtigen Ihre Produktivität. Auch die Schulung der Mitarbeiter an mehreren komplexen Maschinen kostet Zeit und Ressourcen.

Die Lösung: Bei einem 3-in-1-Gerät kann das Werkstück oft an Ort und Stelle bleiben, während Sie die Funktionen des Handgerätes wechseln. Moderne Geräte, wie die von BOGONG Laser, verfügen über benutzerfreundliche Schnittstellen - oft einen Touchscreen -, auf denen Sie schnell das Verfahren auswählen und die Parameter einstellen können. Die handgeführten Laserpistolen sind leicht und ergonomisch, was bedeutet, dass der Bediener weniger ermüdet und schwierige Stellen leichter zu erreichen sind. Denken Sie an die Zeitersparnis bei einer Arbeit mit komplexen Informationen, wie z. B. bei der Herstellung von maßgeschneiderten Kochfeldabzugshauben oder detaillierter Metallkunst, bei der Sie vielleicht schweißen, eine Fuge reinigen und danach eine Kante schneiden müssen, und das alles in schneller Folge.

Schweißen der Extraklasse

Schmerzpunkt: Traditionelles Schweißen kann schwierig sein. Ein tiefes Eindringen ohne Hinterschneidungen zu erreichen, lästige Poren oder Risse zu vermeiden und dann ewig lange damit zu verbringen, hässliche Schweißnähte abzuschleifen? Das ist ein Kampf. Verzug bei dünneren Materialien bereitet ebenfalls Kopfzerbrechen.

Laser-Präzision: Das Faserlaserschweißen, das Herzstück dieser 3-in-1-Maschinen, ist ein echter Wendepunkt. Sie erhalten unglaublich präzise, starke Schweißnähte mit minimaler Wärmezufuhr. Das bedeutet eine winzige Wärmeeinflusszone (HAZ), also weniger Verzug und weniger Belastung für das Material. Die Schweißnaht ist oft so glatt und sauber, dass BOGONG Laser feststellt, dass ihre Maschine Schweißnähte erzeugt, die "keine Schweißspuren, keine Verfärbungen und kein späteres Polieren erfordern". Das spart eine Menge Nachbearbeitungszeit und Verbrauchsmaterial wie Schleifscheiben. Stellen Sie sich vor, Sie schweißen empfindlichen Edelstahl für lebensmitteltaugliche Geräte oder komplizierte Aluminiumteile für die Elektronik - die Präzision und die geringe Hitze sind von unschätzbarem Wert.

Reinigungskraft: Umweltfreundlich und schnell

Schmerzpunkt: Chemische Reinigung ist schmutzig, beinhaltet gefährliche Stoffe und die Entsorgung ist mühsam. Beim Sandstrahlen entsteht eine Menge Staub. Schleifen oder Drahtbürsten ist langsam und arbeitsintensiv.

Laser Clean: Die Laserreinigung ist ein berührungsloses Verfahren. Es nutzt den fokussierten Laserstrahl, um Rost, Farbe, Oxide, Öle und andere Verunreinigungen direkt von der Oberfläche zu verdampfen, ohne den Untergrund zu beschädigen. Es gibt keine Chemikalien, keine Schleifmittel, und der Abfall ist in der Regel ein feines Pulver, das sich leicht auffangen lässt. Die Maschinen von BOGONG Laser können die Reinigung vor dem Schweißen übernehmen, um eine perfekte Oberfläche für eine starke Verbindung zu gewährleisten, oder die Reinigung nach dem Schweißen, falls dies erforderlich ist (obwohl das oft nicht der Fall ist!). Dies ist ideal für Restaurierungsarbeiten, die Reinigung von Schimmelpilzen oder einfach nur für die Vorbereitung von Oberflächen, die schnell, sauber und umweltfreundlich ist.

Schneiden: Schnelle Schnitte für leichtere Arbeiten

Der Deal: Diese Maschinen ersetzen zwar nicht Ihre Hochleistungs-Plasma- oder Faserlaser-Schneidtische für dicke Bleche, aber die Schneidfunktion eines 3-in-1 ist sehr praktisch für dünne Bleche (z. B. Edelstahl, Kohlenstoffstahl, Aluminium bis zu einigen Millimetern, je nach Laserleistung).

Der Anwendungsfall: Müssen Sie schnell eine benutzerdefinierte Halterung schneiden, eine Kante zuschneiden oder eine präzise Öffnung in einer dünnen Platte anbringen? Die Laserschneidfunktion ist perfekt. Sie ist schnell, genau und bietet einen sauberen Schnitt mit minimaler Krätze. Für Unternehmen, die kundenspezifische Gehäuse, Beschilderungen oder detaillierte dekorative Teile aus Blech herstellen, ist diese integrierte Schneidefunktion ein echter Vorteil.

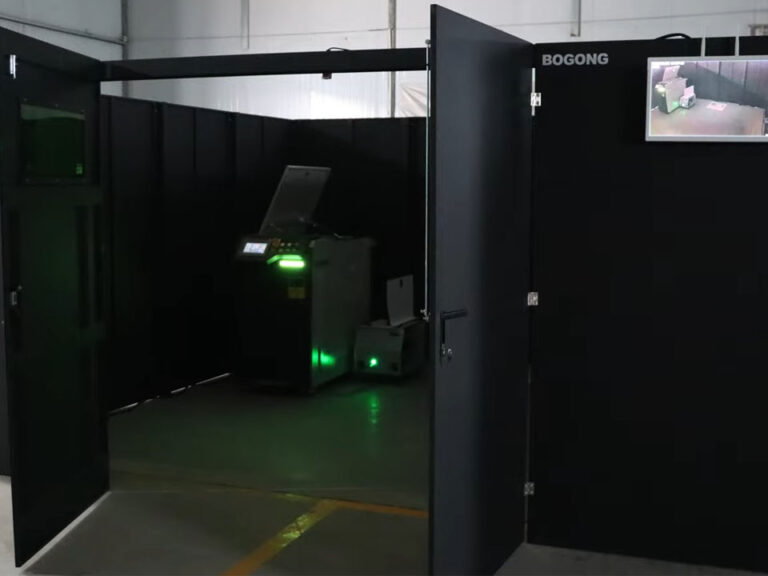

BOGONG Laser im Blickpunkt: Warum sie in der Diskussion um den besten Hersteller" sind

Sie denken also: "Diese 3-in-1-Technologie scheint fantastisch zu sein, aber auf wen kann ich mich verlassen?" Hier ist ein Unternehmen wie BOGONG-Laser betritt das Bild. Sie sind nicht einfach nur Wiederverkäufer; sie sind tief mit dem Design und den Fähigkeiten ihrer Geräte verbunden. Die 3-in-1-Handlaserschweißgerät ist ein Musterbeispiel dafür, wie diese flexible Innovation in ein robustes, benutzerorientiertes System integriert werden kann.

Sie liefern eine Auswahl an angesehenen Laserquellen (wie Raycus, MAX, JPT, IPG), was bedeutet, dass Sie das Gerät auf Ihre Leistungsanforderungen und Ihren Finanzplan abstimmen können. Dieses Interesse an der Spitzenqualität der Komponenten ist ein Merkmal eines großen Herstellers.

Real-World Wins: Wo der 3-in-1 von BOGONG Laser funkelt

Stellen wir uns ein paar Umstände vor:

Der Customized Car Store: Stellen Sie sich eine Werkstatt vor, die einen Oldtimer restauriert. Sie müssen verrostete Bleche reparieren (Laserreinigung), brandneue Punktteile mit sehr wenig Biegung einschweißen (Laserschweißen) und danach vielleicht eine personalisierte Strebe schneiden (Laserschneiden). Anstelle von 3 Konfigurationen schafft eine einzige BOGONG-Lasermaschine alles, was Stunden spart und die Qualität der Sanierung verbessert.

Der Hersteller von Küchengeräten: Nichtrostender Stahl ist hier das Maß aller Dinge. Das Schweißen von rostfreiem Edelstahl für Spülen, Küchentheken und Geräte muss sauber, stabil und verzugsfrei sein. Die Fähigkeit, eine optimale, glatte Schweißnaht zu erhalten, die nicht mehr nachgearbeitet werden muss, ist ein großer Preis- und Zeitvorteil. Das Vorreinigen von Ölrückständen mit dem Laser vor dem Schweißen sorgt für perfekte Verbindungen.

Die winzige Kunsthandwerkerwerkstatt: Ein Metallkünstler, der detaillierte Skulpturen oder individuelle Schilder herstellt, kann den BOGONG 3-in-1 nutzen, um zerbrechliche Teile zu schweißen, Wärmetönungen oder Oberflächenverunreinigungen auszubessern und umfassende Formen aus dünnen Stahlblechen präzise zu schneiden. Die einfache Handhabung und die Vielseitigkeit ermöglichen eine noch größere kreative Flexibilität und einen schnelleren Abschluss der Arbeit.

Die Frustrationen in der Werkstatt bewältigen

Denken Sie an diese häufige Migräne. Ein hochwertiges 3-in-1-Gerät, wie das von BOGONG Laser, nutzt ein direktes Heilmittel:

- "Sind Sie es leid, mehrere Geräte für eine Arbeit zu verwalten?" Der 3-in-1 kombiniert Ihren Prozess.

- "Schleifen und Polieren nach dem Schweißen, das sich direkt auf Ihre Einnahmen auswirkt?" Beim Laserschweißen wird in der Regel eine fertige Naht erzeugt.

- "Haben Sie Probleme mit Materialverzug, besonders bei dünnem Material?" Durch die geringere Wärmeeinbringung beim Laserschweißen wird dies verringert.

- "Chemische Reinigung zu langsam, unsauber und teuer?" Die Laserreinigung ist schnell, sauber und benötigt keine Verbrauchsmaterialien.

- "Müssen Sie schnelle, präzise Schnitte an Stahlblechen durchführen, ohne dass eine bestimmte Konfiguration erforderlich ist?" Mit der Schneidefunktion sind Sie bestens gerüstet.

Real-World Wins: Wo der 3-in-1 von BOGONG Laser glänzt

Damit Sie sich ein besseres Bild machen können, hier eine Übersicht darüber, was Sie normalerweise mit einem BOGONG Laser 3-in-1-System erhalten:

Warum auf BOGONG Laser setzen?

Bei der Auswahl eines Herstellers geht es nicht nur um den Hersteller, sondern um die Zusammenarbeit. BOGONG Laser legt nicht nur Wert auf die technischen Spezifikationen, sondern auch auf eine sinnvolle Anwendung und Unterstützung. Wenn Sie Geräte kaufen, die Ihre Produktion neu definieren können, wollen Sie einen Anbieter, der Ihre Hindernisse versteht und Unterstützung bieten kann. Erkundung ihrer vollständige Reihe von Dienstleistungen können Sie sich ein weitaus besseres Bild von ihrem Engagement im Lasersektor machen.

Allzeit-Tiefststand

Wenn Sie besonders wettbewerbsfähig und effizient sein und eine höhere Arbeitsqualität erreichen wollen, ist ein 3-in-1-Laserschweiß-, Reinigungs- und Reduziermaschine ist ein bedeutender Anwärter für Ihre nächste Werkzeugaufrüstung. Und wenn Sie auf der Suche nach dem "idealen 3 in 1 Laserschweißreinigungs- und -reduziermaschinenhersteller" sind, müssen Sie nach Unternehmen suchen, die robuste moderne Technologie, Vielseitigkeit und ein klares Verständnis dafür bieten, was Stahlhersteller wirklich brauchen.

BOGONG Laser hat sich in diesem Bereich stark positioniert und liefert ein vielseitiges Werkzeug, das eine Reihe von Unannehmlichkeiten in der modernen Metallbearbeitung beseitigt. Sie fügen nicht einfach einen weiteren Hersteller hinzu, sondern eine neue Ebene von Fähigkeiten. Sind Sie bereit zu sehen, wie es in Ihr Geschäft passen könnte? Es könnte an der Zeit sein, Kontakt aufzunehmen mit BOGONG-Laser und informieren Sie sich über die Besonderheiten Ihrer individuellen Anforderungen.