-

Shunhua Road, město Jinan, Shandong

Pulzní vs. kontinuální laserové čisticí zařízení Jaký je mezi nimi rozdíl?

Máte už dost škodlivých strategií čištění? Zjistěte, jaké jsou rozdíly mezi pulzními a CW laserovými čističi, a najděte si ten nejlepší stroj pro svůj úkol.

Pokud se nyní rozhodujete mezi pulzním a kontinuálním (CW) laserem, mohu vám říci, že jediný skutečný rozdíl je ve způsobu vystřelování paprsku: pulzní lasery vysílají velmi silné, přesné dávky - představte si odstřelovací pušku - zatímco CW lasery vysílají stálý proud - spíše jako kulomet. Tato volba určuje výkon čištění, dopad na materiál, rychlost a nakonec to, co je pro vaši dílnu, díly a rozpočet nejlepší. Podívejte se na toto krátké video, kde si můžete prohlédnout ukázku.

Pulzní vs. kontinuální laserové čisticí zařízení: Jaký je mezi nimi rozdíl?

Drobné detaily: Jak se pulzní lasery postarají o čistý "studený" vzduch?

Pulzní laser funguje na základě procesu zvaného "fotoablace".

Co to ve skutečnosti znamená. Laser vystřelí dávku energie, která je tak rychlá (mluvíme o nanosekundách) a tak silná, že okamžitě odpaří rez, barvu nebo olej na povrchu. Znečištění absorbuje energii laseru a prostě... exploduje z povrchu. Děje se to tak rychle, že se na kov pod ním nepřenáší téměř žádné teplo.

Proto se tomu říká "čištění za studena". Ve skutečnosti není studené, ale nezahřívá vaši část. To je velmi důležité, pokud pracujete s materiály, které nesnesou teplo. Pro většinu přesných prací je vhodný stroj, jako je např. 500W pulzní laserový čisticí stroj je dokonalým nástrojem, který vám poskytne výkon bez rizika poškození teplem..

Klíčovou výhodou je ovládání. Vrstvu barvy můžete odstranit, aniž byste se dotkli základního nátěru pod ní. Můžete vyčistit jemnou formu s vysokým leskem, aniž byste zničili povrch. Přesnost je šílená.

Energetický dům: Jak CW lasery přinášejí teplo

Laser se spojitou vlnou (CW) je úplně jiný druh laseru. Nepulsuje. Pouze vysílá konstantní proud laserové energie na povrch. Namísto malé exploze funguje CW laser tak, že kontaminant roztaví a vyvaří. Je to prostě a jednoduše tepelný proces, který je rychlý.

Pokud máte velký I-nosník pokrytý silnou vrstvou rzi, CW laser ho protrhne mnohem rychleji než pulzní laser. Jde o vysoký výkon a vysokou rychlost. Pro tyto velké a náročné práce, při kterých nevadí ani trocha tepla na povrchu, se hodí.

CW vláknový laserový čisticí stroj je váš pracovní kůň. Prostě to udělá svou práci. Kompromisem je nulová jemnost. Je to tupý nástroj, ne skalpel.

Hlavní událost: Pulsní vs. CW laserové čištění Head-to-Head

Postavme je vedle sebe. Toto jsou hrubé údaje o rozdílech mezi výkonem čisticího stroje s pulzním laserem a čisticího stroje s kontinuální vlnou (CW).

Rozdíl mezi čištěním pulzním laserem a čištěním CW laserem (kontinuální čištění laserem)

Scénáře z reálného světa: Výběr správného nástroje pro danou práci

Podívejme se na některá skutečná pracovní místa.

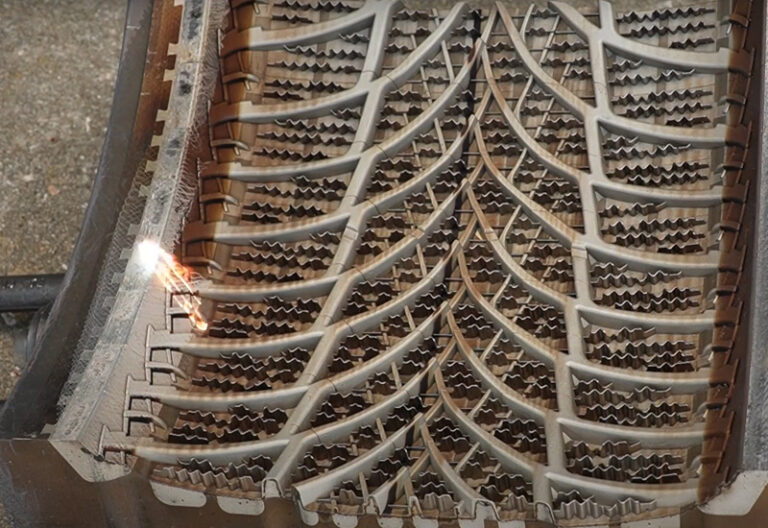

Pro choulostivé práce s vysokou hodnotou

Zamyslete se nad čištěním formy na pneumatiky, desky plošných spojů nebo restaurováním staré bronzové sochy. Povrchová úprava je vše. Jakékoli poškození, deformace, změna struktury a součást je zničená. To je přesně oblast pulzního laseru. Pro tyto účely potřebujete stroj, který nabízí maximální kontrolu, např.

1000W pulzní laserový čisticí stroj or even a specialized.

Pulzní laserový čisticí stroj s laserem Raycus Max JPT zdroje, abyste mohli vybírat přesné parametry úlohy.. Nekupujete si jen čisticí prostředek, ale i pojištění svých cenných dílů.

Pro náročné, hromadné čištění

Nyní si představte loděnici, opravovaný most nebo staré potrubí pokryté roky rzi a špíny. Cíl je jednoduchý: vyčistěte ho a vyčistěte ho hned. Nikdo nebude měřit kvalitu povrchu mikroskopem. Záleží jen na rychlosti a výkonu. To je domovská půda CW laseru. Odstraní tuto rez za zlomek času, což z něj činí nákladově nejefektivnější nástroj pro rozsáhlé průmyslové scénáře. Pro práci na cestách se hodí přenosná jednotka, jako je např. Laserový čisticí stroj na vozíku může přivést výkon přesně tam, kde ho potřebujete..

Proč záleží na výběru výrobce

Podívejte, krabičku s laserem vám může prodat kdokoli. Ale stroj je jen polovina úspěchu. Jako přední Výrobce pulzního laserového čisticího stroje a Továrna na laserové čisticí stroje, my ve společnosti BOGONG Laser jsme viděli všechno. S více než 9 000 klienty ve více než 160 zemích jsme pomohli firmám ve všech odvětvích - od automobilového průmyslu přes klenotnictví až po letectví - najít ten správný nástroj.

Výběr zkušenéhoSpojitá vlna (CW) Výrobce laserových čisticích strojů znamená, že získáte víc než jen stroj. Získáte odborné znalosti. Získáte podporu. Získáte partnera, který rozumí vašim materiálům a vašim cílům. Víme, jaký je rozdíl mezi čištěním nádrže z potravinářské nerezové oceli a rezavé nápravy. Stroj, který vám doporučíme, bude ten, který vám vydělá peníze, ne ten, který vytvoří nové problémy.

Podtrženo, sečteno

Pulzní vs. kontinuální?

Volba je jednodušší, než si myslíte. Nejde o to, který z nich je "lepší". Jde o to, který z nich je vhodný pro vaši práci.

- Potřebujete přesnost, dokonalý povrch a nulové poškození? Získejte Pulsní Laserový čisticí stroj.

- Potřebujete vysokou rychlost a výkon pro náročné práce, kde nezáleží na povrchové úpravě? Získejte Laserové čisticí zařízení s kontinuální vlnou (CW).

Nedovolte, aby vám někdo prodal špatný nástroj. Porozumějte svému použití, upřímně si uvědomte své potřeby a rozhodnete se správně.