What is a UV Laser?

To create a UV laser, the process involves the laser beam passing through two additional crystals, which is different with standard fiber laser systems. First, a standard wavelength laser (1064 nm) is directed through a nonlinear crystal, which reduces the wavelength to 532 nm. Then, this light goes through another crystal, further decreasing the wavelength to 355 nm. That’s why UV lasers are often referred to as third-harmonic generation (THG) lasers, since they produce this third wavelength. The marking done with these lasers is known as “Cold Marking,” highlighting their ability to mark and process materials with very little heat, minimizing any potential damage.

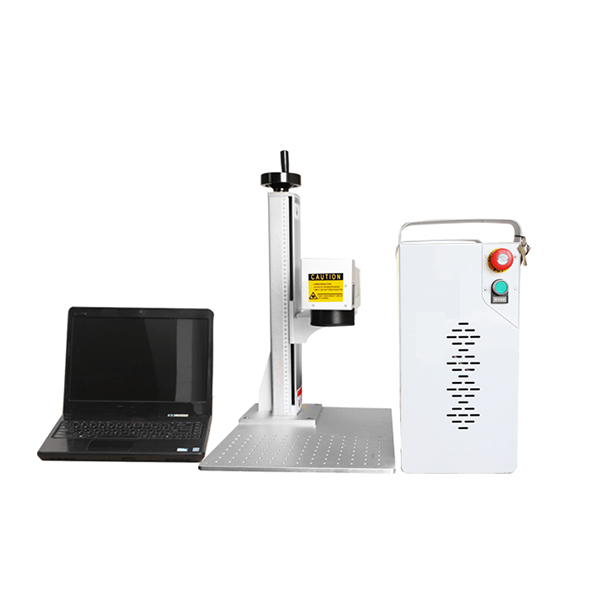

Features of UV Laser Marking Machine

High Contrast Marking

Compared to standard laser light at 1064 nm and green laser light at 532 nm, UV laser light has a much higher absorption rate for materials. This higher absorption allows for more visible marks with less power, resulting in damage-free markings. Because of this, UV laser marking machines can effectively handle challenging materials like plastics, highly reflective metals, and heat-sensitive substances.For example, UV laser marking machines are commonly used in product identification, medical device manufacturing, and aerospace components, where heat damage from traditional lasers is unacceptable. They are also effective on various types of plastics, including colored ones that are difficult or even impossible to mark with fiber lasers.

More Applicaiton

UV lasers use a wavelength of 355 nm, which is much shorter than that of fiber laser marking systems. This shorter wavelength allows materials to absorb the light more effectively. One major benefit of UV lasers is their ability to perform “cold marking.” This method breaks material bonds through photolytic processing, creating contrast or removing material without generating much heat.Standard lasers heat the material until its bonds break. This process often creates a heat-affected zone (HAZ) around the mark. The HAZ can change material properties, leading to damage or increased scrap.UV lasers eliminate the risk of a heat-affected zone, producing marks that are surface-level yet permanent. They are ideal for a variety of materials, including plastics, resins, glass, rubber, ceramics, and metals, especially when surface finish and material integrity are concerns.

UV laser engraving machines can mark a wide range of materials, including:

– Plastics: Suitable for marking a variety of plastics such as acrylic, polyethylene, polyvinyl chloride (PVC), and nylon.

– Metals: Capable of surface marking on specific metal types.

– Wood: Can mark almost any type of wood, including walnut, oak, maple, birch, plywood, cherry, and fiberboard.

– Glass: Engraves glass without breaking or splintering.

– Paper: Effectively cuts and marks paper and cardboard, producing clear contrasts.

Damage-Free Marking & Processin-

Why is a UV laser marking machine the best option for these applications? The primary reason is its exceptionally high absorption rate across a range of materials. This leads to marking and processing with minimal heat stress, which reduces surface damage and enables corrosion-resistant markings. These qualities help protect materials and components from issues during the marking and manufacturing process.

Advantage of UV Laser:

- Increased Productivity: With no consumables to replace, operation remains uninterrupted, allowing production lines to run longer.

- Maximized Availability: The air-cooled laser source significantly reduces unscheduled downtime, ensuring the laser is always ready for use.

- Less Maintenance: Daily mechanical maintenance procedures are eliminated, further boosting uptime.

Engineered for High Performance:

- Efficient Marking: The UV wavelength facilitates high-speed marking-on-the-fly of HDPE/LDPE packaging, improving overall efficiency.

- Quality Marks: Create vision-readable 2D codes at speeds of up to 5.0 m/sec.

- Consistent Quality: The 360° Arc Compensation Software ensures high-quality marks on rotational devices, minimizing distortion.

- High Contrast: Achieve repeatable, high-contrast color changes for optimal vision readability on white HDPE/LDPE.

Our UV Laser Software

BOGONG use Ezcad softare, this program is equipped with many advanced features

- Easy installation on computer.

- Operational safety.

- User-friendly interface.

BOGONG Also provide UV laser marking machine with water cooling, contact with us for more detail.

Which Parts is optional with UV laser machine

- Поворотний пристрій: є кілька поворотних пристроїв з різним стилем і діаметром затискача, наприклад, 50D 65D 80D

- Special rotary for Bottle.

- Conveyor

Payment Terms for the UV laser engraver

1. Депозит і баланс: Депозит 30% T/T необхідно внести заздалегідь, а залишок сплатити перед відправкою.

2. Alibaba Trade Assurance: Платежі можуть бути оброблені через Alibaba Trade Assurance.

FAQs

What Is the Packaging for the UV Laser Marking Machine?

Наші машини пакуються у тришарову упаковку. Зовнішній шар складається з дерев'яного ящика, середній шар має пінопластову прокладку для захисту від тряски, а внутрішній шар включає товстий поліетиленовий пакет для гідроізоляції.

Чи не пошкодиться пакунок під час транспортування?

Ми ретельно розробляємо упаковку, щоб врахувати всі потенційні фактори пошкодження, а наші транспортні агенти мають досвід безпечного транспортування. Ми успішно експортуємо у 180 країн світу, тому ви можете бути впевнені, що ваша посилка прибуде у відмінному стані.

Більшість клієнтів люблять вибирати транспорт UPS / DHL експрес, він може прибути в пункт призначення приблизно через 5-7 днів, зв'яжіться з BOGONG, щоб отримати більш детальну інформацію про волоконний лазерний гравер по металу для срібла, латуні, золота і міді.