-

Shunhua Road, město Jinan, Shandong

Laserový značkovací stroj

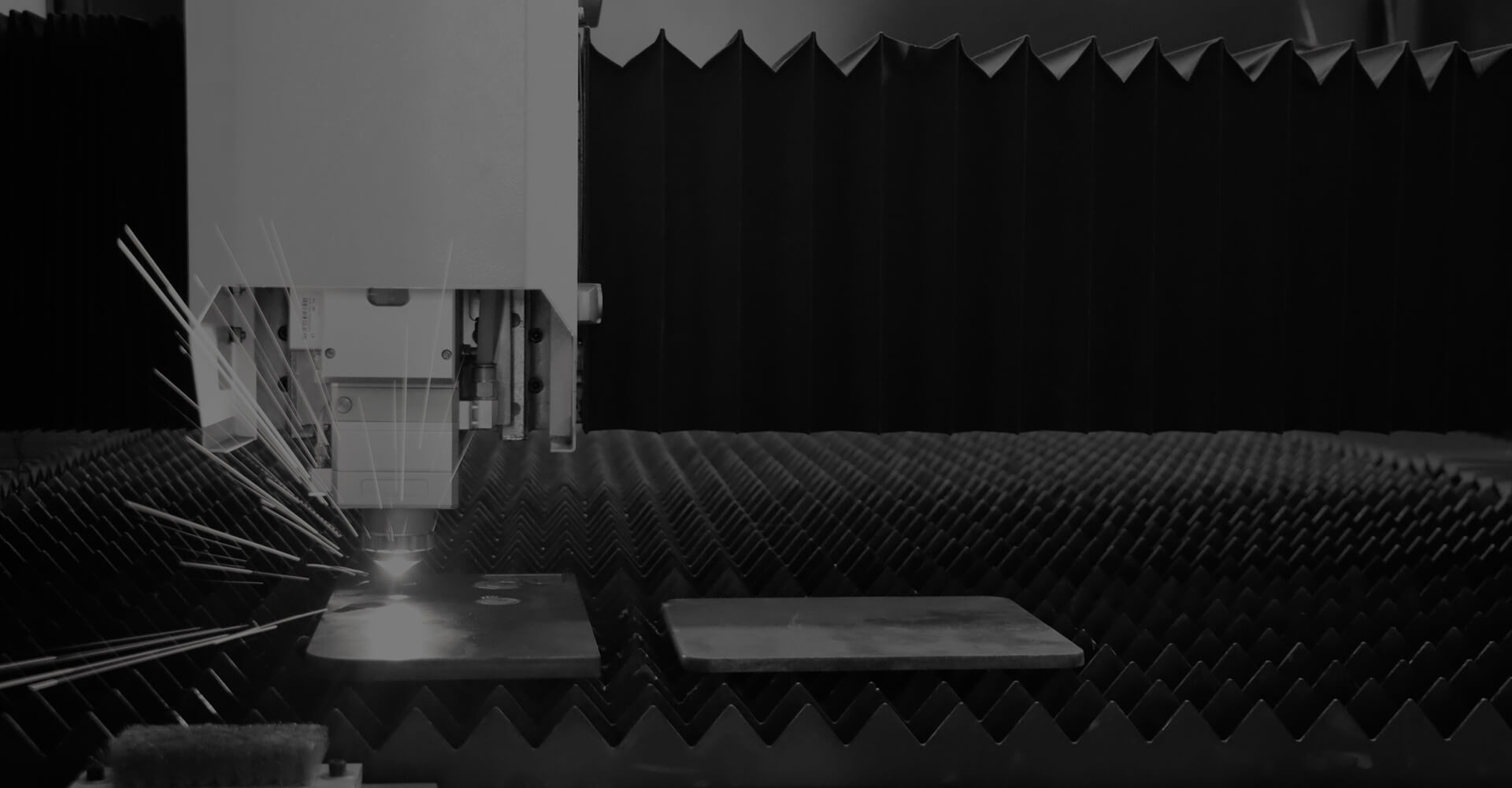

Laserový značkovací stroj používá k vyrytí trvalých značek do materiálů fokusovaný laserový paprsek. Nabízí vysokou přesnost, všestrannost a rychlost a je vhodný pro průmyslová odvětví, jako je elektronika, automobilový průmysl a lékařské přístroje, pro sériová čísla, loga a čárové kódy.

Zobrazeno 15 výsledků

2024 Nejlépe hodnocené vláknové laserové gravírovací stroje na prodej

30W vláknový laserový značkovací stroj

3D krystalový laserový gravírovací stroj | UV Pro Laser Marking Machine

3D vláknový laserový gravír pro kov

3D laserový gravírovací stroj s velkou gravírovací plochou

3D UV laserový značkovací stroj

Laserový značkovací stroj s vlákny "vše v jednom

Laserové značení CO2

Vláknový laserový stroj na hluboké gravírování kovů na prodej

Vláknové laserové gravírování řezací stroj pro kovové šperky

Laserová vrtačka na sklo | MOPA M8 Laserový řezací stroj na sklo

Mini skříňový laserový značkovací stroj

Mini Split Fiber Laser Engraving Machine

Přenosný laserový gravír

UV laserový značkovací stroj