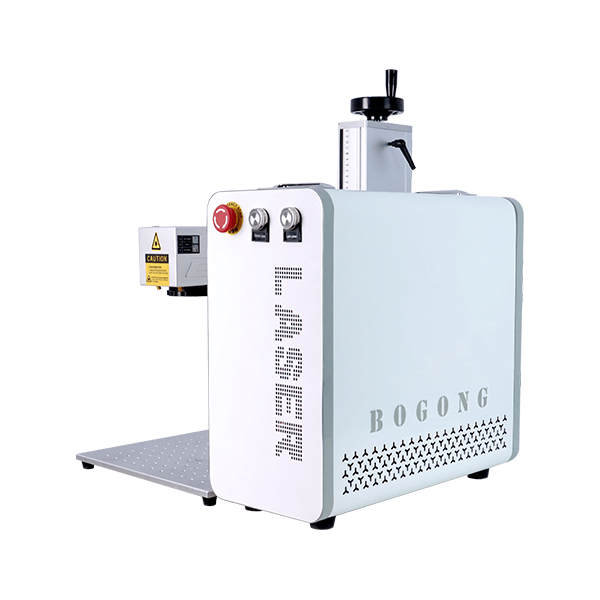

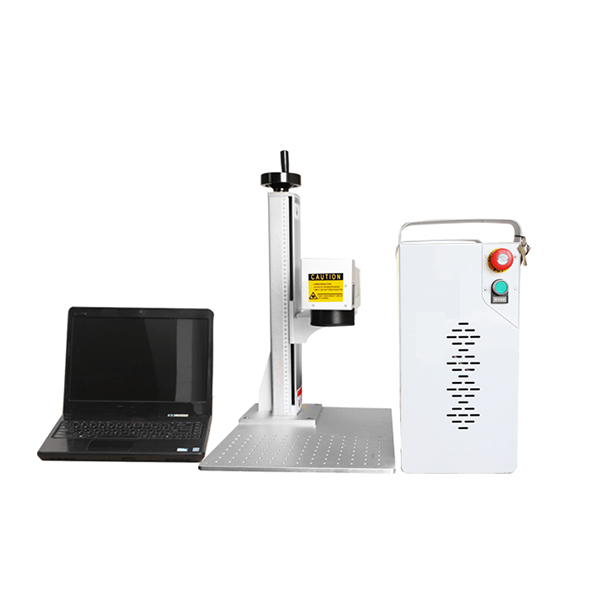

Fiber Laser Marking Machine

Fiber laser marking machine is a kind of laser machine with fiber laser source, it most use for surface marking and deep engraving on metal, it can also marking on plastic material. Their strong power lets them engrave, mark, or etch metals quickly and effectively. However, one drawback is that they can generate a lot of heat, which might not be ideal when working with plastics or when you need precise markings on metals.

What are Fiber Laser Marking Machines?

What is a Fiber Laser?

Fiber lasers operate at a wavelength of 1064nm, While they can mark various materials, they are especially designed for marking metals. Their high output power makes them ideal for deep engraving and other marking tasks that require quick turnaround times.

Fibre laser markers use the same technology found in optical fibers used for long-distance communication. As the laser light travels through the optical fiber, it gets efficiently amplified, enabling the production of a powerful fiber laser.

FIBER LASER MARKING MACHINE

-

2024 Top Rated Fiber Laser Gun Engraving Machine For Sale

Подробнее -

30W Fiber Laser Marking Machine

Подробнее -

3D Fiber Laser Engraver For Metal

Подробнее -

3D Laser Engraving Machine with Large Engraving Area

Подробнее -

50W Split Fiber Laser Engraving Machine

Подробнее -

All-in-One Fiber Laser Marking Machine

Подробнее -

Fiber Laser Deep Metal Engraving Machine for Sale

Подробнее -

Fiber Laser Engraving Cutting Machine For Metal Jewelry

Подробнее -

Glass Laser Drilling Machine | MOPA M8 Glass Laser Cutting Machine

Подробнее -

Handheld Fiber Laser Marking Machine 20W, 30W, 50W

Подробнее -

Mini Cabinet Laser Marking Machine

Подробнее

What is MOPA Laser & Why is it Important?

The MOPA represents a new generation of laser technology, which also use YVO4 lasers with the long lifespan and excellent radiation properties of fiber lasers. It uses a YVO4 laser oscillator as the master oscillator to generate pulses, which are then amplified by a YVO4 amplifier. This design allows for the amplification of the pulses while maintaining their high peak power and exceptional quality.

Additionally, the MOPA use single-emitter pumping laser diodes, which is a key advantage of fibre lasers. This results in lower heat density compared to the multi-emitter laser diodes found in traditional solid-state lasers.

Laser marking machine can marking on metal, polymer gun,etc

This machine can marking on all metal material, and it can cutting gold silver brass etc.

Marking normal keyboard and back light keyboard, bogong provide you templates for keyboard marking.

Metal and Nonmetal pen marking work, choose fixture for pen.

Choose a best 3D laser machine for your glass bottles or cups, etc.

Remove cover on mirror, there have several type of laser marking machine which can work on mirror.

PICK YOUR PERFECT FIBER LASER MARKING MACHINE FOR BEGINNERS & PROS

Fiber Laser Marking Tools: A Comprehensive Buying Guide

Selecting the right fiber laser marking machine is crucial, whether you’re operating a small business, working in a professional setting, or pursuing a hobby. The benefits of these machines are obvious, but how do you know which one suits your needs best? Key factors to consider include laser power, marking area, and compatible software. This guide is here to help you make an informed choice, so let’s dive in!

Why Fiber Laser Marking Machines Are a Great Choice

One of the main advantages of investing in a laser marking machine is the remarkable precision they provide. Whether you’re creating intricate designs, numbers, barcodes, or images, these machines are designed to deliver outstanding accuracy. They use software such as EZCAD or Lightburn, which greatly reduces the likelihood of errors. Moreover, laser marking is faster and more efficient than hand marking, allowing you to produce complex designs in less time. Overall, laser marking machines are versatile tools that offer significant benefits for both personal and professional projects.

**How Laser Marking Works**

Laser marking relies on computer programming. First, you create a design and upload it into the marking software. When you start the CNC program, the machine follows your commands. The laser beam is reflected through XY mirrors and focused on the target material. This process either burns or evaporates the material, creating a contrast that reveals your design. In no time, you’ll have your completed marked project!

Where Fiber Laser Marking Machines Are Used

These machines are commonly use in various industries, such as branding, packaging, and custom products. They are ideal for creating promotional signage, metalworking, and customized electronics. The versatility of laser technology makes it an excellent option for anyone looking to personalize or customize their items.

Pricing for Fiber Laser Marking Machines

If you’re considering purchasing a fiber laser marking machine for personal or professional use, it’s important to know what to expect regarding costs. As of 2024, the average price for a new laser marking machine is approximately $4,200, although this can vary based on factors like laser power and the size of the marking area. Smaller models aimed at hobbyists typically cost around $2,260, while professional-grade machines can reach up to $9,800, especially if they come with custom features.

Pros of Laser Marking:

– Ideal for precise, small-scale machining tasks.

– Can be equipped with a microscope or camera for inspecting the engraving surface.

– Able to mark components within transparent materials like quartz and glass.

– Works efficiently with various metals and other materials.

– Uses less material due to the fine thickness of the laser beam.

– Produces no X-rays during the marking process, enhancing safety.

– Capable of accurately marking tiny components.

– The technique does not wear out tools, making it environmentally friendly.

– The focused laser beam enables detailed markings from different angles.

– User-friendly technology ensures fast and efficient marking in production settings.

Cons of Laser Marking:

– There is a potential risk of eye damage due to the short wavelength of lasers, necessitating the use of protective eyewear.