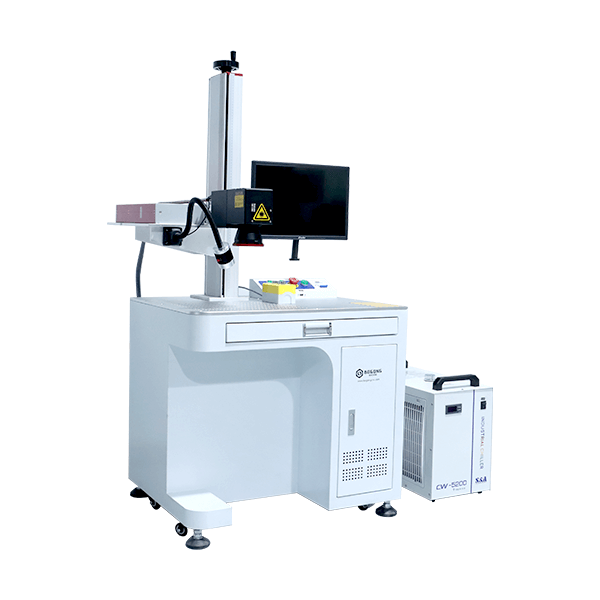

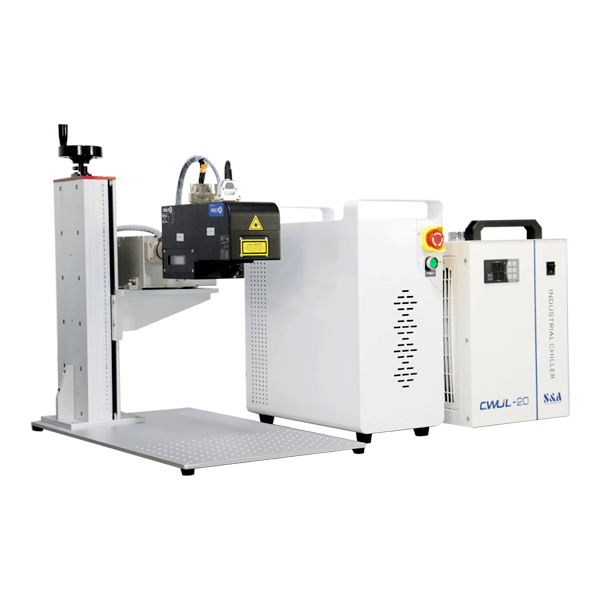

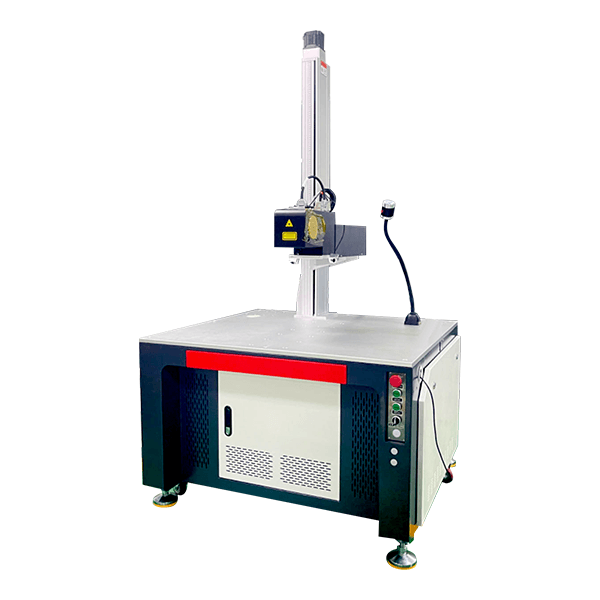

O que é uma máquina de perfuração a laser para vidro?

Um copo máquina de perfuração a laser é uma ferramenta de alta tecnologia que corta o vidro com grande precisão. Ela usa um forte feixe de luz para derreter ou vaporizar o vidro em áreas específicas, o que permite a criação de desenhos e padrões detalhados. Essas máquinas são usadas com frequência em áreas como construção, arte e manufatura, onde a qualidade é importante. Elas têm benefícios como menos desperdício, tempos de produção mais rápidos e a capacidade de trabalhar com peças de vidro grossas e finas de forma fácil e eficaz.

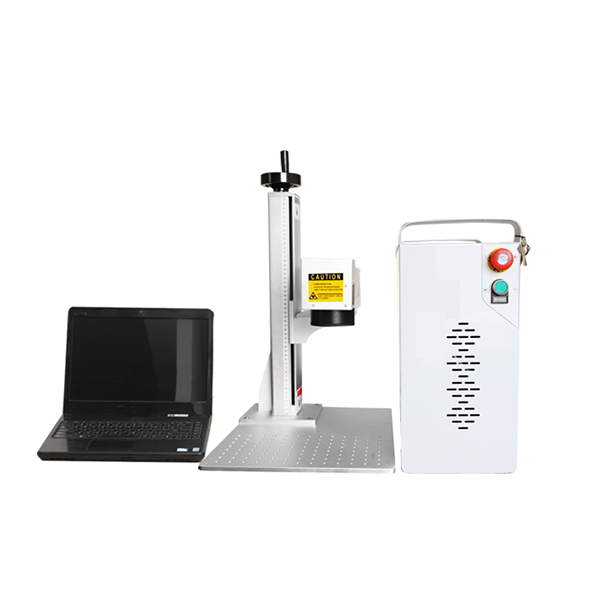

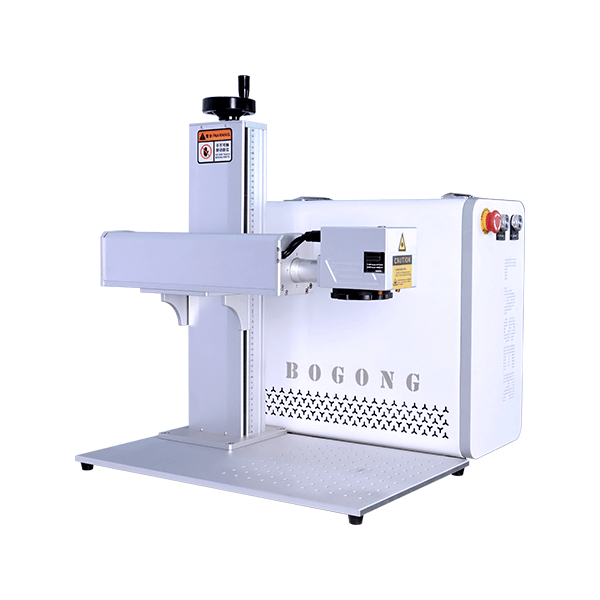

- Fonte de laser M8

- Software de corte 3D

- Ampla seleção de opcionais

- 2 anos de garantia

Como o corte de vidro a laser difere dos métodos tradicionais de corte de vidro? Os dois processos variam significativamente em termos de técnica, equipamento, eficiência e resultados finais.

Corte de vidro tradicional

Quando se trata de corte de vidro tradicional, há três métodos principais usados na produção industrial: retificação CNC, corte com jato de água e corte com rebolo.

-Corte a jato de água: Esse método usa água em alta pressão misturada com areia abrasiva para cortar o vidro. É capaz de criar formas curvas e furos com grande precisão, mas requer muita água e areia, o que pode ser caro e causar um sério impacto ambiental.

- Corte com disco: O corte com rebolo envolve o uso de um rebolo de faca para marcar linhas no vidro e, em seguida, aplicar pressão para quebrá-lo ao longo dessas linhas. Embora esse método seja acessível e fácil de usar, ele geralmente produz lascas e bordas irregulares, dificultando a obtenção de cortes precisos, especialmente em peças menores. A segurança também é uma grande preocupação para os trabalhadores durante esse processo.

- Esmerilhamento CNC: Essa técnica perfura o vidro para dar forma e contorno, mas requer uma furadeira resfriada a água e um sistema de recuperação. As brocas se desgastam rapidamente, o que pode aumentar os custos e desacelerar a produção.

Corte de vidro a laser Perfuração

Por outro lado, o corte de vidro a laser está se tornando cada vez mais popular devido à sua capacidade de atender aos padrões precisos e exigentes requeridos nas aplicações atuais. O corte a laser pode ser dividido em duas categorias: corte de vidro a laser e perfuração de vidro a laser. O corte a laser geralmente usa lasers de picossegundos que emitem pulsos ultracurtos com alta potência, e o preço desse tipo de máquina é muito caro. Enquanto as máquinas a laser comuns podem ser usadas para perfuração, elas usam a fonte de laser M8, e o preço de custo é comparável ao do laser de picossegundos. Ao escolher um método de corte a laser, é importante considerar várias aplicações e equilibrar custo, eficiência e qualidade.

O vidro temperado pode ser cortado com um laser? Sim, mas é necessário um tipo especial de laser chamado laser de picossegundos, pois os lasers comuns não conseguem cortá-lo adequadamente. As máquinas a laser comuns, como os lasers MOPA, são boas para cortar vidro de cal sodada, que é o tipo mais comumente usado. De fato, cerca de 75% de todo o vidro produzido é de cal sodada.

Outros tipos de vidro que podem ser cortados com laser incluem borosilicato, vidro de chumbo, aluminossilicato e fibra de vidro. O vidro colorido, que é frequentemente usado para decoração, também pode ser cortado com um laser, mas pode se quebrar facilmente. O corte a laser também é adequado para vidro temperado, vidro reforçado por calor e vidro refletivo.

Configurações favoráveis para corte de vidro a laser

Potência do laser: a potência do laser utilizado deve estar entre 30W e 800W, dependendo da espessura e do tipo de vidro. Essa faixa é importante porque o vidro absorve a luz de forma eficaz nos comprimentos de onda adequados.

Velocidade de corte: A velocidade de corte do vidro com um laser é influenciada pela espessura do vidro. Em geral, é possível cortar mais rápido aumentando a potência do laser. Por exemplo, um laser de 80 W pode cortar vidro de 0,10 polegada de espessura a uma velocidade de cerca de 15 polegadas por minuto.

Área de trabalho: O tamanho da área de trabalho do gravador a laser é outro fator importante. Você precisará escolher um cortador a laser que possa acomodar as dimensões das chapas de vidro que planeja usar.

Lentes: Ao trabalhar com vidro, é melhor usar lentes que atendam aos padrões ISO-10110. Você precisará de uma lente de distância focal curta com um ponto focal profundo para garantir que o feixe de laser permaneça focado em um ponto pequeno, o que é fundamental para cortar vidro espesso. Uma lente recomendada para o corte eficaz de vidro teria uma distância focal de 2 polegadas, uma profundidade de campo de 0,03 polegadas e um tamanho de ponto de 0,001 polegadas.

Sistema de ventilação: Embora o corte a laser de vidro normalmente não produza poeira ou gases visíveis, ainda é essencial ter um bom sistema de ventilação. Os vapores liberados podem variar em termos de toxicidade, dependendo dos materiais usados, especialmente no caso de vitrais, que podem produzir vapores escuros visíveis quando cortados. Um sistema de ventilação robusto pode ajudar a remover rapidamente esses vapores e minimizar o risco de corrosão ou manchas nas peças da máquina.

As máquinas de corte a laser para vidro oferecem vários benefícios, incluindo a produção de bordas com acabamento natural e excepcionalmente lisas. Ao contrário dos métodos tradicionais de corte de vidro, o corte a laser resulta em alta resistência à ruptura e requer manutenção mínima.

Os processos automatizados e orientados por computador usados no corte a laser levam a resultados rápidos e econômicos. Os lasers podem cortar vidro de espessuras variadas em praticamente qualquer formato, tornando esse método a escolha preferida de muitas empresas de diferentes setores devido à sua velocidade, limpeza, precisão e opções de personalização.

Os cortadores a laser industriais oferecem grande flexibilidade na criação de várias formas e, ao mesmo tempo, fornecem detalhes intrincados com precisão notável. Essa técnica de corte a laser também minimiza o desperdício de material, o que ajuda a reduzir os custos em geral.

Você pode encontrar mais comentários de clientes no canal do youtube da BOGONG.

Condições de pagamento

1. Depósito e saldo: Um depósito de 30% T/T é exigido antecipadamente, com o saldo devido antes do envio.

2. Garantia de comércio do Alibaba: Os pagamentos podem ser processados por meio do Alibaba Trade Assurance.

Perguntas frequentes sobre o vidro Máquina de corte a laser

Qual é a embalagem da máquina de perfuração a laser para vidro?

Nossas máquinas são embaladas em uma configuração de três camadas. A camada externa consiste em um engradado de madeira, a camada intermediária apresenta estofamento de espuma para proteger contra trepidações e a camada interna inclui um saco plástico grosso para impermeabilização.

O pacote será danificado durante o transporte?

Projetamos meticulosamente nossas embalagens para lidar com todos os fatores de possíveis danos, e nossos agentes de transporte têm experiência em transporte seguro. Já exportamos com sucesso para 180 países, portanto, você pode ter certeza de que sua encomenda chegará em excelentes condições.

A maioria dos clientes prefere escolher o transporte por UPS/DHL express, que pode chegar ao destino em cerca de 5 a 7 dias. Laser BOGONG para obter mais detalhes sobre a máquina de marcação a laser uv.