-

Strada Shunhua, città di Jinan, Shandong

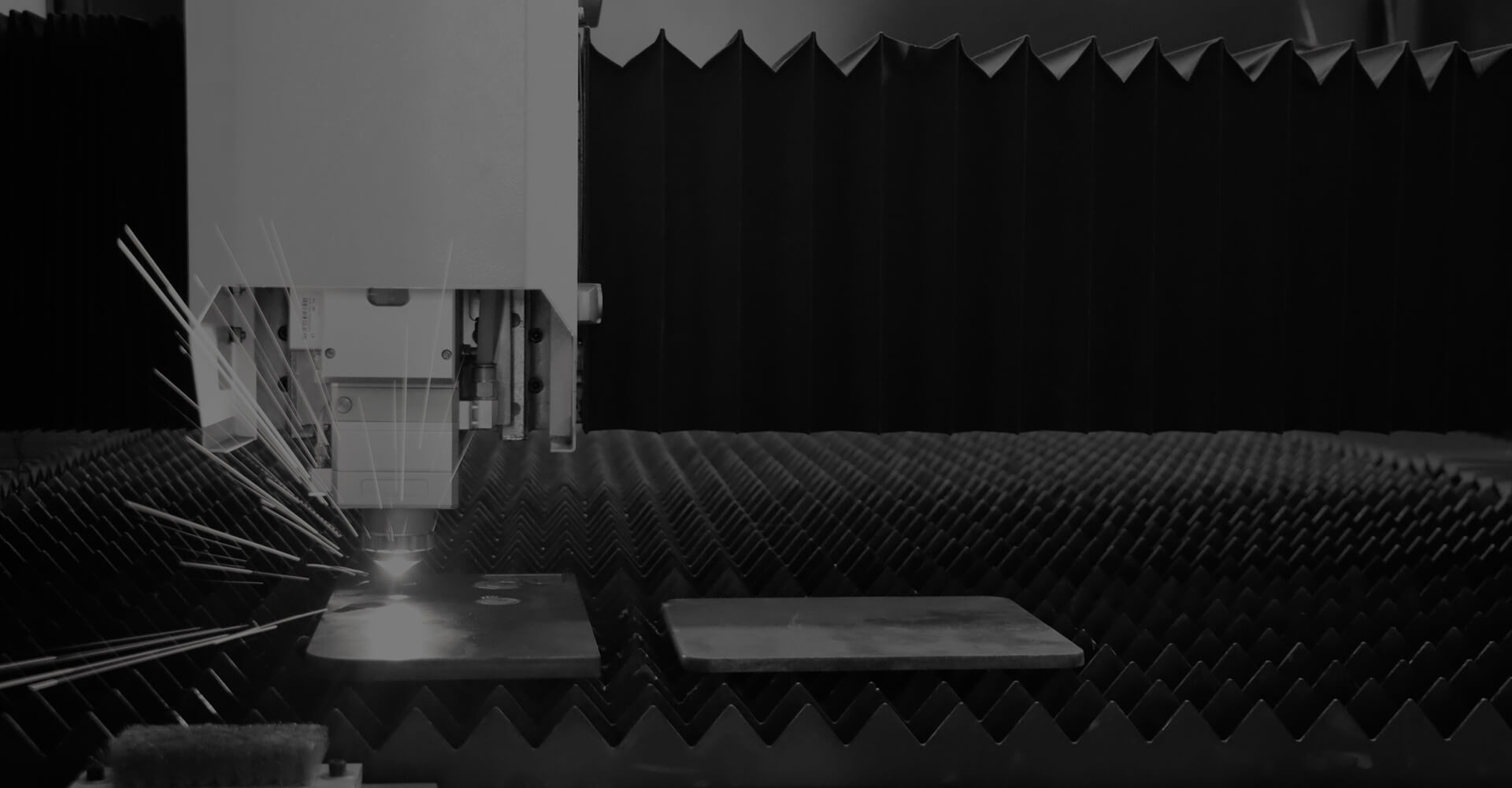

Macchina per l'incisione laser

La macchina per l'incisione laser utilizza un raggio laser focalizzato per incidere disegni, numeri e testi intricati su vari materiali. personalizzazione ad alta velocità di metallo, legno, plastica, ecc.

Visualizzazione di 14 risultati

2024 Top Rated pistola laser fibra incisione macchina in vendita

Macchina di marcatura laser a fibra 30W

Incisore laser a fibra 3D per metallo

Macchina per l'incisione laser 3D con grande area di incisione

Macchina per la marcatura laser UV 3D

Macchina di marcatura laser in fibra all-in-one

Macchina di marcatura laser CO2

Macchina per l'incisione profonda del metallo del laser a fibra in vendita

Tagliatrice dell'incisione laser della fibra per i gioielli del metallo

Macchina di perforazione laser di vetro | Macchina di taglio laser di vetro MOPA M8

Mini macchina per la marcatura laser del gabinetto

Mini macchina per l'incisione laser in fibra Split

Incisore laser portatile

Macchina di marcatura laser UV