-

Shunhua Road, město Jinan, Shandong

Procurement of Laser Cutting Machines for Data Center Rack Manufacturing

Discover how to choose the right laser cutting machines for data center rack production—maximize precision, automation, and cost-efficiency in your operation.

To successfully acquire laser cutting machines for data facility shelf production, concentrate on lining up equipment abilities with manufacturing demands, making sure product compatibility, and prioritizing automation for performance. Think about elements like laser power, reducing rate, material thickness, and automation functions when selecting an equipment.

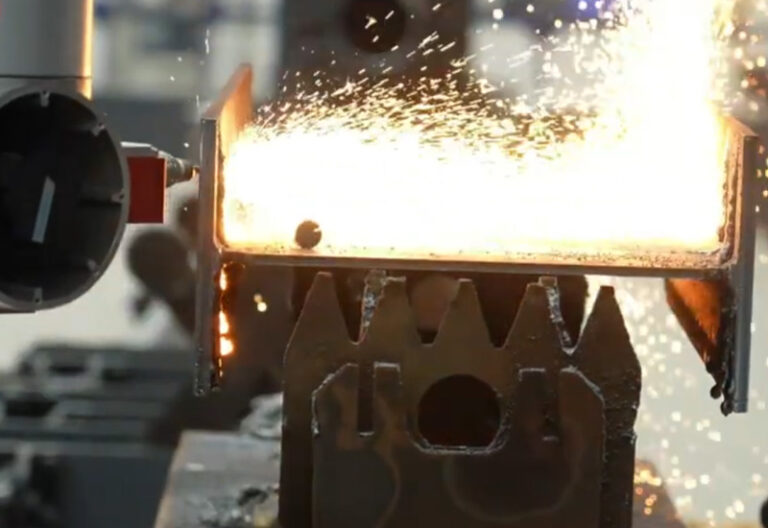

Why Laser Cutting Machines Are the Backbone of Data Center Rack Manufacture

When it pertains to building data center racks, precision isn’t simply great to have– it’s non-negotiable. Every hole, every joint, and every edge has to align perfectly to handle airflow, thermal management, and the crazy weight of servers. That’s where Laserové řezací stroje step up. They’re not just cutting tools—they’re the heart of the whole metalworking process.

For manufacturers dealing with sheet metal or tubular steel racks, a reliable Laser Cutting Machine makes or breaks efficiency. And if you’re hunting for a partner with a global reach and serious manufacturing pedigree, BOGONG LASER®, a seasoned Výrobce laserových řezacích strojů, has been supplying OEM/ODM-ready machines in over 160 countries with ISO, CE, and FDA certifications.

Fiber vs. CO₂: Why Fiber Laser Cutting Wins for Racks

For data centers, the rack frames are often made from cold-rolled steel or aluminum. These metals respond better to fiber lasers, offering tighter tolerances and cleaner cuts. So unless you’re cutting acrylic or wood, fiber’s the better pick. The following data will better illustrate why:

| Funkce | Fiber Laser Cutting | CO₂ Laser Cutting |

|---|---|---|

| Cutting Speed (especially on metal) | Fast – great for stainless, carbon steel | Slower and less efficient |

| Údržba | Minimální | Frequent (mirrors, optics) |

| Spotřeba energie | Lower | Higher |

| Operating Costs | Lower over time | Higher due to parts |

| Suitable for Metals | Yes (especially fine detail work) | Less ideal |

Want a quick visual breakdown of this comparison? Check out this short video:

Fiber & CO2 Laser Cutting Machine | BOGONG 1313 Pro Cutting Metal / Wood/ Acrylic etc

Why Automation Matters

Ever had a cutting machine idle while workers loaded raw material manually? That downtime’s a money pit.

Here’s how automated systems help:

Automatic loading/unloading keeps machines working nonstop.

Integrated material storage shortens response time during job changes.

Smart sensors prevent collisions or misfeeds (common when feeding longer tubes or plates).

If you’re cutting thousands of holes in tube frames for server racks, BOGONG’s Automatické načítání laserového řezacího stroje na trubky could upgrade to your ops. Pairing smart automation with laser precision saves both labor cost and production time.

Total Cost of Ownership: Look Past the Price Tag

Many buyers get tripped up focusing on the sticker price. But here’s the deal—you need to look at Celkové náklady na vlastnictví (TCO).

| Cost Element | Description |

|---|---|

| Initial Machine Cost | The base price, but it’s only part of the picture |

| Spotřeba energie | Fiber uses less power, meaning lower bills long term |

| Maintenance + Downtime | Frequent part swaps? Say goodbye to uptime |

| Operator Efficiency | One skilled operator can run multiple smart machines |

| Software Upgrades | Built-in nesting, cloud support = less scrap waste |

One client in the metal rack business told us they slashed 30% off their production cost—not from buying a cheaper machine—but from cutting downtime, training, and scrap material. BOGONG helps clients evaluate not just which machine fits, but how it’ll actually perform under real-world factory conditions.

Precision Matters: Tolerances and Thermal Load

Let’s get into the weeds for a sec. Why are tight tolerances so critical in data center racks?

Airflow: Misaligned holes or brackets can trap hot air = overheating.

Weight-bearing: Bad welds or poor cuts can stress frame integrity.

Expansion tolerance: Racks expand when hot—your cuts need to accommodate that.

Laser cutting helps you hit those tight tolerances without post-processing. Machines like BOGONG’s Kuželový laserový řezací stroj are built for tricky corners, edge chamfering, and bevel cuts in one go—so you don’t need a secondary grinding or milling step. This isn’t just cleaner—it’s faster and cheaper.

Modularity in Manufacturing

Data centers grow fast, and their racks need to scale with them. That’s why your cutting machine setup should be modular.

Cut sheets AND tubes? Use a combo machine like Laserový řezací stroj na desky a trubky Fiber Laser Combo.

Work with limited floor space? Na stránkách Nejmenší 3020 Fiber Laer řezací stroj nebo 5050 Vláknový laserový řezací stroj gives you compact power.

No two rack designs are exactly the same. Some are deeper, some carry heavier servers, and others need extra ventilation slots. You want a system that doesn’t freak out when your CAD file changes.

Multiple Machines, Redundant Systems: The Reliability Factor

If you’re running 24/7 manufacturing or need short lead times, relying on just one machine’s risky. Downtime kills delivery schedules. That’s why many manufacturers go for machine clusters.

This setup gives you:

Redundancy (if one goes down, the others pick up slack)

Parallel production (run different jobs simultaneously)

Easier maintenance rotation

BOGONG’s clients often stagger different models, like one high-power model for thick steel and a smaller unit for thin aluminum. It’s not about size—it’s about building resilience into your ops.

Global Reach, Local Service: What Sets BOGONG Apart

BOGONG LASER® isn’t new to this game. With machines sold in 160+ countries and 9,000+ clients worldwide, our focus isn’t just on building great tools—it’s on keeping your production running.

Multilingual support? Check.

OEM/ODM options? Ready.

Certifications like CE, FDA, SGS? All covered.

Our factory-built machines—from large-format cutters to compact tabletop units—fit into factories of every size. Whether you’re a metal shop looking to expand or an integrator building high-volume rack systems, BOGONG’s catalog can slot right in.

Ready to Start?

Want to know which machine fits your data center rack line? Fill out the BOGONG Laser contact form—let’s build something precise, powerful, and future-proof.