-

Shunhua Road, město Jinan, Shandong

Často kladené otázky

ČASTO KLADENÉ OTÁZKY

Časté dotazy o laserových řezacích strojích

Bogong Laser’s cutting machines support a wide range of materials, including acrylic, glass, leather, metal, paper, plastic, wood, and sheet metal.

Řezací stroje s vláknovým laserem mohou účinně řezat různé kovy, včetně nerezové oceli, uhlíkové oceli, hliníku, mosazi, mědi a slitin.

Maximální tloušťka závisí na výkonu laseru. Máme řezný list, který ukazuje řezný výkon včetně 2000w 3000w 6000w 12000w 20000w 30000w 40000w atd.

K povinné údržbě patří pravidelné čištění objektivu, kontrola chladicího systému, kontrola zrcadel a zajištění správného seřízení stroje. Doporučujeme provádět pravidelné kontroly, aby byl stroj v optimálním stavu.

Řezací stroje s vláknovým laserem o výkonu vyšším než 3 kW obvykle vyžadují třífázové napájení s konkrétním napětím a proudem v závislosti na modelu a výkonu laseru.

Ano, řezací stroje s vláknovým laserem lze snadno integrovat do automatizovaných výrobních linek, včetně manipulačních a robotických systémů, a zvýšit tak efektivitu.

Probíhá komplexní školení, které zahrnuje obsluhu stroje, údržbu a bezpečnostní protokoly, aby byla obsluha dobře připravena.

Po skončení záruční doby nabízíme rozšířené servisní plány a možnosti podpory pro údržbu a opravy, které zajišťují trvalou pomoc.

Výroba a dodání trvá obvykle 2 až 8 týdnů v závislosti na konkrétním modelu a přizpůsobení.

Přijímáme různé způsoby platby, včetně T/T (bankovní převod) a dalších bezpečných platebních možností, které jsou určeny během procesu objednávání.

Používáme vysoce kvalitní vláknové laserové zdroje od renomovaných výrobců, jako jsou IPG, Raycus, Max, které zajišťují spolehlivý výkon a dlouhou životnost.

Zeptejte se nás

Časté dotazy k laserovým čisticím strojům

Laserové čisticí zařízení se používá k odstranění nečistot, jako je rez, barva, olej, špína a další nečistoty, z různých povrchů, aniž by došlo k poškození podkladového materiálu.

Laserové čisticí zařízení vysílá vysoce intenzivní laserové paprsky, které jsou absorbovány nečistotami na povrchu. Energie laseru způsobí, že se nečistoty odpaří nebo se naruší, což umožní účinné čištění.

Laserové čištění je často účinnější a efektivnější než tradiční metody, jako je pískování nebo chemické čištění, protože odstraňuje nečistoty bez fyzického kontaktu a minimalizuje poškození podkladového materiálu.

Laserové čištění je často účinnější a efektivnější než tradiční metody, jako je pískování nebo chemické čištění, protože odstraňuje nečistoty bez fyzického kontaktu a minimalizuje poškození podkladového materiálu.

Existují nějaké bezpečnostní obavy při používání laserového čisticího stroje?

Ano, mezi bezpečnostní problémy patří riziko vystavení laseru, které může způsobit poškození očí a popálení kůže. Správné ochranné pomůcky, včetně ochranných brýlí, a dodržování bezpečnostních protokolů jsou nezbytné.

Jakou údržbu vyžaduje laserový čisticí stroj?

Maintenance typically includes regular cleaning of laser lenses, checking cooling systems if your laser cleaning machine with water chiller, and conducting routine inspections to ensure all components are functioning properly.

100W 200W 300W pulzní laserové čističe obvykle vyžadují napájení 220V/110V, 500W 1000W 2000W pulzní laserový čistič potřebuje třífázové napájení 380V, přičemž konkrétní napětí a proud závisí na modelu. 1000W 2000W pulzní laserový čistič potřebuje 220V jednoduchý napájecí zdroj, 3000W 6000W pulzní laserový čistič potřebuje třífázový 380V napájecí zdroj.

Při výběru stroje zvažte faktory, jako jsou typy čištěných povrchů, úroveň znečištění, požadovaná rychlost čištění a dostupný zdroj energie.

Poskytujeme komplexní školení pro obsluhu, které zahrnuje obsluhu stroje, postupy údržby a bezpečnostní protokoly pro zajištění bezpečného a efektivního používání.

Po skončení záruční doby nabízíme rozšířené servisní plány a podporu, které vám pomohou s údržbou a řešením problémů vašeho stroje.

Obvyklá doba výroby a dodání je 7-10 pracovních dnů pro standardní stroj, ostatní závisí na konkrétním modelu a požadovaných úpravách.

Přijímáme různé možnosti plateb, včetně T/T (bankovní převod) a dalších bezpečných platebních metod.

Naše laserové čisticí stroje využívají vysoce kvalitní laserové zdroje od renomovaných výrobců, jako je Raycus nebo JPT MOPA Laser, které zajišťují spolehlivost a výkon.

Ano, zajišťujeme dopravu a doručení na vámi zadanou adresu a zajišťujeme správnou logistiku.

Ano

Časté dotazy o laserových gravírovacích strojích

Naše stroje mohou gravírovat různé materiály včetně kovů, dřeva, plastů, skla, kůže a keramiky.

Ano, hloubku a styl rytí lze přesně ovládat a dosáhnout tak efektů od mělkých značek až po hluboké rytiny.

Pro zajištění optimálního výkonu se doporučuje pravidelné čištění objektivu, zrcadel a pracovní plochy a pravidelná kalibrace.

Ano, laserové gravírování je trvalé, odolné proti opotřebení, vyblednutí a poškození vlivem prostředí.

Časté dotazy o laserových svářečkách

Laserové svařování je svařovací proces, který využívá vysoce výkonný laserový paprsek k roztavení a spojení materiálů, obvykle kovů, čímž vzniká pevný spoj s minimální deformací a tepelně ovlivněnými zónami.

Laserové svářečky mohou svařovat širokou škálu materiálů, včetně nerezové oceli, uhlíkové oceli, hliníku, mědi a dalších slitin.

Mezi výhody patří vyšší přesnost, nižší příkon tepla, minimální deformace, možnost svařování tenkých materiálů a vyšší rychlost zpracování, což vede ke zkrácení doby cyklu.

Používejte vhodné ochranné pomůcky, včetně ochranných brýlí, rukavic a zástěr. Zajistěte správné větrání, dodržujte bezpečnostní protokoly a dbejte na umístění tlačítek nouzového zastavení.

Pravidelná údržba zahrnuje čištění optiky, kontrolu chladicího systému, kontrolu kabelů a spojů a zajištění správné kalibrace a seřízení.

Ano, mnoho laserových svařovacích strojů lze integrovat do automatizovaných výrobních linek a zvýšit tak efektivitu a konzistenci díky robotice a dalším automatizačním technologiím.

Replacement parts can be obtained from us, or you can purchase from laser head manufacturer. It’s important to use genuine parts to ensure compatibility and performance.

Poskytujeme komplexní školení, které zahrnuje obsluhu strojů, postupy údržby, bezpečnostní postupy a techniky odstraňování závad, abychom zajistili efektivní používání zařízení.

The lead time for production and delivery is typically 5-10 working days for standard machine. Others depending on the specific model and any customization requested.

Přijímáme různé platební metody včetně T/T (bankovní převod) a dalších bezpečných možností na základě preferencí zákazníka.

Raycus, Max Laserový zdroj k dispozici. IPG volitelně.

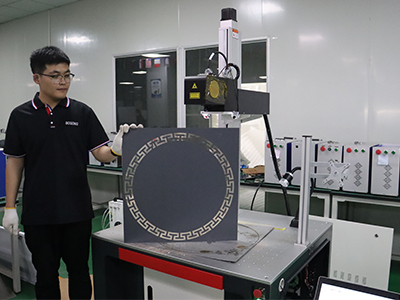

Časté dotazy o laserových značkovacích strojích

Naše stroje mohou značit na kovy, plasty, sklo, kůži, dřevo a další materiály a poskytují jasné a trvalé značení.

Ano, laserové značení je obecně trvalé a odolné proti opotřebení, vyblednutí a vlivům prostředí, což zaručuje dlouhou životnost.

Laserové popisovací stroje mohou vytvářet různé typy značení, včetně textu, log, čárových kódů, QR kódů, sériových čísel a složitých vzorů.

Poskytujeme výukové programy a manuály, které vám pomohou naučit se ovládat laserový stroj a software, a naši pracovníci, kteří mluví anglicky, vás mohou vést jeden po druhém.

Vždy používejte vhodné ochranné brýle, zajistěte správné větrání a dodržujte bezpečnostní protokoly. Dávejte pozor na provozní oblast laseru a v případě potřeby používejte ochranné štíty.

Pravidelná údržba zahrnuje čištění čoček, kontrolu seřízení, kontrolu chladicích systémů, pokud jsou vybaveny vodním chladičem, a aktualizace softwaru pro zajištění optimálního výkonu.

Laserové značení lze provádět na povrchu válce pomocí rotačního zařízení.

Software EZCAD, Může podporovat běžné formáty souborů, jako jsou DXF, AI a PLT.

Obvykle nabízíme dvouletou záruku, technickou podporu a přístup k náhradním dílům během záruční doby.

Po skončení záruční doby jsou k dispozici rozšířené servisní plány a možnosti podpory pro údržbu a opravy.

Doba výroby a dodání se obvykle pohybuje od 5 do 7 pracovních dnů, kontaktujte tým BOGONG a zeptejte se, zda je stroj skladem.

Ano, poskytujeme instruktážní videa s ukázkami obsluhy laserového značkovacího stroje, včetně nastavení, obsluhy a údržby.

Chcete-li zadat objednávku, můžete kontaktovat náš prodejní tým a prodiskutovat s ním své požadavky, získat cenovou nabídku a doladit podrobnosti objednávky. Provedeme vás celým procesem.