-

Shunhua Road, cidade de Jinan, Shandong

Máquina de limpeza a laser para remoção de ferrugem

Máquina de limpeza a laser para remoção de ferrugem

Laser cleaning machines are divided into pulsed laser cleaners and continuous laser cleaners based on the type of laser used. Continuous laser also named CW Laser cleaner, I hope this article helps you better understand which type of machine you should choose.

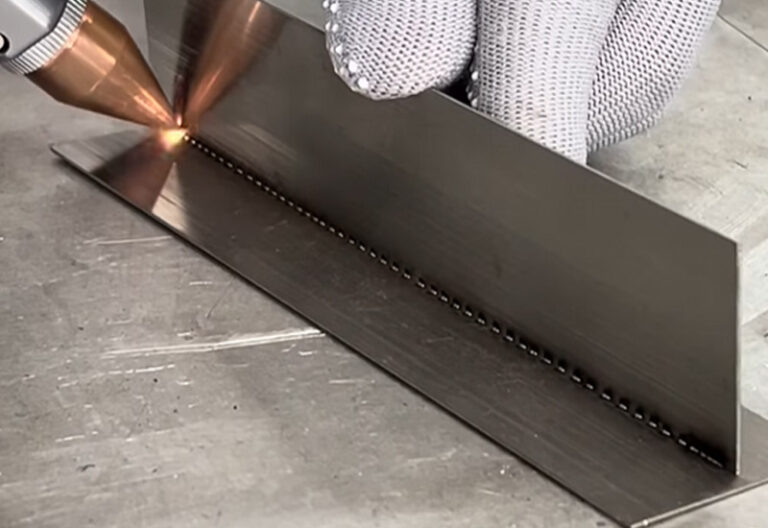

CW Laser Cleaning Machine for Rust Removal

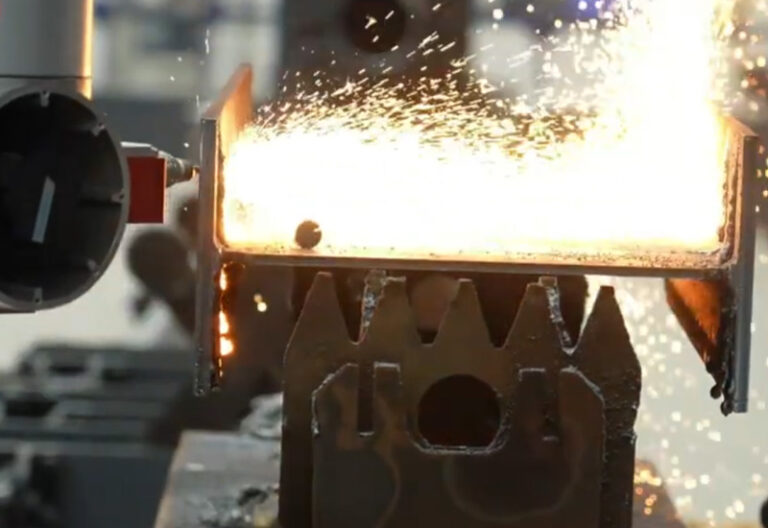

Pulse Laser Cleaning Machine for Rust Removal

How Does Laser Rust Removal Work?

Antes e depois da limpeza a laser das imagens de remoção de ferrugem

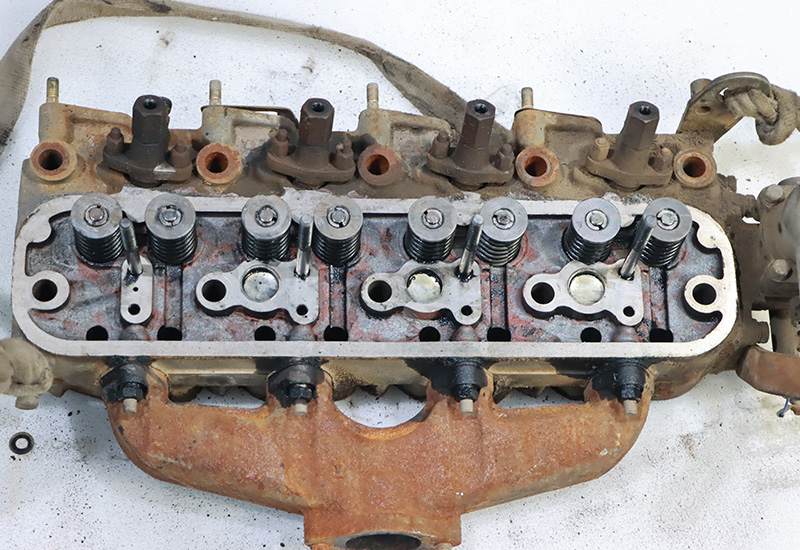

Superfície de aço enferrujada antes e depois da limpeza a laser

Peças metálicas corroídas limpas por laser antes e depois

Remoção de ferrugem em componentes de maquinário pesado antes e depois

Máquina de limpeza a laser para remoção de ferrugem Antes da limpeza (1)

Advantages and Disadvantages of Laser Rust Removal

1. Environmentally Friendly

This method is eco-friendly because it does not use chemicals or produce waste. The rust material turns into gas and vapors, leaving no harmful residues behind. Unlike traditional methods such as sandblasting, grinding, or chemical treatments, laser cleaning reduces environmental impact and waste.

2.Damage-Free Process

Laser rust removal gently eliminates rust without damaging the surface of the part. The focused laser light evaporates the rust cleanly, maintaining the part’s original structure and finish.

3. Minimal Manual Work

Laser rust removal is quick and simple, requiring only basic setup and part placement. It takes seconds or minutes for small areas and doesn’t need extensive manual labor. In contrast, traditional methods like wire brushing, sanding, or outsourcing can be time-consuming and costly.

Disadvantages of Laser Rust Cleaning

Laser rust cleaning can be expensive to set up due to the cost of laser equipment. It also requires trained operators to handle the machine safely and effectively. For very large areas, the process may take longer and be less efficient compared to traditional methods. Additionally, if the surface is very reflective or uneven, the laser may have difficulty focusing properly. These limitations mean that laser cleaning might not always be the best choice for every rust removal job.

Recomendação de produtos para máquinas de limpeza a laser

Máquina de limpeza a laser de pulso de 1000 W

Máquina de limpeza a laser de pulso de 500 W

Melhor máquina de limpeza a laser de pulso de 200 W

Melhor máquina de limpeza a laser de pulso de 300 W

Máquina de limpeza a laser CW

Máquina de limpeza a laser de pulso com laser Raycus Max JPT

Máquina de limpeza a laser tipo maleta com carrinho

Key Industries That Benefit from Laser Rust Removal

Automotivo

Aerospace

Defense and Military

Medical Equipment

Semiconductors

Aplicação da máquina de limpeza a laser

Perguntas frequentes (FAQ)

Entre em contato conosco para ajudá-lo a escolher a máquina de limpeza a laser mais adequada para você:

Entre em contato conosco agora para discutir suas necessidades de remoção de ferrugem e receber uma solução personalizada:

Blog da BOGONG LASER® - Aplicação da máquina de limpeza a laser e informações sobre o setor

CO2 Laser Cutting Machine for Foam Tool Inserts

CO2 laser cutting for foam tool inserts: improve tool control, reduce waste, and upgrade your workshop look with BOGONG Laser CNC solutions for global industrial users.

Handheld Laser Welder for Display Sign Frames

Handheld Laser Welding Machine for display sign frames: cut grinding, reduce distortion and boost finish quality with BOGONG LASER® welding solutions for signage.

Laser Metal Cutting Machine for Construction Formwork

Laser Metal Cutting Machine for construction formwork. Cut cleaner panels, reduce scrap, speed delivery. BOGONG LASER helps factories upgrade cutting for real site demands.

Fiber Laser Cutting Machine for Kitchen Exhaust Hoods

Fiber Laser Cutting Machine for kitchen exhaust hoods: improve cut quality, airflow parts and lead time with BOGONG LASER, a global laser cutting machine manufacturer.

Fiber Laser Marking Machine for Bearing Batch Codes

Fiber laser marking for bearing batch codes. Learn how BOGONG Laser machines boost traceability, fight counterfeits and cut rework for global bearing makers.

Laser Engraving Machine for Tumbler Customization

Looking for stable tumbler branding? Discover how BOGONG Laser Engraving Machine solutions help factories customize cups in-house and grow B2B orders.