-

Shunhua Road, město Jinan, Shandong

OEM ODM Laser Cutting Machine Solution for Sports Equipment

Enhance sports equipment production with OEM ODM Laser Cutting Machine solutions from BOGONG Laser. Get precise cutting, seamless automation.

Laserové řezací stroje offer a versatile solution for producing sports equipment, with OEM/ODM services providing customized and efficient manufacturing options. These machines can handle various materials like metal tubes, sheets, and even some plastics, enabling the creation of a wide range of equipment components.

High‑Speed, High‑Precision Cutting for Sports Gear Materials

You’ve got carbon‑fiber bike frames, aluminum rails, even layered composites. Each needs a clean, burr‑free finish right off the laser head—no sanding or secondary ops. A top‑tier Řezací stroj s vláknovým laserem nails ±0.02 mm repeatability. That kind of repeatable accuracy cuts scrap rates, shrinks rework time, and keeps your takt time lean. Plus, auto‑focus tech and CNC nesting optimize material use—so you’re not tossing half‑cut blanks into the bin. It’s all about consistency: one cycle per sheet, every single time.

Automation Advantages in Fitness Equipments Manufacturing

Manual loading slows you down and introduces errors. BOGONG Laser’s Automatické načítání laserového řezacího stroje na trubky tackles that. Toss in a batch of pre‑cut tubes, hit start, and walk away. The machine auto‑feeds, clamps, cuts, and unloads. You’ll see uptime climb while your crew focuses on higher‑value tasks. In a treadmill frame run, for example, you eliminate misfeeds that cause head collisions and wasted parts.

Clean‑Edge Apparel Cutting Scenarios

Sports apparel needs crisp lines and no fraying. Enter CO₂ lasers. With a Laserový gravírovací stroj CO2, you get edge‑seal on fabrics like polyester spandex blends. That micro‑melt finish stops threads from popping, so you don’t need extra hemming. For a custom jersey line, you can swap patterns in seconds, cue the file, and run through a dozen designs without changing tooling. That’s die‑less cutting—fast prototyping plus on‑demand small batches. It’s all about flexibility in your production flow.

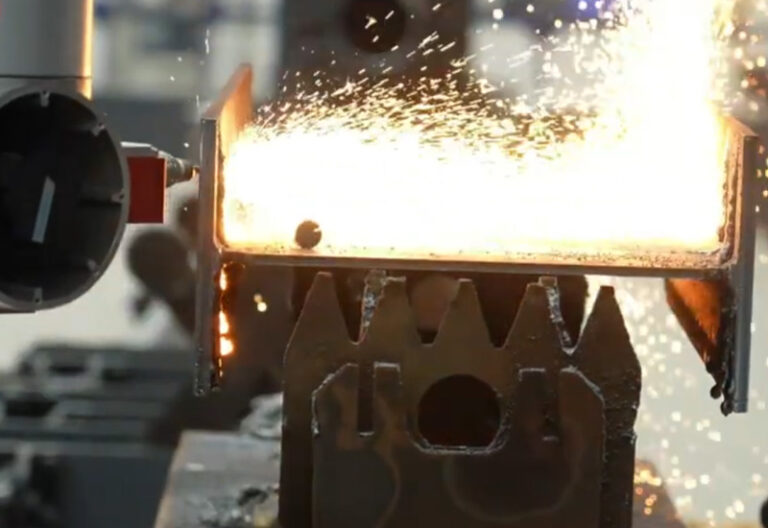

Advanced Tube Processing for Frames & Racks

Dumbbell handles, pull‑up bar sections, bike forks—they all come from rounds, squares, or D‑shaped tubes. A three‑jaw chuck system grips odd profiles firmly. With a Kuželový laserový řezací stroj, you can cut and chamfer in one go. The head tilts for perfect miters, meaning welded joints sit flush with zero gaps. No more sticky fixtures or custom jigs. You’ll cut weld prep time and improve joint quality—big win for any OEM ODM Laser Cutting Machine Factory aiming to impress.

Material Versatility Across Metal & Composite

Sports tech evolves fast. One day it’s titanium bike stems; next, it’s hybrid polymer‑metal composites for smart helmets. You need a system that handles both. The Laserový řezací stroj na desky a trubky Fiber Laser Combo lets you flip from sheet to tube workflows without swapping gear. It’s an all‑in‑one solution that tackles metal sheets, round bars, and profiles. That versatility keeps your line nimble. No bottlenecks when a new trend hits the market.

Smart Controls That Slash Downtime

BOGONG Laser’s UI packs job memories, auto‑alignment prompts, and live diagnostic feeds. Hit a one‑touch recall, and the system repositions lenses, re‑zeros datum points, and checks beam stability. You don’t waste hours on trial cuts. And if there’s an alignment error or gas‑pressure dip, the controller flags it instantly. That kind of real‑time feedback slashes lost‑time incidents and keeps maintenance on schedule.

Summary Table of Core Benefits

| Funkce | Benefit | Scénář |

|---|---|---|

| Auto‑Feeding Tube System | Zero manual touch, higher uptime | Treadmill frame batch runs |

| Burr‑Free Edge Finish | No secondary sanding or polishing | Carbon‑fiber bike panels |

| Multi‑Material Flexibility | Switch from metal to composite easily | Helmet prototype trials |

| Die‑less Fabric Cutting | No fraying, instant style changes | Custom sports jersey runs |

| CNC Job Memory & Diagnostics | Rapid changeover, minimal trial cuts | Daily small‑batch runs |

This table sums it up: you get less waste, fewer stops, and cleaner parts—exactly what any Laser Cutting Machine Manufacturer should promise.

Final Thoughts & Next Steps

Working with a true partner moves the needle. BOGONG Laser isn’t just a supplier—it’s a collaborator. In the fast‑paced world of sports equipment, you can’t settle for generic tools. Your end users demand top performance and flawless finish. OEM ODM Laser Cutting Machine solutions from BOGONG Laser give you precision, speed, and flexibility—backed by global support and certifications (CE, ISO9001, SGS, FDA). Ready to upgrade your line? Check out our Laser Cutting Machine range, fill out the contact form, and let’s get your next project rolling.

Welcome to drop your contact info via the BOGONG form—our team will get back to you ASAP!