-

Shunhua Road, cidade de Jinan, Shandong

How Industrial Buyers Select the Right Fiber Laser Cutter

Choose the right Fiber Laser Cutting Machine with real-shop tips on power, nesting, envelope, gas, and ROI—built for B2B buyers. Talk to BOGONG Laser today.

You don’t pick a Fiber Laser Cutting Machine by staring at a spec sheet. You pick it by staring at your parts list, your takt, and your floor reality. In plain words: match what you cut, how often you switch, how you move material, and how you keep uptime high

First, define the job before the machine

| What you cut | How often | Typical thickness bands | Sheet or tube | Surface finish ask | Notes for process window |

|---|---|---|---|---|---|

| Core SKUs you run daily | High / Medium / Low | Thin / Mid / Thick | Sheet / Tube / Combo | Bare / film / aesthetic edge | Piercing behavior, micro-joints, kerf width, HAZ tolerance |

| Seasonal or custom | Burst / sporadic | Thin / Mid / Thick | Sheet / Tube / Combo | Painted / coated | Edge oxidation allowed or no? post-process needed? |

| Prototype / R&D | Random | Mixed | Sheet / Tube / Combo | Doesn’t matter / matters a lot | Short programs, small nests, frequent changeover |

Power vs. thickness is a triangle, not a line

More power is not always “better.” It’s a trade: pierce time, cut speed, and edge look live in a triangle with cost and energy. If your dominant work sits in a single band, tune power for that band. If you run a spread, don’t just chase headline speed—optimize for stable quality and predictable cut times across the whole set. Empty-bed speed tells nice stories; shift-end throughput tells truth.

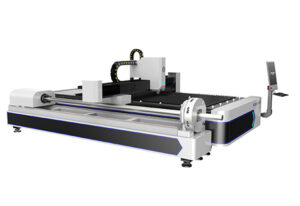

Work envelope + material flow beats raw speed

Work area (and how you load it) quietly decides hourly output. Bigger sheets can boost nesting yield and reduce swaps, if your material logistics can keep up. If your crew spends half their time wrestling pallets, you lost the speed you paid for.

When sheet-and-tube share the schedule, a combo platform simplifies planning and cuts WIP handoffs. That’s where a plate-and-tube combo shines—one program, one nest logic, fewer cranes.

For integrated sheet + tube scenarios, see Máquina de corte a laser de fibra combinada para placas e tubos.

For automatic tube feeding to keep operators out of the danger zone, check Máquina de corte de tubos a laser com carregamento automático.

For tight workshops or small parts work where “big bed” just slows you down, look at Máquina de corte a laser de fibra 5050 ou Máquina de corte a laser de fibra 3020.

When bevels and prep edges matter, Máquina de corte a laser de fibra chanfrada reduces secondary ops.

Software and nesting: the “invisible” throughput

Cut speed is loud. Nesting yield and first-article time are quiet. But that quiet decides cost per part. Look for:

Nesting quality: tight packing, bridge/micro-joint control, corner strategies, heat avoidance.

Tech tables: sane defaults for your metals; minimal knob-twisting.

CAM-to-shop sync: quick post, zero drama at the control.

Short-run agility: template rules that handle frequent changeover without “wizard fatigue.”

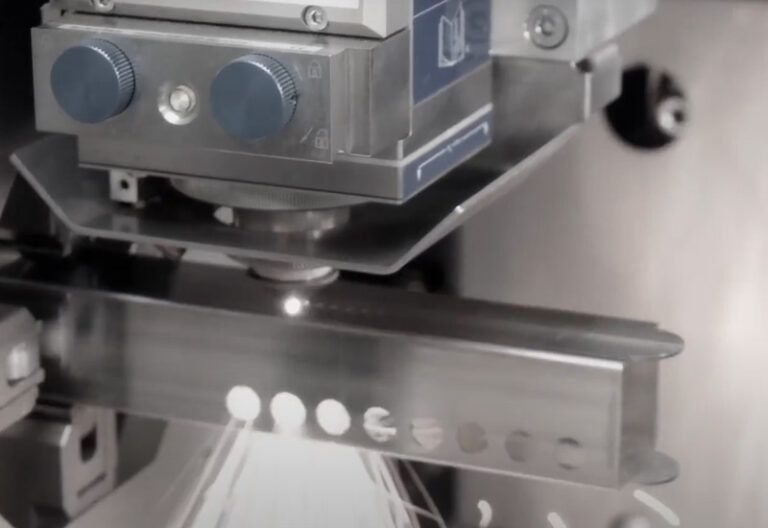

Machine structure and stability: speed you can actually use

At high accelerations, weak frames whistle and parts chatter. You want a bed and gantry that stay put, drives that don’t hunt, and servo tuning that doesn’t overshoot corners. Check for:

Stiff frame + beam: less taper, cleaner corners at speed.

Guides + rack quality: repeatability after long runs.

Backlash control: circles are round, not eggs.

Thermal behavior: long shifts, consistent size.

Assist gas choices change edge, cost, and takt

Oxygen is fast on certain steels but can leave oxide; nitrogen is cleaner for cosmetic edges; dry air can be a cost-saver in the right window.

| Goal | Likely gas | Edge look | Notes |

|---|---|---|---|

| Cosmetic edge, minimal discolor | Nitrogen | Bright / clean | Watch purity, nozzle wear, and gas supply logistics |

| Faster pierce on certain steels | Oxygen | Oxidized edge allowed | Good for non-cosmetic parts; downstream steps may remove color |

| Balanced cost for utility parts | Ar | Acceptable edge | Needs proper dryers/filters; fine for utilitarian finishes |

Automation: buy back your minutes

Automatic loading/unloading, nozzle cleaning, and scrap handling remove dead time that planners often ignore. If your order book is mix-model with short nests, the right automation closes the gap between “rated speed” and “real parts out.” It also lowers injury risk—no one argues with fewer manual lifts.

This is where Máquina de corte de tubos a laser com carregamento automático can change the daily rhythm, especially when tube jobs stack up. Pair that with a combo bed if your schedule blends sheet and pipe.

A quick buyer’s checklist

| Question | Why it matters | What “good” looks like |

|---|---|---|

| Does the machine’s sweet spot match our top SKUs? | Most hours land here | Stable edges at planned feed, minimal babysitting |

| How fast from DXF to first part? | Real takt includes programming | Clean post, smart defaults, no ritual hacks |

| What’s our assist-gas plan? | Edge + cost + logistics | Source + purity defined; dryer/filter maintained |

| Can operators swap nozzles/optics fast? | Downtime kills ROI | Clear procedures, easy access, spare kits on hand |

| What’s the service reach and spares plan? | Uptime is king | Remote support, parts nearby, training that sticks |

| Do we need bevel or tube often? | Removes secondary ops | Dedicated bevel head or combo machine available |

| How will we load/unload safely? | Safety + throughput | Auto-loaders or simple jigs; no hero lifts |

| Did we validate on our parts? | Demos lie, parts don’t | Corners, holes, heat maps, finish checks passed |

Why BOGONG Laser fits this

BOGONG Laser isn’t chasing one hero spec. The catalog maps to real-world scheduling: compact beds for tight factories, combo systems for mixed tube/sheet days, bevel heads for weld-ready prep, high-power lines for heavy duty. As a Factory Manufacturer with certification pedigree, the team supports OEM/ODM, training, and multilingual service—so operators learn once and run steady. More importantly, the product family lets you grow without re-writing your playbook. That’s how you keep throughput honest and costs sane.

Pulling it together

Selection isn’t about a single headline. It’s a chain: parts mix → power window → nesting + software → envelope + automation → assist gas → validation → service. Break the chain at any link and the day gets long. Keep it intact and the shop hums.

BOGONG Laser has those paths covered with Máquina de corte a laser de fibra families and focused variants—pick the one that matches your reality.

If you want to know more about us, please fill the BOGONG Laser contact form, we will reply fast.