Portable handheld laser welding machines are advanced tools designed for precise welding across various industries. These machines use a high-energy laser beam, which is transmitted through an optical fiber. The beam is then converted into parallel light using a collimating lens and focused on the weldable metal parts, generating heat to bond them together.

These portable laser welders are easy to maneuver and operate with a handheld laser welding gun, making them suitable for metal joint connections both indoors and outdoors. Their user-friendly design caters to both beginners and professionals.

Their flexibility allows for non-contact welding of challenging components. The manual laser beam welder can effectively separate spectrum by time and energy, enabling the creation of multiple simultaneous welds. Compared to traditional MIG, TIG, and electric welders, this technology provides superior precision in welding.

Преимущество ручного лазерного сварщика:

✔ Предлагает различные варианты мощности лазера (1500 Вт, 2000 Вт, 3000 Вт) для различной глубины проникновения.

✔ Портативный и простой в эксплуатации, что делает его идеальным для сварочных работ как в помещении, так и на открытом воздухе.

✔ Высокая скорость сварки - от 2 до 10 раз быстрее, чем у традиционных сварочных аппаратов MMA, TIG и MIG.

✔ Производит прямые и однородные сварные швы, гладкие и чистые, с глубоким проникновением и минимальным сужением, что исключает необходимость полировки и экономит время и затраты.

✔ Создает прочные металлические соединения без деформации и уменьшает образование рубцов.

✔ Низкое потребление материалов и энергии, способствующее увеличению срока службы.

✔ Удобный и безопасный для пользователя, экологически чистый.

Особенности портативной волоконно-лазерной сварочной машины

⇲ Обеспечивает высокую плотность лазерной энергии при минимальной площади термического воздействия, снижая риск деформации и устраняя необходимость в обширной последующей обработке.

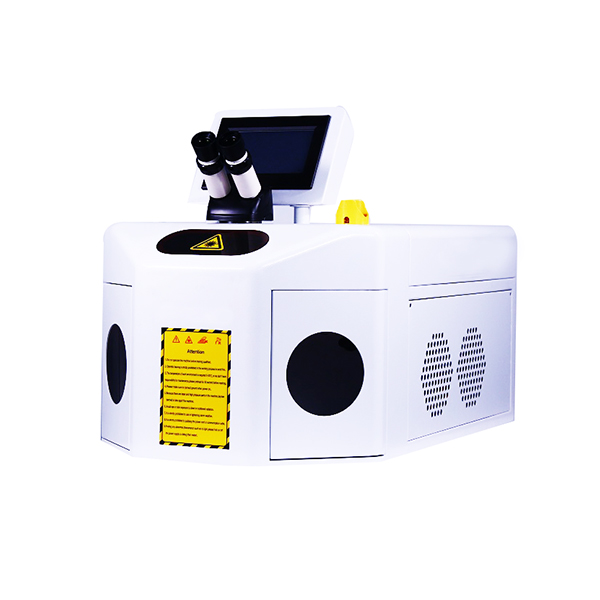

Компактный универсальный шкаф управления, включающий лазерный генератор, блок питания, промышленный охладитель воды и контроллер, - мощный и легкий в перемещении.

⇲ Поддерживает различные методы сварки, включая точечную, шовную, гвоздевую, стыковую, нахлесточную, сплавную, кромочную, штабельную, обжимную и тройниковую.

⇲ Передовые функции обнаружения и защиты обеспечивают стабильную длительную работу, сводя к минимуму возможные потери и риски безопасности.

⇲ Бесконтактный режим работы - это отсутствие напряжения, шума и экологичности, что соответствует стандартам "зеленой" обработки.

⇲ Производит высококачественные сварные швы с гладкой и чистой поверхностью.

⇲ Коммуникационные возможности позволяют отслеживать все данные лазера в режиме реального времени.

⇲ Оснащен специализированным волокном для заварки крошечных неровностей припоя.

⇲ Высококачественный луч волоконного лазера обеспечивает высокую эффективность преобразования, что приводит к быстрой скорости обработки, высокому соотношению сторон и прочным сварным швам.

⇲ Передовая спектральная система снижает потери энергии, обеспечивая равномерное распределение лазерной энергии по всем волокнам.

⇲ Используют оптоволоконную передачу для дистанционной сварки и легко интегрируются с автоматическими верстаками, манипуляторами и сборочными линиями, что позволяет получить более равномерные световые пятна и эстетически привлекательные паяные соединения.

⇲ Множество входных и выходных сигналов облегчают автоматизацию производства и интеграцию сборочных линий.

⇲ Экологически чистые паяные соединения обладают прочностью и жесткостью, сравнимой или превышающей прочность основного металла.

⇲ Удобный сенсорный интерфейс для простой настройки и эксплуатации, интуитивно понятная операционная система, которую легко освоить.

⇲ Разнообразные угловые сопла и спецификации сопел для подачи проволоки позволяют удовлетворить различные требования к сварочным проектам.

Что такое ручной лазерный сварочный пистолет

A handheld laser welding gun is a portable welder that integrates a laser generator, controller, cooling system, and automatic wire feeder. This versatile tool allows for various welding techniques, including stitch, nail, butt, lap, edge, crimp, and T welding, making it suitable for diverse metal joints. Its flexibility and ease of use enable long-distance and outdoor welding, allowing operators to work on weldable parts at any angle or position, which is ideal for handling complex metal joints.

The construction of the handheld laser welding gun includes a gun body, a cooling chamber, and a protective gas chamber. Its compact and straightforward design makes it easy to operate and transport. It can be easily connected to a cooling medium and a protective gas source, effectively cooling the laser gun and creating a protective gas atmosphere around the working area. This setup ensures reliable weld quality.

BOGONG provide you several brand of laser head for optional, you can see the video below

Portable Laser Welder Applications

Portable laser welders are highly versatile tools capable of welding a wide range of metals and alloys, including stainless steel, carbon steel, brass, copper, aluminum, gold, chromium, silver, titanium, nickel, platinum, rhodium, tantalum, niobium, tungsten, molybdenum, and more. They can handle different combinations of materials, such as welding brass to stainless steel, copper to brass, titanium to molybdenum, titanium to gold, and nickel to copper.

Handheld laser welding machines find applications across various industries, from home use to large-scale manufacturing:

Aviation

Used for engine casings, wing spacers, fuselage skins and ribs, wall panels, and bellows.

Electronic Instruments

Welds integrated circuit leads, picture tube electron guns, all-tantalum capacitors, speed control tubes, and instrument hairsprings.

Machinery

Ideal for precision springs, dot matrix printer parts, metal thin-walled bellows, thermocouples, and electro-hydraulic servo valves.

Steel Metallurgy

Efficient in welding silicon steel sheets with thicknesses from 0.2mm to 8mm and widths from 0.5mm to 1.8mm, including high, medium, and low carbon steel, as well as stainless steel, with welding speeds ranging from 100cm/min to 1000cm/min.

Automotive

Used for welding parts such as roofs, body panels, side frames, chassis, transmission components, gear assemblies, and ignition system parts.

High-Speed Rail

Effective for welding the honeycomb structures of train car bodies.

Shipbuilding

Utilized for working on decks, cabin bulkheads, walls, and flat plate sandwich members.

Medical

Involved in the production of pacemakers and lithium-iodine batteries used in these devices.

Food Industry

Welds food cans, replacing traditional soldering and contact high-frequency welding methods. This process is non-toxic, fast, material-efficient, and produces aesthetically pleasing joints with excellent performance.

Other Applications

Includes welding for gas turbines, heat exchangers, dry cell zinc and copper casings, and components for nuclear reactors.

Laser welding Samples

Laser Welder vs. MMA Welder vs. MIG Welder vs. TIG Welder

MMA Welder (Manual Metal Arc Welder):

Also known as MMAW or SMAW (Shielded Metal Arc Welder), MMA welders tend to produce a lot of weld spatter and have low efficiency when it comes to using filler metal. They require regular removal of slag and frequent rod changes, which slows down the welding process and decreases overall production efficiency. Additionally, this type of welding relies heavily on the skill and experience of the welder.

MIG Welder (Metal Inert Gas Welder):

MIG welders have a high consumption of wire and generate significant heat, which makes it easy to warp or burn through thin metal sheets. For medium-thickness plates, welding often requires creating grooves, leading to rough seams that need to be polished afterward.

TIG Welder (Tungsten Inert Gas Welder):

TIG welders produce shallow penetration and create a wide melting area, making them suitable primarily for thin sheet metals, but they can cause large deformations. If the current is too high, the tungsten electrode can melt and evaporate, and manual wire feeding can be difficult and inefficient.

Handheld Laser Welder:

In contrast, handheld laser welders are eco-friendly and produce clean, smooth welds with deep penetration and high speeds, leading to minimal deformation. This significantly reduces the need for follow-up grinding or polishing, resulting in straight, uniform welds without the need for highly skilled operators.

While MMA, TIG, and MIG welding typically require experienced welders and considerable training, handheld laser welders are user-friendly and straightforward. They come preset with commonly used parameters, and users can customize settings and save preferences, making it easy for beginners to get started after just a few hours of practice.

In terms of speed, traditional MMA, TIG, and MIG welders usually operate at a maximum of 1 centimeter per second, whereas handheld laser welders can reach speeds of 2 to 10 centimeters per second, offering efficiency that is 2 to 10 times greater than that of manual arc welders. These portable laser welders can handle various types of metals, including carbon steel, stainless steel, galvanized steel, aluminum alloys, and brass, achieving weld penetration depths of up to 8mm for steel and 6mm for aluminum or brass.

Пакет лазерного сварщика

**Почему стоит выбрать BOGONG LASER**

Компания BOGONG славится качеством лазерного оборудования и услуг по послепродажному обслуживанию. Наши станки универсальны и удобны в использовании, разработаны с учетом всех уровней мастерства. Прежде всего, мы ставим во главу угла удовлетворение потребностей клиентов. Будь вы опытным экспертом или новичком, компания BOGONG LASER готова поддержать вас на каждом шагу. Доверьтесь нам и нашему сервису, где превосходство и инновации объединяются для вашего успеха.