-

Strada Shunhua, città di Jinan, Shandong

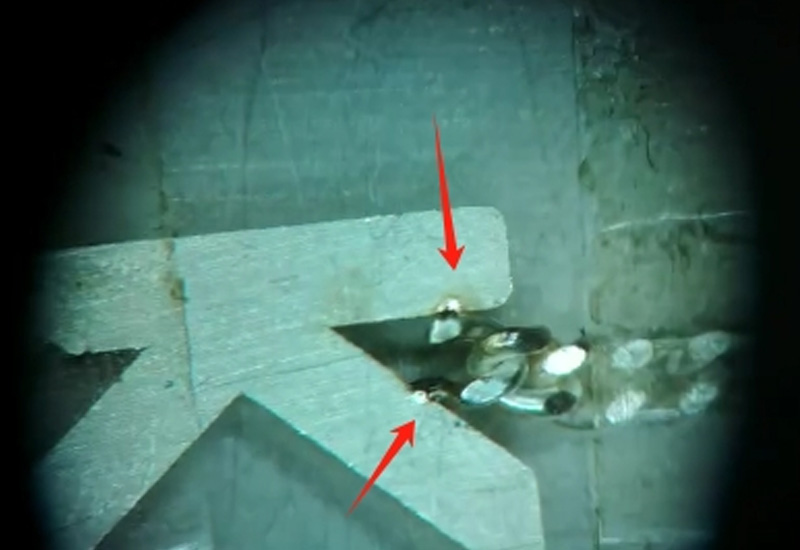

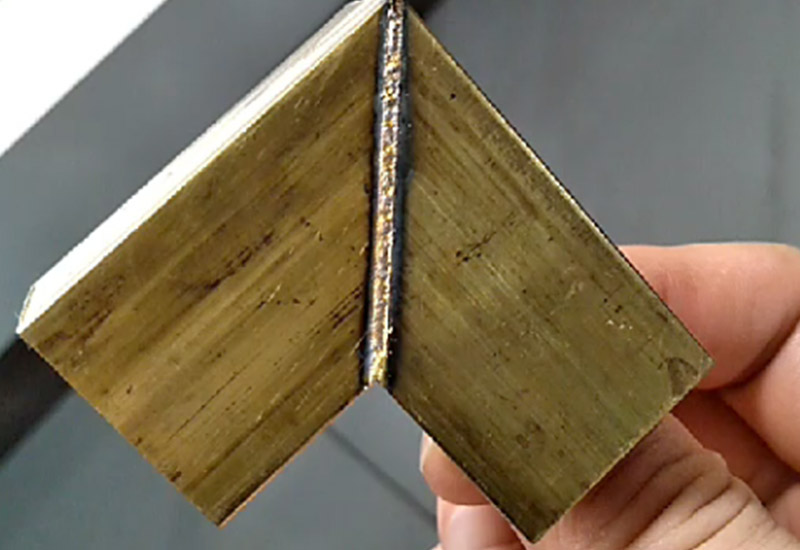

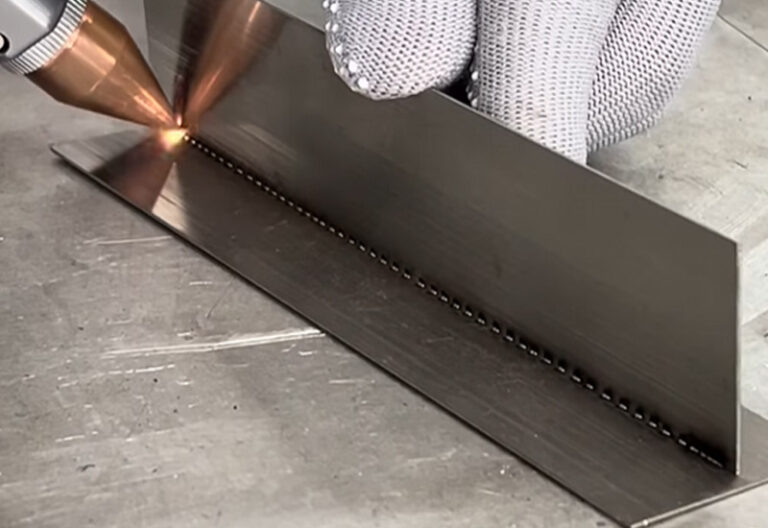

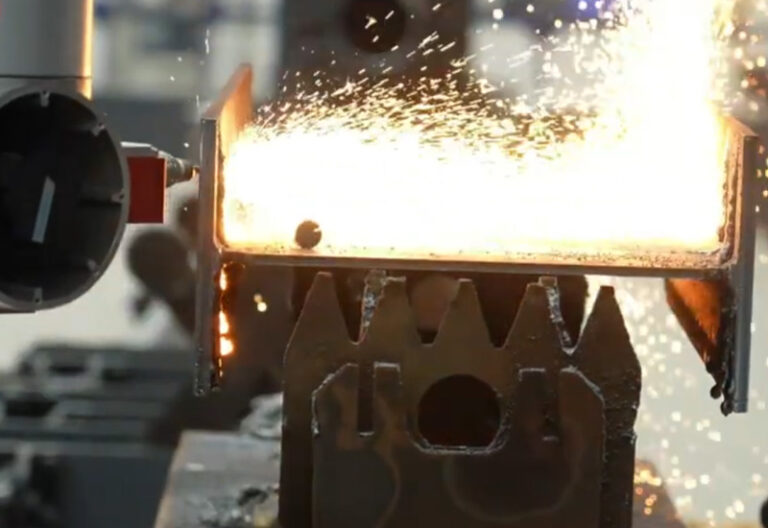

Applicazione della saldatrice laser

Applicazione della saldatrice laser

Applicazione della saldatrice laser

Raccomandazione sui prodotti per la pulizia laser

Saldatore laser portatile:

Portatile e versatile, è ideale per la saldatura in loco, le riparazioni e la manutenzione di una varietà di metalli e componenti. Offre flessibilità e precisione per diverse attività di saldatura.

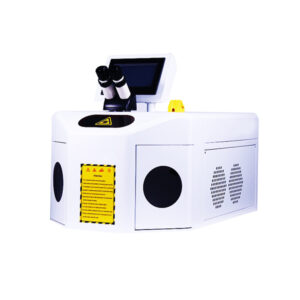

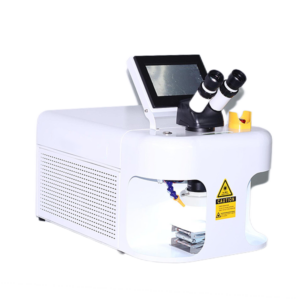

Saldatore laser per gioielli:

Progettato specificamente per saldature fini e delicate su metalli preziosi come oro, argento e platino. Offre un'elevata precisione e un impatto termico minimo, perfetto per la fabbricazione e la riparazione di gioielli.

Entrambi i modelli sono dotati di sistemi di controllo avanzati, prestazioni affidabili e facilità d'uso per soddisfare le vostre specifiche esigenze di saldatura.

200W Popolare Mini macchina di saldatura laser con CCD

200W Pro Mini saldatrice laser con CCD

Migliore saldatrice laser portatile

Saldatrice laser per gioielli 150W

Floor type Laser Welding Machine

Macchina di saldatura laser portatile con raffreddamento ad aria in vendita

Saldatore laser portatile 3 in 1

Laser Protective Fence

2024 Popolare portatile portatile macchina di saldatura laser in vendita

Domande frequenti sulle saldatrici laser

Contattateci per aiutarvi a scegliere la saldatrice laser che fa per voi:

Blog di BOGONG LASER® - Applicazione della saldatrice laser e informazioni sull'industria

CO2 Laser Cutting Machine for Foam Tool Inserts

CO2 laser cutting for foam tool inserts: improve tool control, reduce waste, and upgrade your workshop look with BOGONG Laser CNC solutions for global industrial users.

Handheld Laser Welder for Display Sign Frames

Handheld Laser Welding Machine for display sign frames: cut grinding, reduce distortion and boost finish quality with BOGONG LASER® welding solutions for signage.

Laser Metal Cutting Machine for Construction Formwork

Laser Metal Cutting Machine for construction formwork. Cut cleaner panels, reduce scrap, speed delivery. BOGONG LASER helps factories upgrade cutting for real site demands.

Fiber Laser Cutting Machine for Kitchen Exhaust Hoods

Fiber Laser Cutting Machine for kitchen exhaust hoods: improve cut quality, airflow parts and lead time with BOGONG LASER, a global laser cutting machine manufacturer.

Fiber Laser Marking Machine for Bearing Batch Codes

Fiber laser marking for bearing batch codes. Learn how BOGONG Laser machines boost traceability, fight counterfeits and cut rework for global bearing makers.

Laser Engraving Machine for Tumbler Customization

Looking for stable tumbler branding? Discover how BOGONG Laser Engraving Machine solutions help factories customize cups in-house and grow B2B orders.