-

Shunhua Road, cidade de Jinan, Shandong

High-Precision Laser Engraving Machines for Electronics

High-precision Laser Engraving Machine solutions for electronics—clean DPM, low HAZ, stable UPH. Work with BOGONG Laser, a global manufacturer with OEM/ODM.

In today’s electronics world, every micron counts. You need crisp serial numbers, clear barcodes, and tiny logos that survive assembly, coating, and end‑use. That’s where high‑precision máquinas de gravação a laser shine. They deliver repeatable, non‑contact marking with accuracy down to single‑digit microns. Plus, they cut cycle time and scrap rates, so you keep lines running and customers smiling.

What “high precision” really means on your line

In day-to-day production, high precision shows up like this:

Repeatability: you hit the same spot again and again—micron-level.

Edge quality: sharp sidewalls, low recast, minimal heat-affected zone (HAZ).

Alignment: the mark sits exactly where the MES says—after panel warp, after reflow, after the weekend.

- Stability over time: long runs without drift—chiller hiccups, room temp swings, or galvo creep don’t wreck parts.

Stability over time: long runs without drift—chiller hiccups, room temp swings, or galvo creep don’t wreck parts.

Why High-Precision Laser Engraving Matters in Electronics

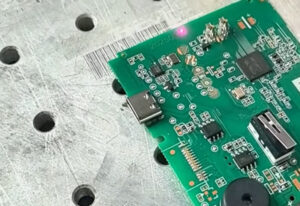

Electronics parts live on tight tolerances. Even a tiny misalignment or excess heat can wreck functionality. Laser marking dodges those pitfalls. It’s non‑contact, so no mechanical stress on delicate PCBs or fine connectors. You skip burrs, tool wear, and cracking. Instead, you get sharp edges and legible text that lasts under conformal coatings. Traceability jumps ahead: 2D data‑matrix codes stay scannable after harsh environments.

Core Technologies in High-Precision Laser Engraving Machines

To hit those specs, modern Laser Engraving Machines for Electronics blend several innovations:

Fiber, MOPA, CO₂, and UV Laser Engines

- Lasers de fibra deliver stable, high‑peak power for marking metal housings.

- MOPA fiber lets you tweak pulse width, shrinking the heat‑affected zone.

- CO₂ lasers excel on PCB substrates and plastics.

- Lasers UV use ultra‑short wavelengths to minimize taper and “halo” marks.

Galvo Scanners, Pulse Control, and Process Window

Galvo mirrors steer the beam at blistering speed, so you land micro-text and logos without slowing the line. Pulse control sets dwell time—from very short to relatively long bursts—letting you tune depth and contrast while avoiding board burn. Closed-loop monitoring keeps beam jitter tightly contained, locking in a stable process window and clean, repeatable patterns across large production runs.

Scenes Of Laser Engraving Electronic Products

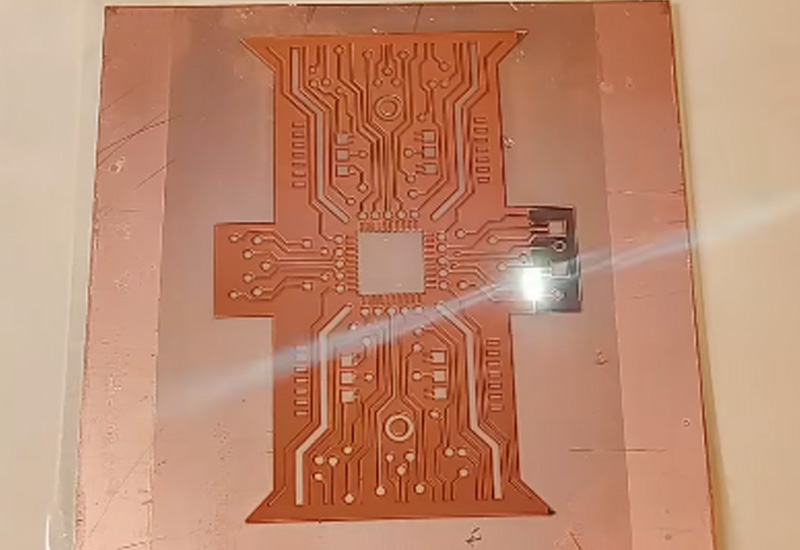

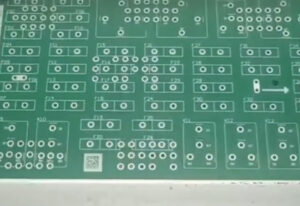

PCB Traceability and 2D Data Matrix Marking

A contract manufacturer needed clear QR and DataMatrix codes on multilayer PCBs. They switched to our Máquina de marcação a laser de fibra de 30W and dialed in an ultra-fine line width. Even after solder-mask and full soldering, the codes kept their contrast and scanned on the first pass.

Connector Housing Branding and Micro‑Text

An automotive connector supplier had to etch part numbers and UL logos on tiny plastic housings. They chose our Máquina de marcação a laser UV 3D for its very small spot and stable focus across height changes. The marks stayed tack-sharp through vibration testing and handling.

Complex Surface Engraving on Metal Casings

A small-batch IoT module maker needed serials on curved aluminum shells. Our Máquina de marcação a laser de fibra multifuncional with a large working area handled the curves cleanly. They rotated the shells under the beam and got uniform depth and legible IDs across the arcs.

How To Select a Laser Engraving Machines Manufacturer and Factory

Choosing a partner isn’t just about specs. You need solid support and certifications.

Certifications: CE, ISO9001, SGS, FDA

Check for global certificates. CE covers EU compliance. ISO9001 proves quality management. SGS and FDA address safety and material standards. On-site audits should show traceable weld logs and material batches.

OEM/ODM Support and After‑Sales Service

Can they tweak firmware or beam optics? BOGONG Laser offers OEM/ODM. You get custom beam parameters and fixtures. They host virtual tradeshows for operator training.

Integrating BOGONG Laser Solutions into Your Production Line

Lean lines need lean gear. Here’s how BOGONG Laser fits in.

Custom Software and Offline Macro Creation

BOGONG’s drag‑and‑drop interface lets you build job templates offline. Network‑push them to all stations. That slashes programming time from hours to minutes.

Maintenance, Duty Cycle, and Uptime

Sealed optics and auto-purge keep lenses clear, so debris doesn’t stick around. You get very high uptime, with duty-cycle ratings built for true around-the-clock runs. Wear items—like galvo motors—swap quickly during a planned stop, and you’re back on line after a short service window.